Controllable two-stage flap extending system carried by blades of wind driven generator

A technology for wind turbines and control systems, which is applied to the control of wind turbines, wind turbines, and wind turbines that are in the same direction as the wind, can solve the problem that the implementation strategy cannot be taken into account.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

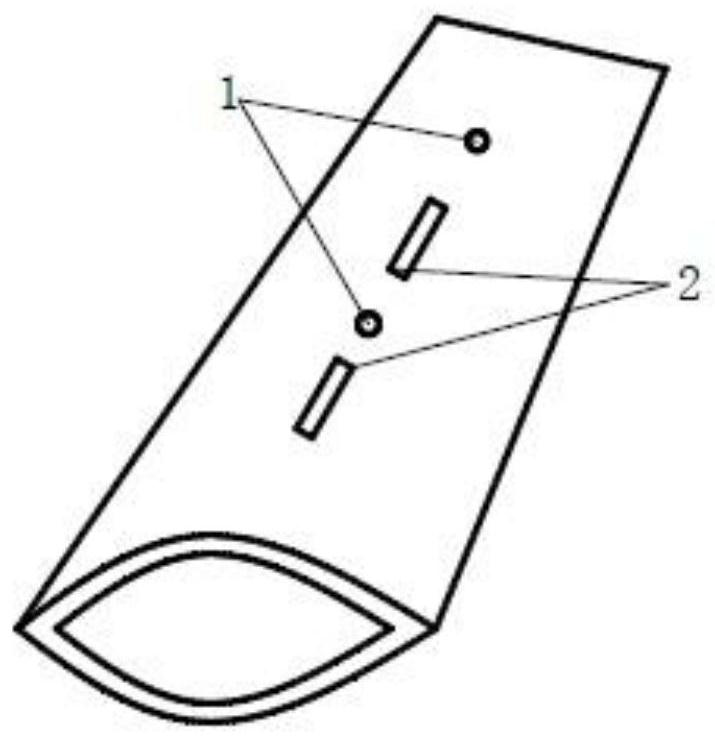

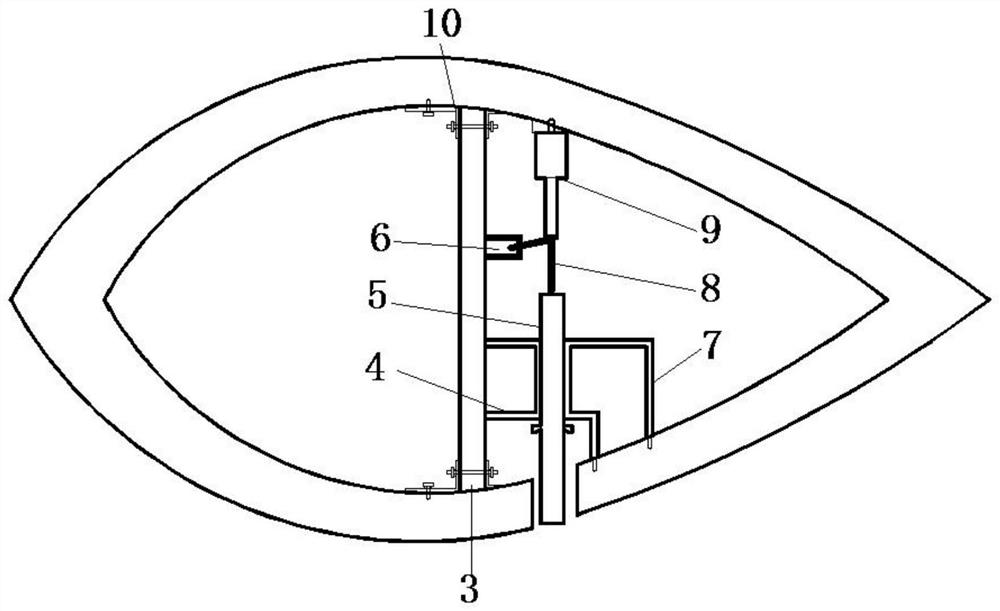

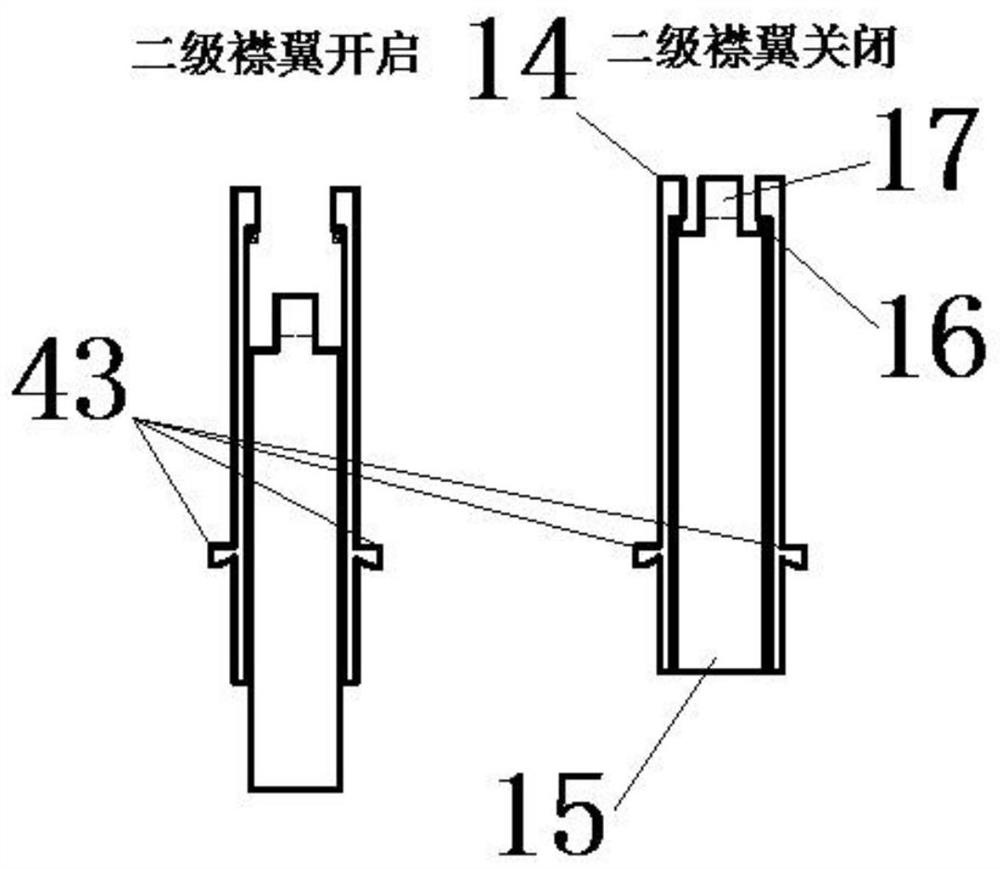

[0055] In this example, see Figure 1-Figure 14, a controllable two-stage flap extension system carried by wind turbine blades, comprising a retractable two-stage flap 5, a motor module 6, a transmission mechanism 60, a fixing frame 90 and a control system 100, the two The first-stage flap 5 and the motor module 6 are installed in the inner cavity of the wind turbine blade through the fixing frame 90, and the motor 50 in the motor module 6 is connected to drive the two-stage flap 5 through the transmission mechanism 60; the control system 100 is electrically connected to the motor 50, and then control the motor 50; the control system 100 is composed of an acceleration sensor 1 installed on the outer surface of the blade of the wind power generator and a wind speed sensor installed on the tower of the wind power generator, and the wind speed sensor is connected through a control unit 80 Control the motor 50; the control system 100 controls the motor 50 according to the wind spe...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, especially in that:

[0058] In this embodiment, first, the wind speed signal is detected by the sensor arranged on the surface of the blade, and when the wind speed meets the system start-up conditions, it is started, and the extended flaps that are fixed and limited on the fixed frame and the longitudinal fixed frame execute the outward extension of the blade. action. When the wind speed is greater than the minimum set value, the control unit outputs current to control the motor, and the motor rotates forward through the output box to drive the primary flap to extend. When the detected wind speed signal is greater than the maximum set value, the control unit continues to increase the current, and the motor performs further actions to control the extension of the secondary flaps, further increasing the length of the flaps, thereby increasing the wind resistance on the blades and reducing the blades. The vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com