A chemical hardening sand casting process

A sand casting and chemical hardening technology, applied in the field of sand casting, can solve the problems affecting the smoothness of the stirring structure, waste of raw materials, casting effects, etc., and achieve the effect of being conducive to full mixing, improving stirring effect, and improving fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

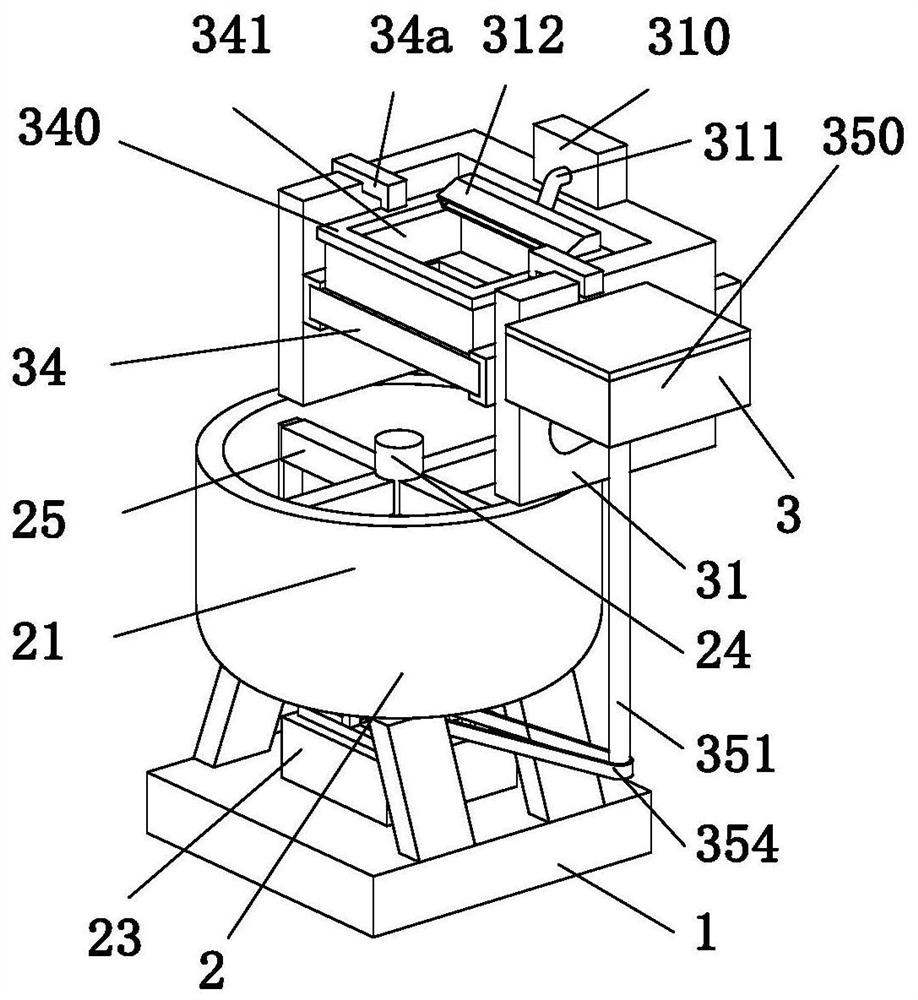

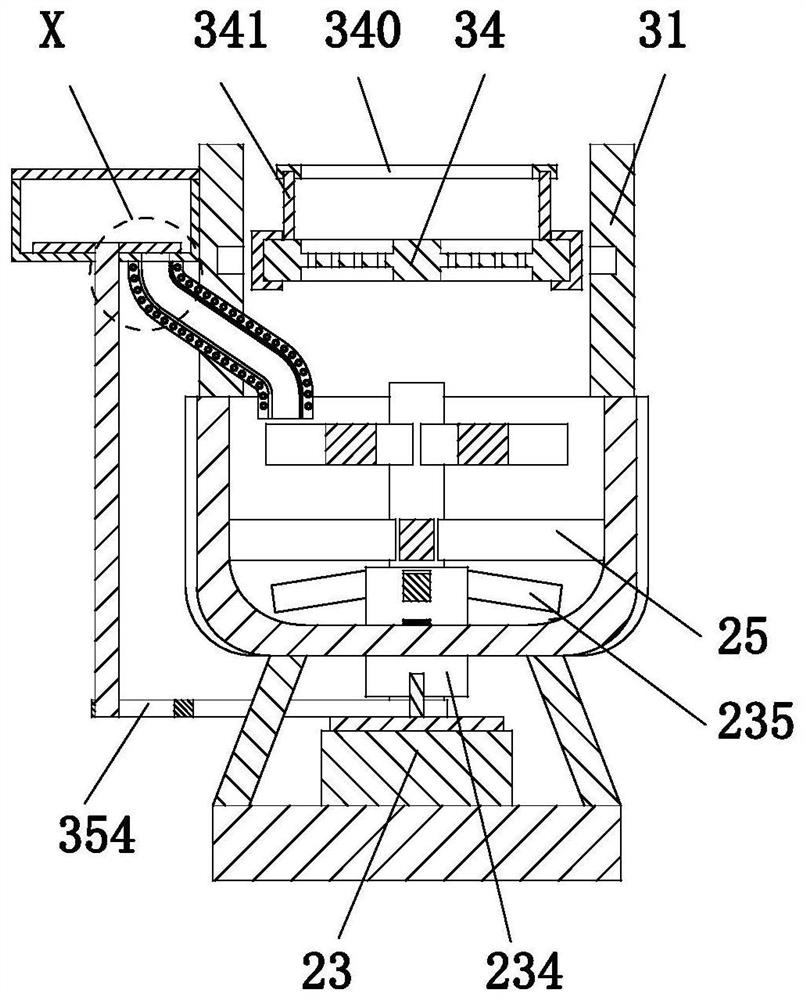

[0036] Such as Figure 1 to Figure 9 As shown, a chemical hardening sand casting process uses a chemical hardening sand casting device, the chemical hardening sand casting device includes a base 1, a stirring mechanism 2 and a feeding mechanism 3, using the above chemical hardening sand casting device for chemical The specific casting process of hardened sand casting is as follows:

[0037] S1. Adding raw sand: Pour the raw sand into the inner groove of the sieve plate 34 manually, and at the same time drive the splint 33 to reciprocate backwards through the electric slider 32, and the splint 33 drives the sieve to move synchronously to the raw sand. Screening, the raw sand in the screening falls into the mixing tank 21;

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com