Self-cleaning stop valve

A shut-off valve, self-cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, lift valves, etc., can solve problems such as leakage, the valve disc cannot be completely closed, and the effect of the shut-off valve is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

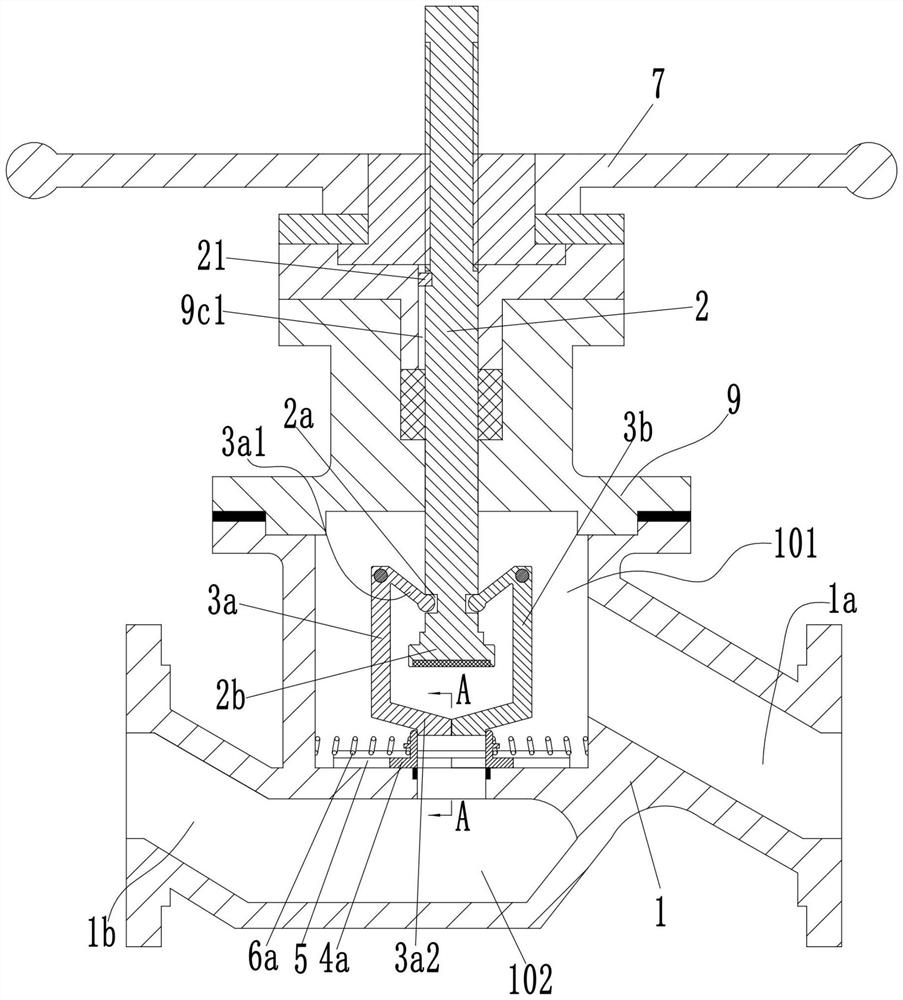

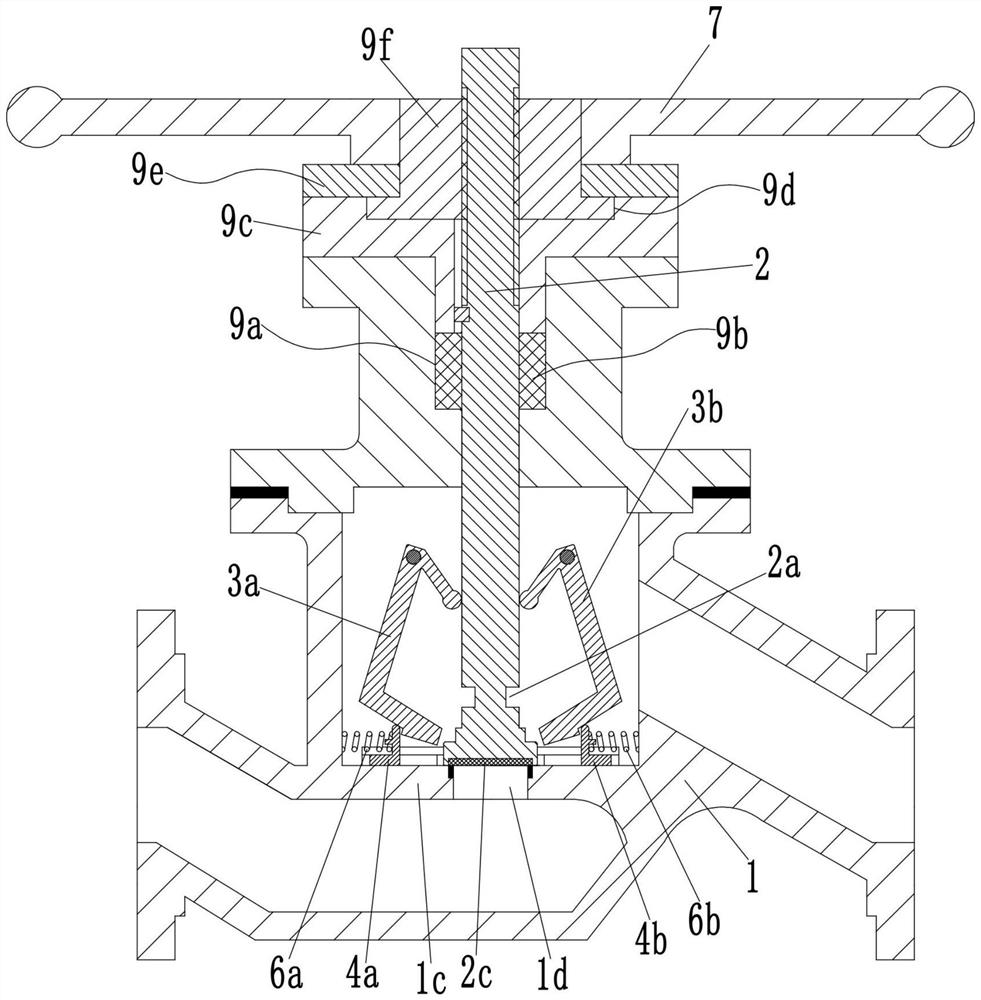

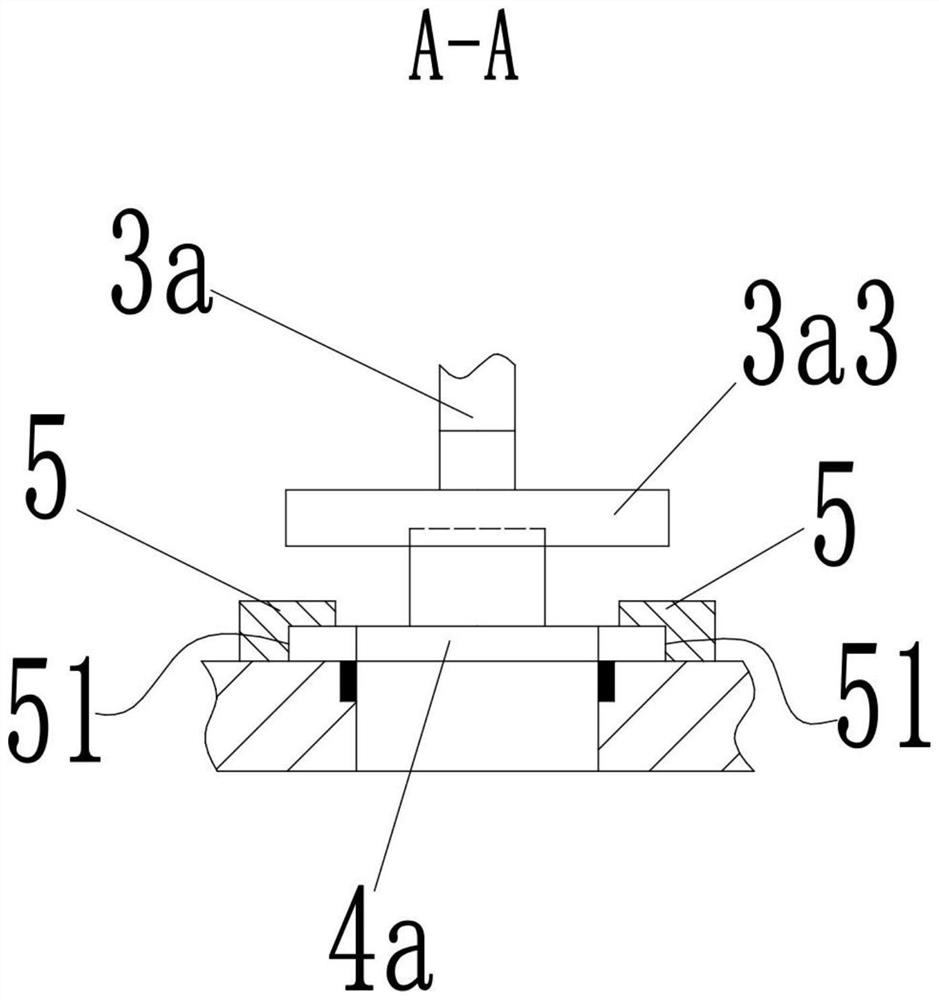

[0021] see Figure 1-7 As shown, a self-cleaning globe valve includes a valve body 1, an upper valve chamber 101 and a lower valve chamber 102 are arranged in the valve body 1, and the valve body 1 is arranged between the upper valve chamber 101 and the lower valve chamber 102. There is a valve plate 1c between them, and the valve plate 1c is provided with a valve hole 1d for connecting the upper valve chamber 101 and the lower valve chamber 102, and the side of the valve body 1 is provided with an outlet pipe 1a communicating with the upper valve chamber 101 , and the inlet pipe 1b communicating with the lower valve cavity 102; the upper opening of the upper valve cavity 101 is fixedly equipped with a valve cover 9, and the valve cover 9 is provided with a valve stem 2 along a direction perpendicular to the valve plate 1c, so The lower end of the valve stem 2 extends into the upper valve cavity 101 and is provided with a valve flap 2b for controlling the on-off of the valve h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com