A municipal road pipe jacking construction safety equipment and its construction method

A technology for municipal roads and safety equipment, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc., can solve problems such as lack of effective guidance, pipe jacking damage, pipe axis deviation, etc., and achieve stable progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

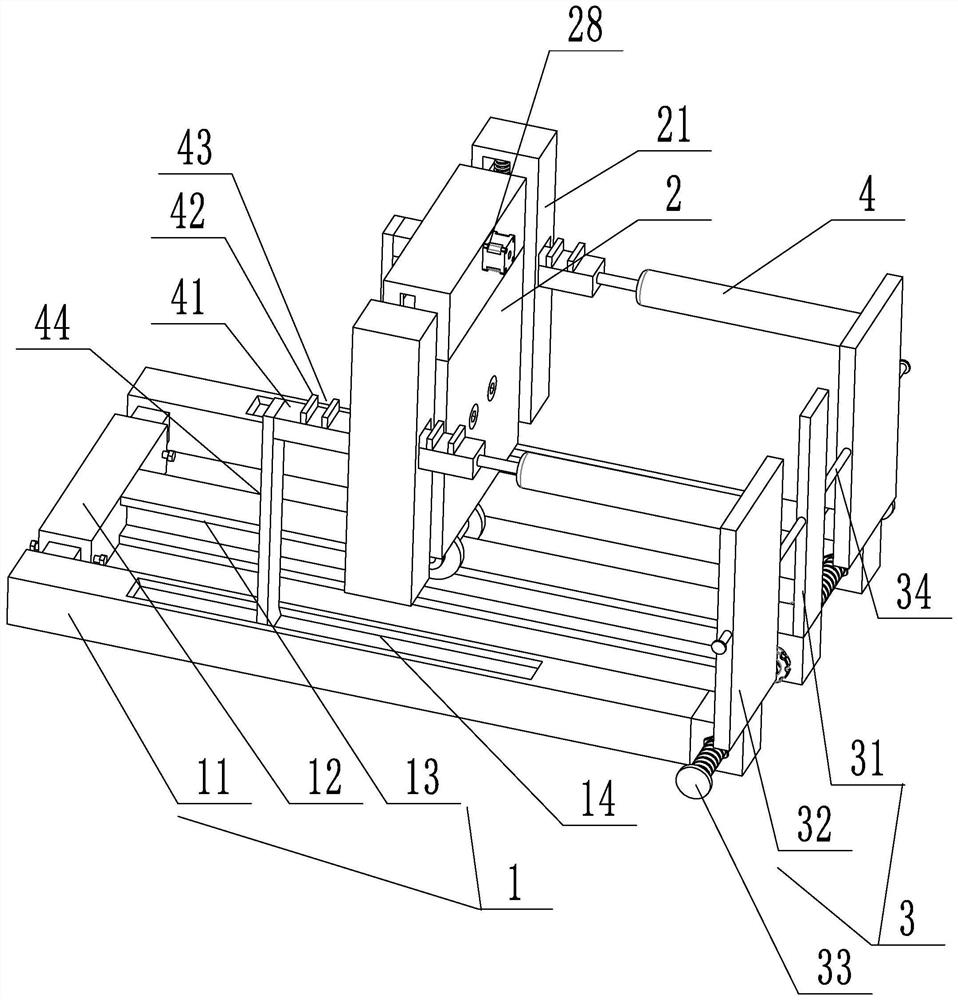

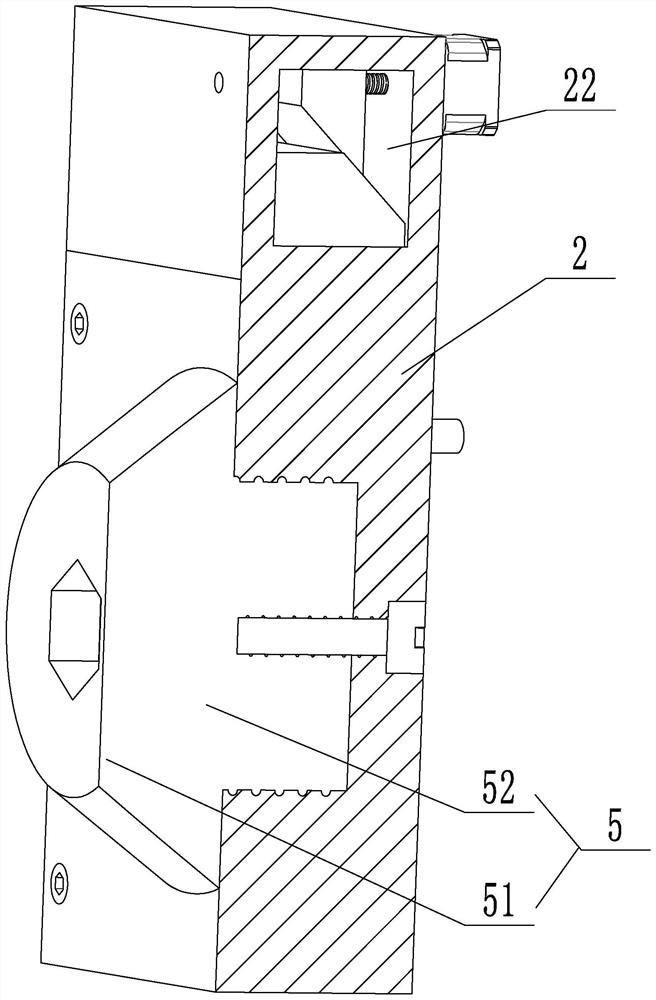

[0040] Embodiment one, with reference to figure 1 , is a municipal road pipe jacking construction safety equipment disclosed by the present invention, including a base 1, a sliding seat 2 slidably installed on the base 1, a bottom plate 3 fixed on the end of the base 1, and two hydraulic pressure points installed on the bottom plate 3. Cylinder 4.

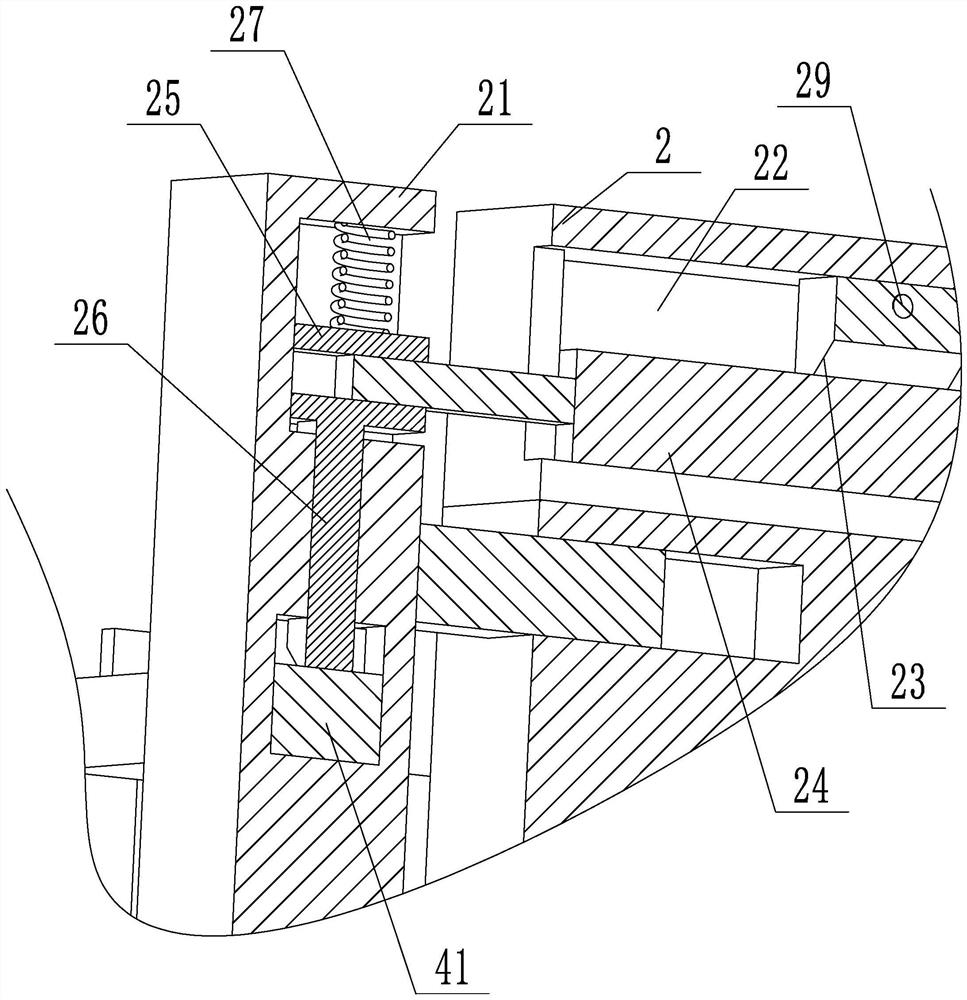

[0041] refer to figure 1 , figure 2 Ejector 5 is installed on the sliding seat 2, the outer fixed sleeve of the movable rod of the hydraulic cylinder 4 is provided with a guide sleeve 41, the two sides of the sliding seat 2 are provided with a connecting sleeve 21, and the connecting sleeve 21 is provided with a passage for the guiding sleeve 41 to pass through. Through holes, the guide sleeve 41 is formed with three limit pieces arranged along its length direction. The limit pieces include two limit blocks 42, and a card slot 43 is formed between the limit blocks 42, and the connecting sleeve 21 is movable. There is a clamping...

Embodiment 2

[0047] Embodiment 2, the present invention discloses a construction method of pipe jacking safety equipment on municipal roads, including the following steps:

[0048] Step 1. Place the excavated jacking pipe on the base 1. The end of the jacking pipe and the round platform 51 on the ejector 5 cooperate with each other. The guide sleeves 41 are located on both sides of the jacking pipe for guidance, and the sliding seat 2 pushes the jacking pipe against it. tight;

[0049] Step 2, the hydraulic cylinder 4 works to make the guide sleeve 41 slide in the through hole, the drive motor 28 works to make the block 26 move down and act on a slot 43 close to the hydraulic cylinder 4, and the hydraulic cylinder 4 enters the extended state Make the sliding seat 2 slide, push the jacking pipe to the designated position, and the guide sleeve 41 continues to play the role of protection and guidance during the pushing process;

[0050] Step 3: The drive motor 28 rotates in the opposite dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com