Process method for manufacturing post-manufactured electrodes of photovoltaic cell

A technology of photovoltaic cells and process methods, applied in the directions of photovoltaic power generation, duplication/marking methods, sustainable manufacturing/processing, etc., can solve problems such as difficulty in shingling, high cost of customization, and non-common use of shingling cell formats, to prevent The effect of over-sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

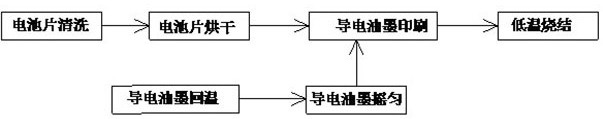

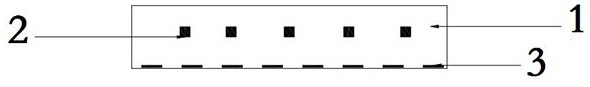

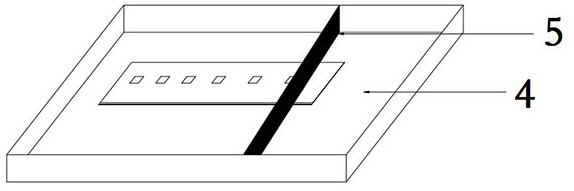

[0024] A kind of process method of post-production electrode of photovoltaic cells, with reference to Figure 1-3 , which includes the following several technological processes: 1. Cell cleaning; 2. Cell drying; 3. Conductive ink reheating; 4. Shaking conductive ink; 5. Printing of conductive ink; 6. Low temperature sintering;

[0025] Specifically, the cleaning of the cell is performed by using absolute ethanol or a volatile anhydrous organic cleaning agent to clean the cell 1 to remove surface contamination.

[0026] The cells are dried, and the cleaned cells 1 are baked in an oven at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com