Automatic adjusting mechanism and adjusting method for seal console fill-in light

A technology of automatic adjustment and fill light, applied in TV, color TV parts, electrical components, etc., can solve problems such as insufficient light, recognition, affecting document content inspection, etc., to achieve clear photos, improve compatibility, and avoid waste. The effect of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

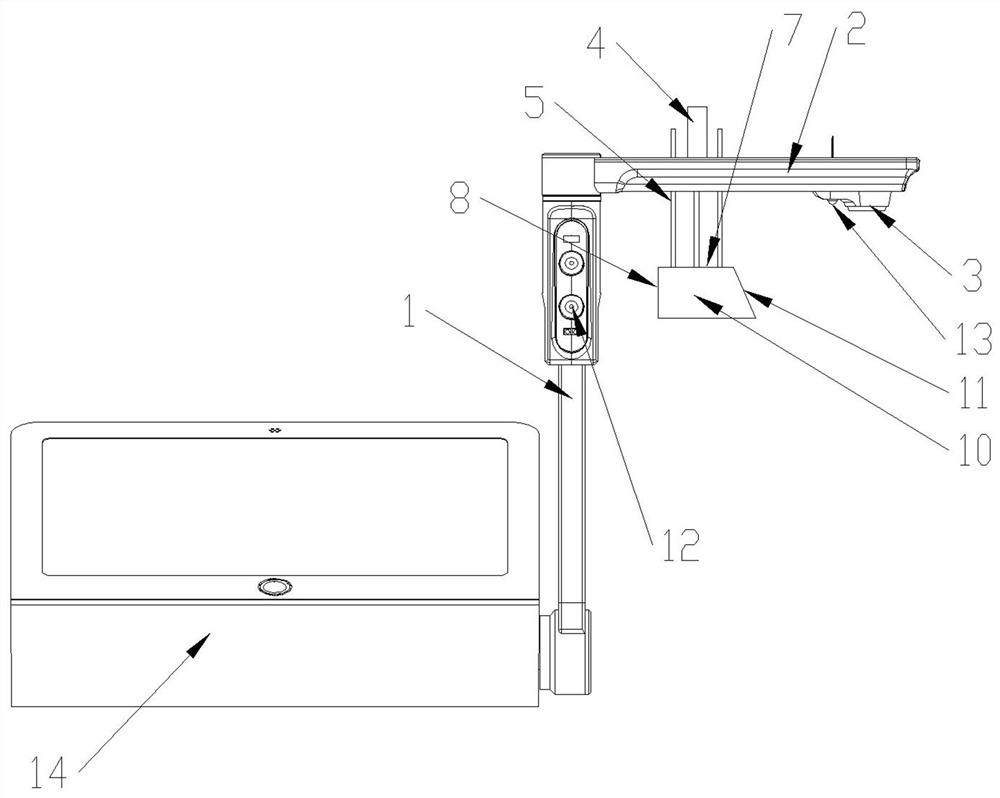

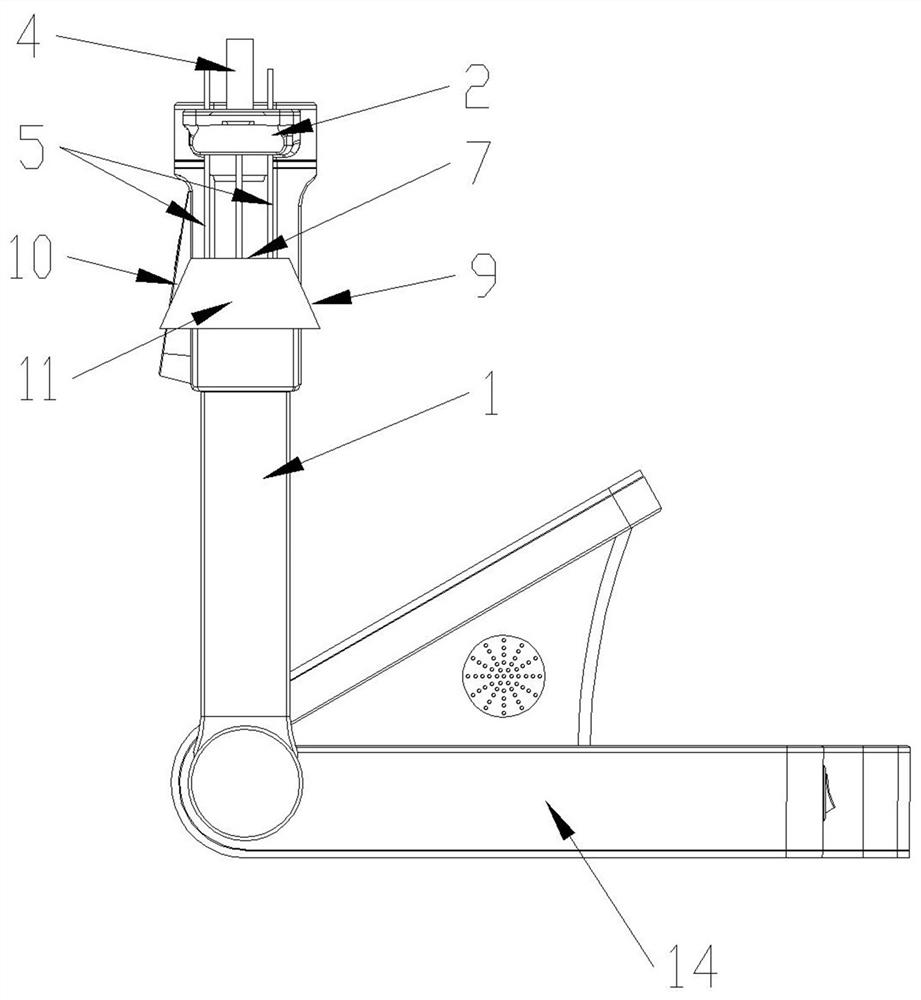

[0019] like figure 1 and figure 2 As shown, in this embodiment, the present invention includes a swing arm, an adjustment module and a supplementary light assembly, the swing arm includes a first swing arm 1 and a second swing arm 2, and one end of the first swing arm 1 rotates Fitted on the main console 14, the second swing arm 2 is rotatably fitted on the other end of the first swing arm 1, and the adjustment module includes a document recognition camera 3, a cylinder 4 and several guide columns 5, so Both the document recognition camera 3 and the cylinder 4 are arranged on the second swing arm 2, the supplementary light assembly includes a housing and a supplementary light, the supplementary light is built in the housing, the The cylinder 4 is connected to the housing in transmission, the guide column 5 is connected to the housing after passing through the second swing arm 2, and the document recognition camera 3 is connected to the cylinder 4 through the main console 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com