Common base of diesel generator set

A diesel generator set and common base technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of large size of diesel engine, damage of diesel engine, poor lubrication, etc., to prolong flow time, reduce cavitation, reduce scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

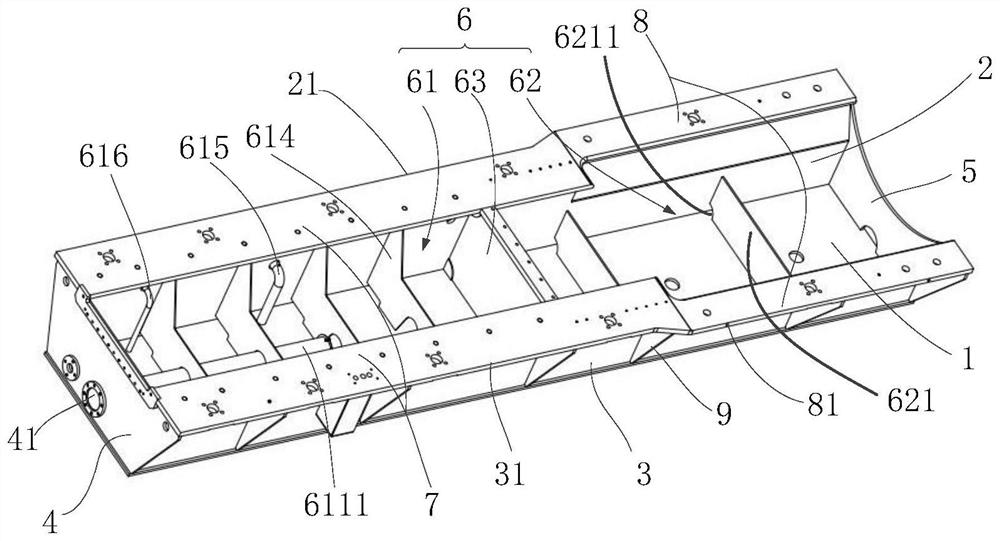

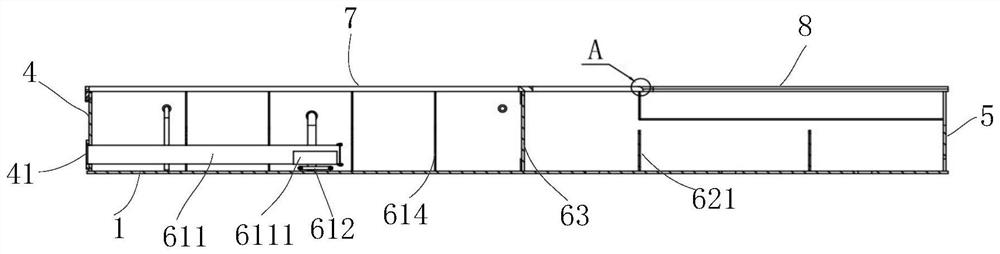

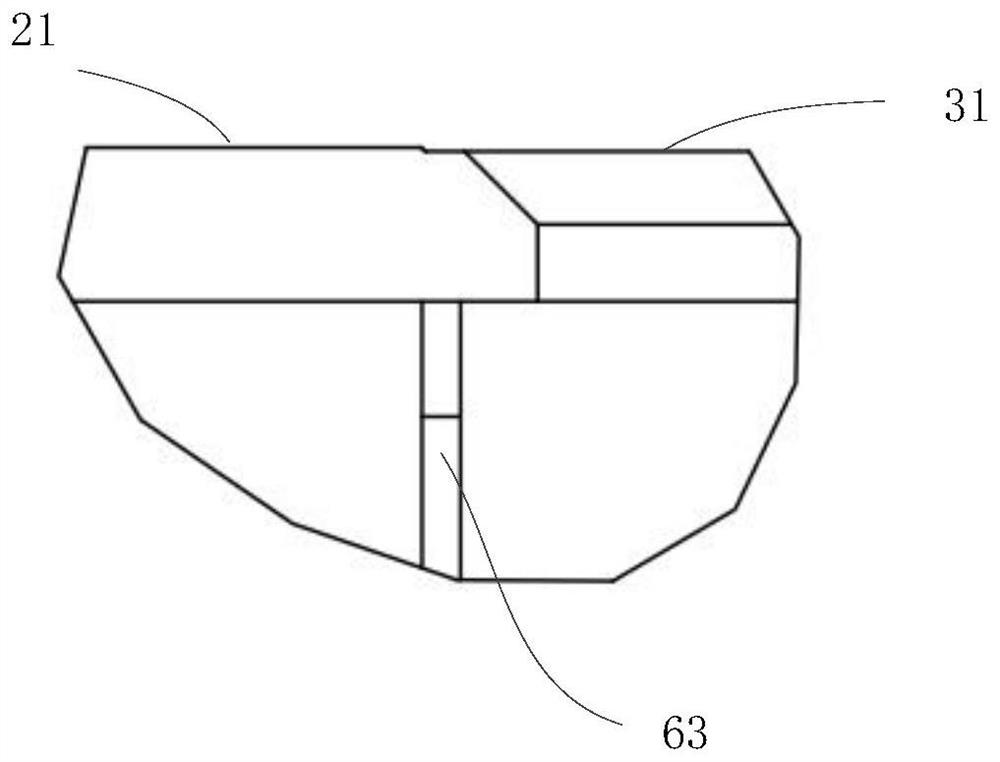

[0090] figure 1 It is a structural schematic diagram of Embodiment 1 of the diesel generating set common base of the present invention; figure 2 It is a front view cut along the axis of an embodiment of the common base of the diesel generator set of the present invention; image 3 It is an enlarged view of part A of Embodiment 1 of the common base of the diesel generator set of the present invention; Figure 4 It is a top view of Embodiment 1 of the diesel generating set common base of the present invention; Figure 5 It is a cross-sectional view at the intermediate partition of Embodiment 1 of the common base of the diesel generator set of the present invention; Figure 6 It is a cross-sectional view at the connecting plate of Embodiment 1 of the common base of the diesel generator set of the present invention; Figure 7 It is an enlarged view of Part B of Embodiment 1 of the common base of the diesel generator set of the present invention; Figure 8 It is an enlarged vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com