A heat dissipation structure for a water pump motor driver

A technology of water pump motor and heat dissipation structure, which is applied to the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., which can solve the problems of high energy consumption, reduced service life of drivers, and high operating frequency of electronic components, and achieve effective results Good, improved cooling effect, simple structure, convenient and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

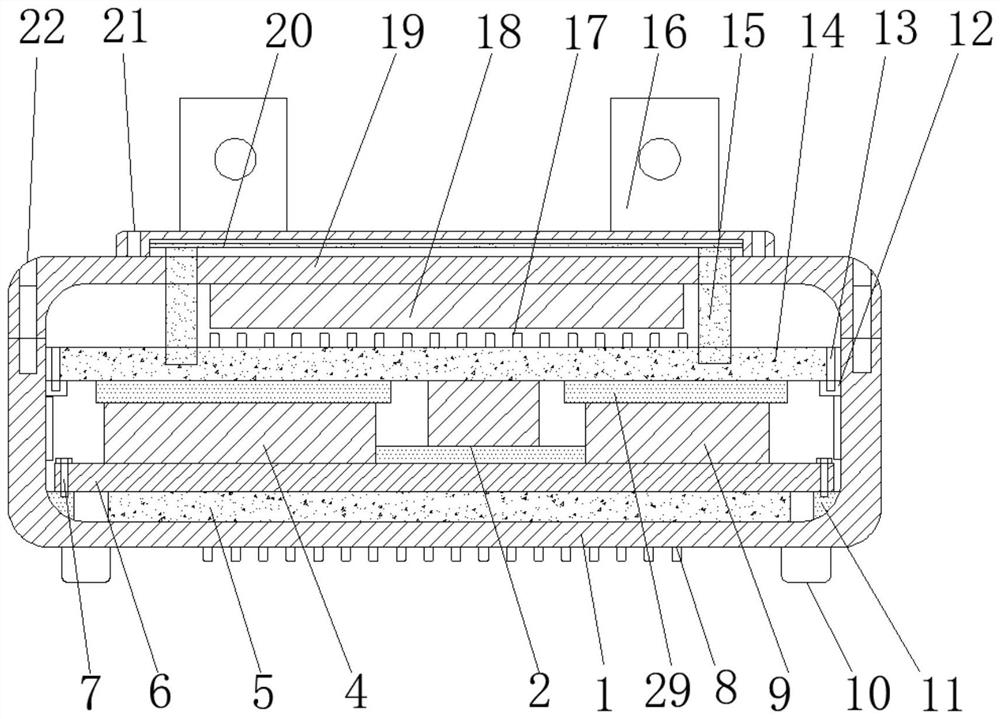

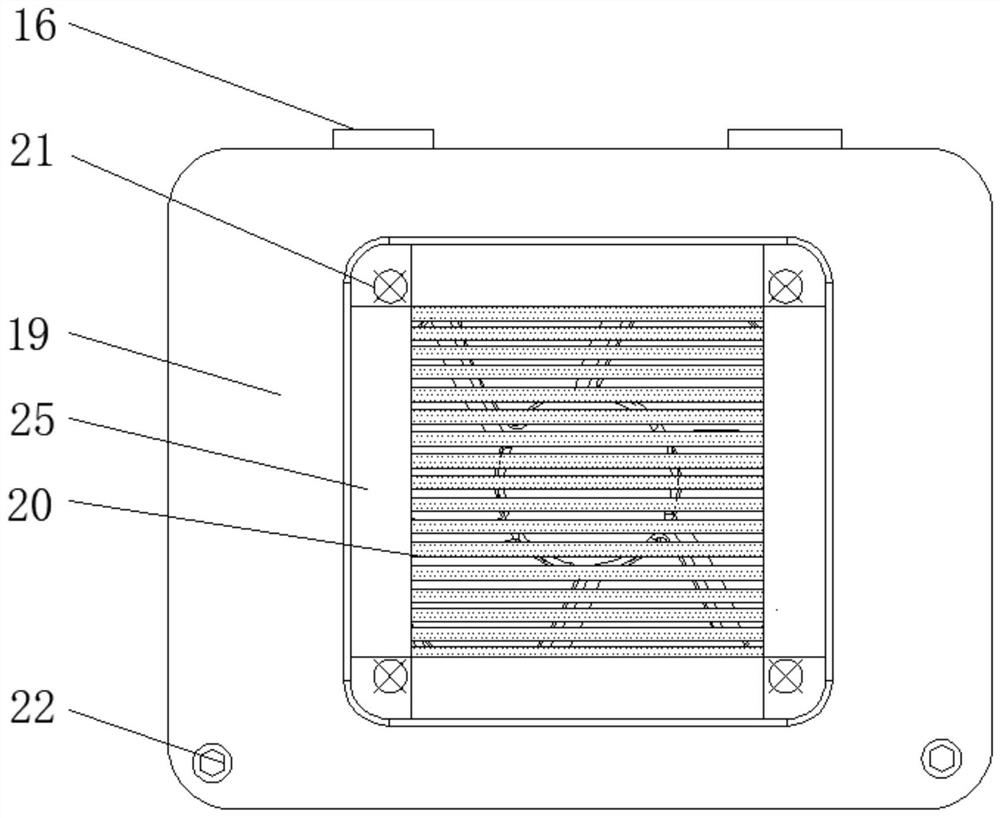

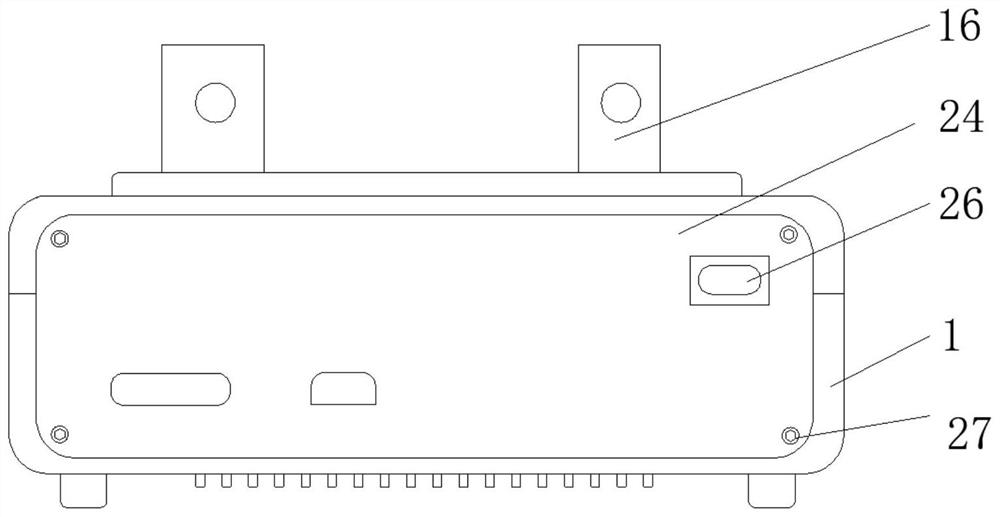

[0019] see Figure 1-4 , the present invention provides a technical solution: a heat dissipation structure for a water pump motor driver, including a first housing 1, four first fixing blocks 11 are symmetrically welded on the inner bottom wall of the first housing 1, four first fixing blocks 11 are welded symmetrically, The upper surface of a fixed block 11 is fixedly connected with the circuit board 6 through the first bolt 7, the upper surface of the circuit board 6 is fixedly connected with the first electronic component 4 and the second electronic component 9, the first electronic component 4 and the second electronic component The upper surface of 9 is bonded with a third thermal pad 29, and the inner wall of the first housing 1 is symmetrically welded with two second fixing blocks 12, and the upper surfaces of the two second fixing blocks 12 are fixed by second bolts 13 A copper heat conduction plate 14 is connected, the lower surface of the copper heat conduction plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com