Rail double-power working vehicle

A dual-power, working vehicle technology, applied to motor vehicles, electric vehicles, electric locomotives, etc., can solve problems such as energy waste, environmental pollution, and low efficiency, and achieve the effects of flexible operation, high running precision, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] figure 1 In the vehicle body 1, components such as auxiliary inverters, fuel tanks, and braking components can be arranged under the vehicle body 1, and an operating system 5 is arranged on the vehicle body 1. The bogie 2 is located at the lower part of the car body 1, and a traction motor is installed on the bogie 2, and the traction motor drives the wheel pair through a gear box fixed on the wheel pair. There are two front and rear consoles in the cab 3, and the driver can control the running of the vehicle through any console. In the machine room 4, power storage devices, traction inverters, auxiliary inverter power supplies, etc. are placed. The operating system 5 includes an operating device and an operating system operating device.

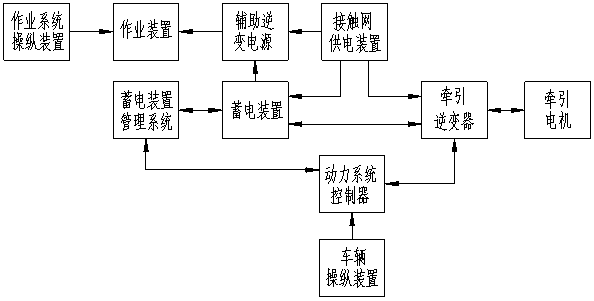

[0016] figure 2 In the power system controller, the power system controller receives instructions from the vehicle operating device, and connects with the power storage device management system and the traction inverter to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com