Cigarette box appearance defect detection system

A technology of appearance defects and detection system, which is applied in the field of detection, can solve the problems of cigarette packs flowing into the market, low detection efficiency, and easy fatigue, etc., and achieve the effect of accurate detection results and clear pictures of cigarette pack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

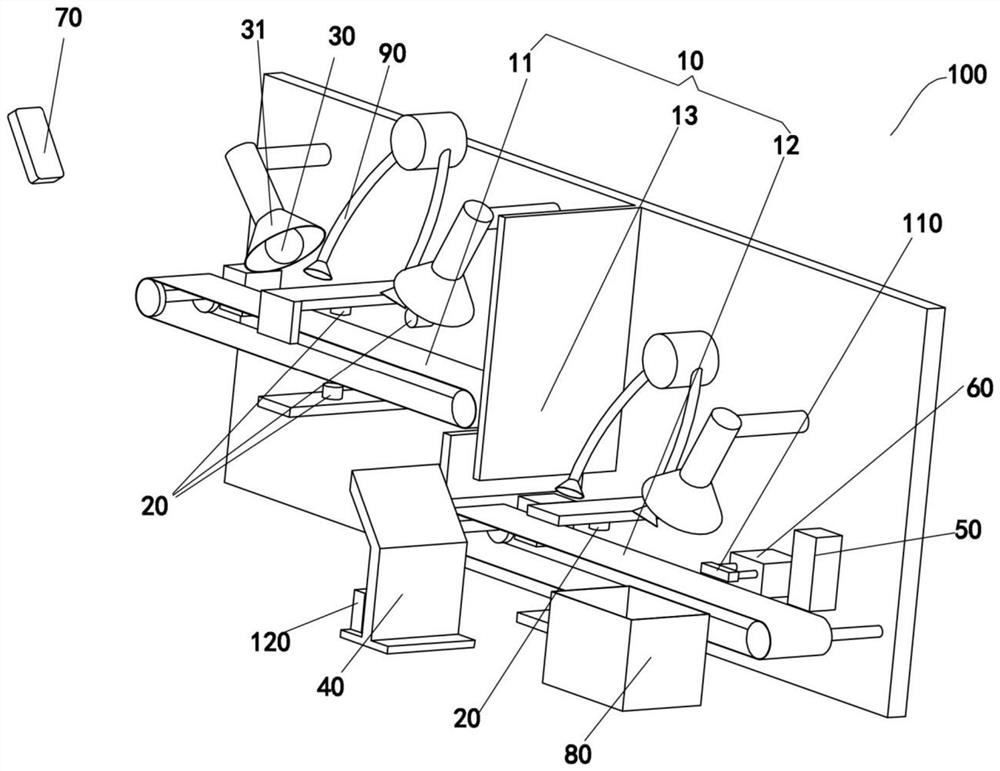

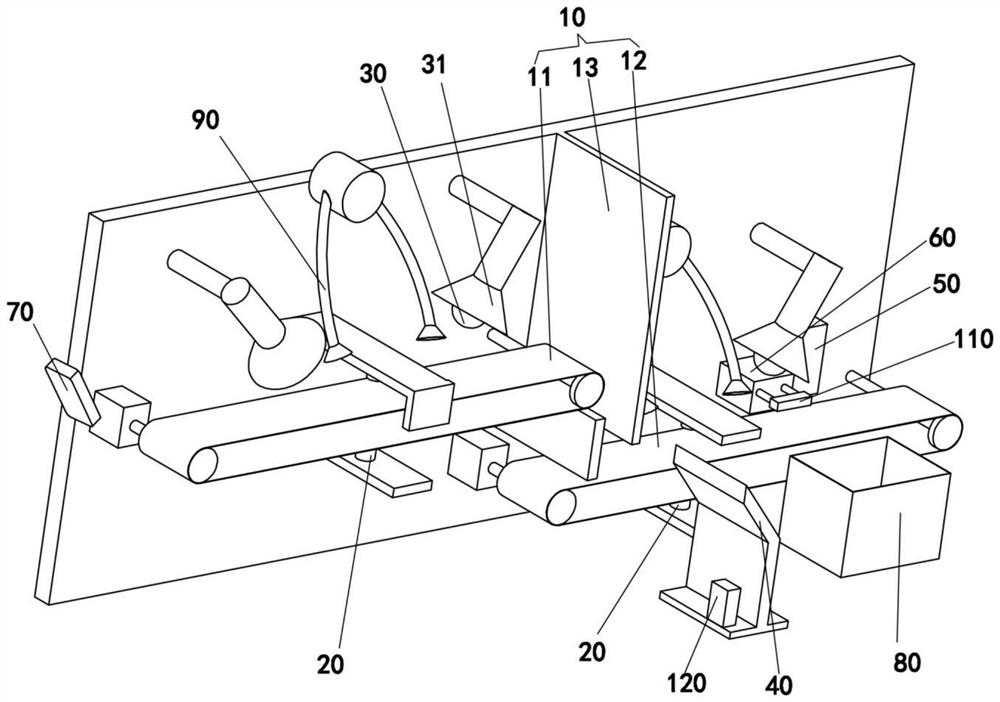

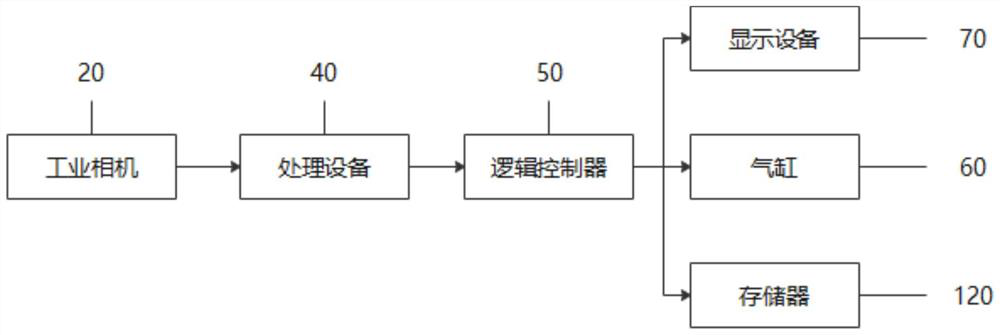

[0024] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can understand the advantages and effects of the present invention from the content disclosed in this specification. It should be noted that the diagrams provided in the following examples are for illustrative purposes only, and are only schematic diagrams rather than actual pictures, and should not be construed as limitations on the present invention. In order to better illustrate the embodiments of the present invention , some components in the figure will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art, it is understandable that some known structures and their descriptions in the figure may be omitted.

[0025] The same or similar symbols in the figures of the embodiments of the present invention correspond to the same or similar components. In the description of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com