Feed processing and puffing device

An extruding device and feed processing technology, applied in feed, chemical instruments and methods, solid separation, etc., can solve the problems of raw material agglomeration, hopper blockage, etc., and achieve the effect of improving use efficiency, avoiding blockage, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

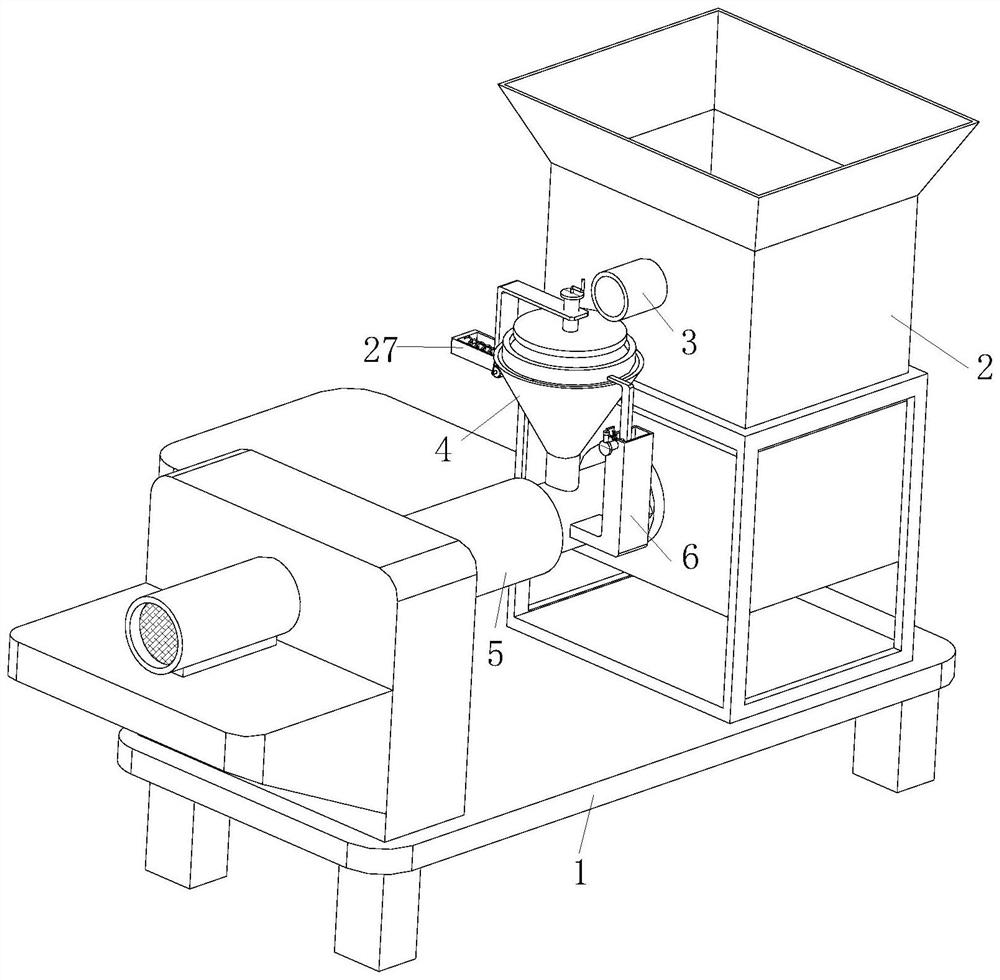

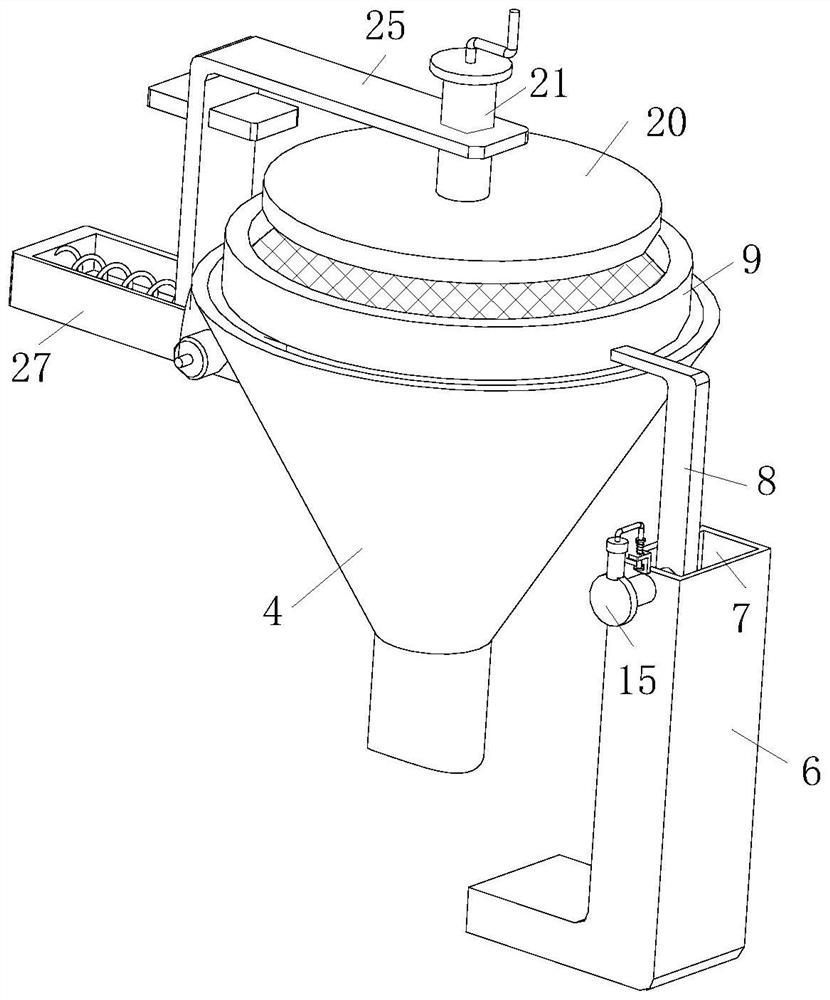

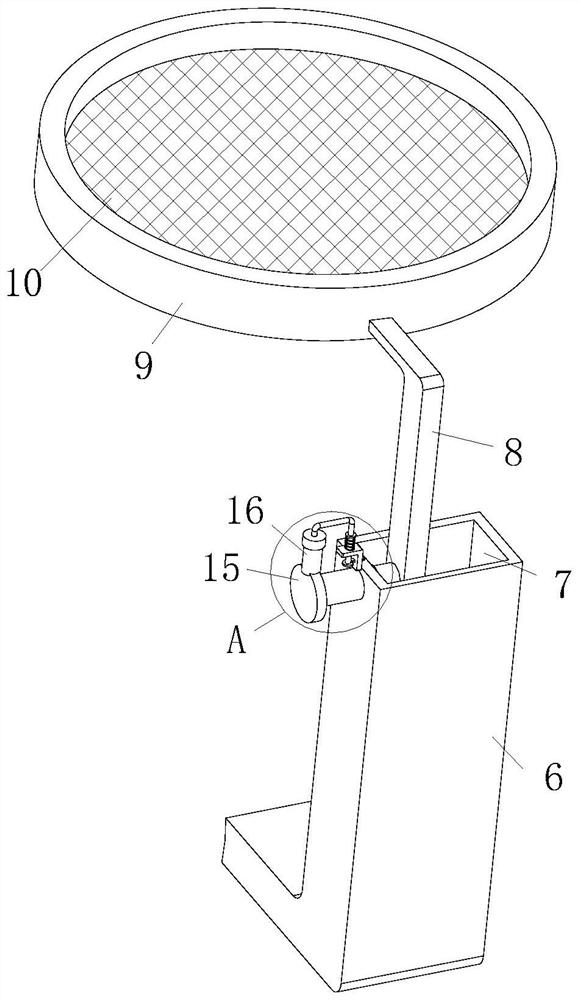

[0027] see Figure 1-5As shown, a feed processing puffing device includes a base plate 1 and a mixer 2; the mixer 2 is installed on the top of the base plate 1 by means of a bracket, and one side of the mixer 2 is connected with a discharge port 3 and a feeding pipe 5, so The feeding pipe 5 is connected with a hopper 4, the surface of the feeding pipe 5 is fixedly connected with a support block 6, and the support block 6 is "L" shaped, and the long arm end of the support block 6 is provided with a chute 7 , the inner wall of the chute 7 is slidingly connected with a slider 8, the slider 8 is "L" shaped, and the short arm end of the slider 8 is fixedly connected with a connecting ring 9, and the inner wall of the connecting ring 9 is fixed Connected with a screen 10, one side of the support block 6 is inserted with an electric telescopic rod 19, and the side of the slider 8 corresponding to the electric telescopic rod 19 is provided with a card slot, and one end of the electric...

Embodiment 2

[0036] see Figure 6 As shown in Comparative Example 1, as another embodiment of the present invention, the sliding plate 25 is slidingly connected to the limiting plate 24; when working, by pulling the round rod 21, the round rod 21 drives the cleaning disc 20 to slide upward, Then the limiting plate 24 is promoted, so that the limiting plate 24 blocks the cleaning disc 20, so that the limiting disc 22 is limited by the blocking of the limiting plate 24, which plays the role of limiting the cleaning disc 20, and then pulls the limiting plate plate 24, so that the limiting plate 24 no longer blocks the cleaning tray 20, and then the cleaning tray 20 is moved.

[0037] The working principle is that by pulling the limit block 31, the limit block 31 no longer blocks the connection plate 14. At this time, the first spring 12 will push the disc 11 due to the recovery of the elastic force, so that the disc 11 will drive the slider 18 to slide upwards. , the slide rod 18 will drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com