On-duty flame stabilizing cavity of trapped vortex combustion chamber and oil-gas matching device

A technology for matching devices and combustion chambers, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as unsatisfactory oil and gas mixing, and achieve the effect of improving lean oil flameout limit, increasing effective combustion time, and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

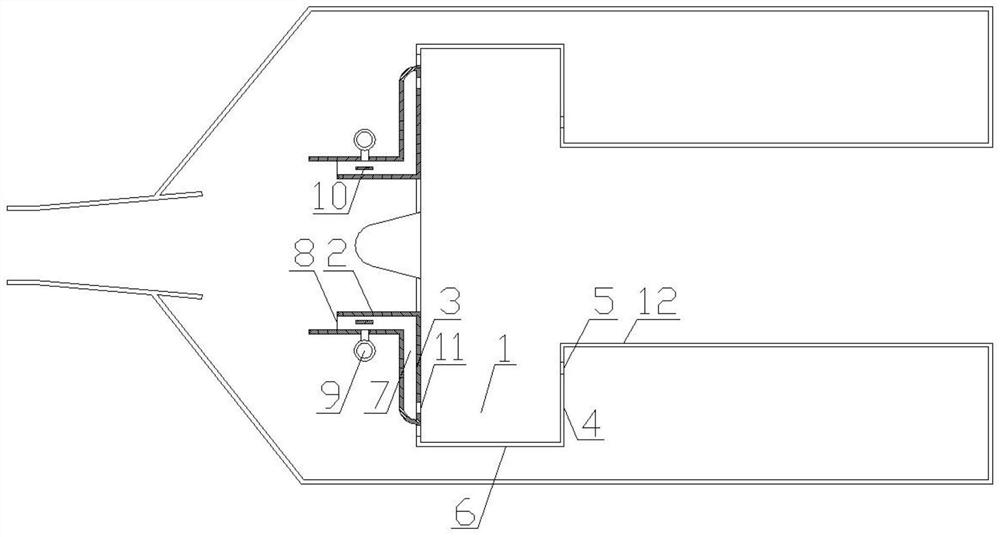

[0018] The reference signs in the drawings of the description include: cavity 1, deflector 2, cavity front wall 3, cavity rear wall 4, second air inlet 5, cavity bottom wall 6, premixing cavity 7, the first An air inlet 8, an oil supply pipe 9, an oil splash plate 10, an oil injection hole 11, and a combustion chamber 12.

[0019] The embodiment is basically as attached figure 1 Shown: a vortex combustor 12 on-duty flame-stabilizing concave cavity 1 and an oil-gas matching device, including a concave cavity 1 with a top opening and a deflector 2 located on the front wall of the concave cavity 1, the rear wall of the concave cavity 1 and the combustion chamber 12. The side wall is made by one-piece molding process. The length of the front wall of the cavity 1 is greater than the length of the rear wall of the cavity 1. Both the front wall and the rear wall of the cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com