Steep slope high-fill roadbed structure adopting high-density EPS filler

A high-density, steep-slope technology, used in infrastructure engineering, underwater structures, paving surfaces paved with prefabricated blocks, etc., can solve the problems of high lateral pressure, easy structural instability, insufficient structural strength, etc. Small lateral deformation, good vibration reduction and isolation effect, and beneficial to mechanized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

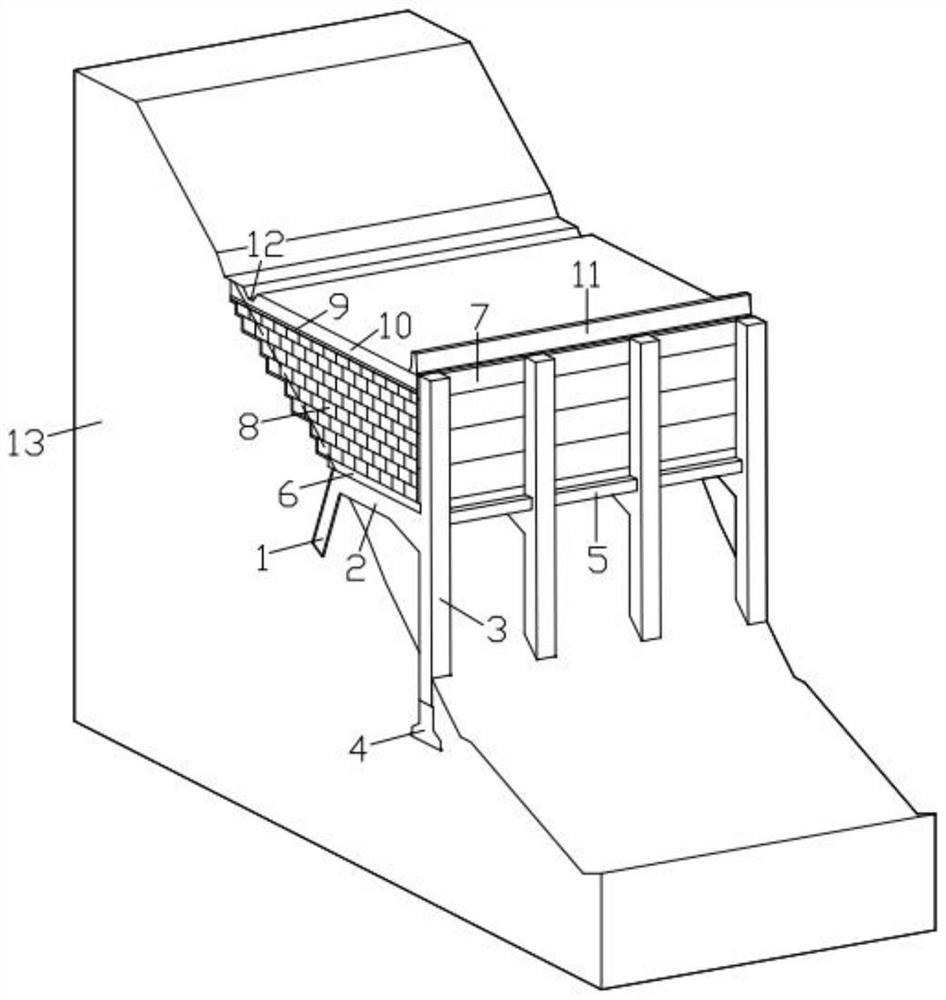

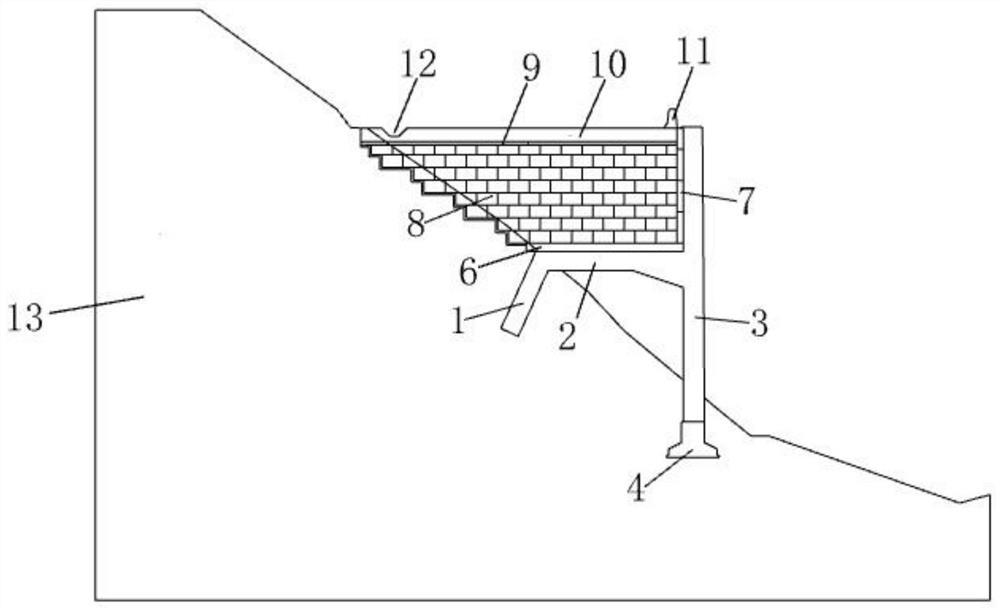

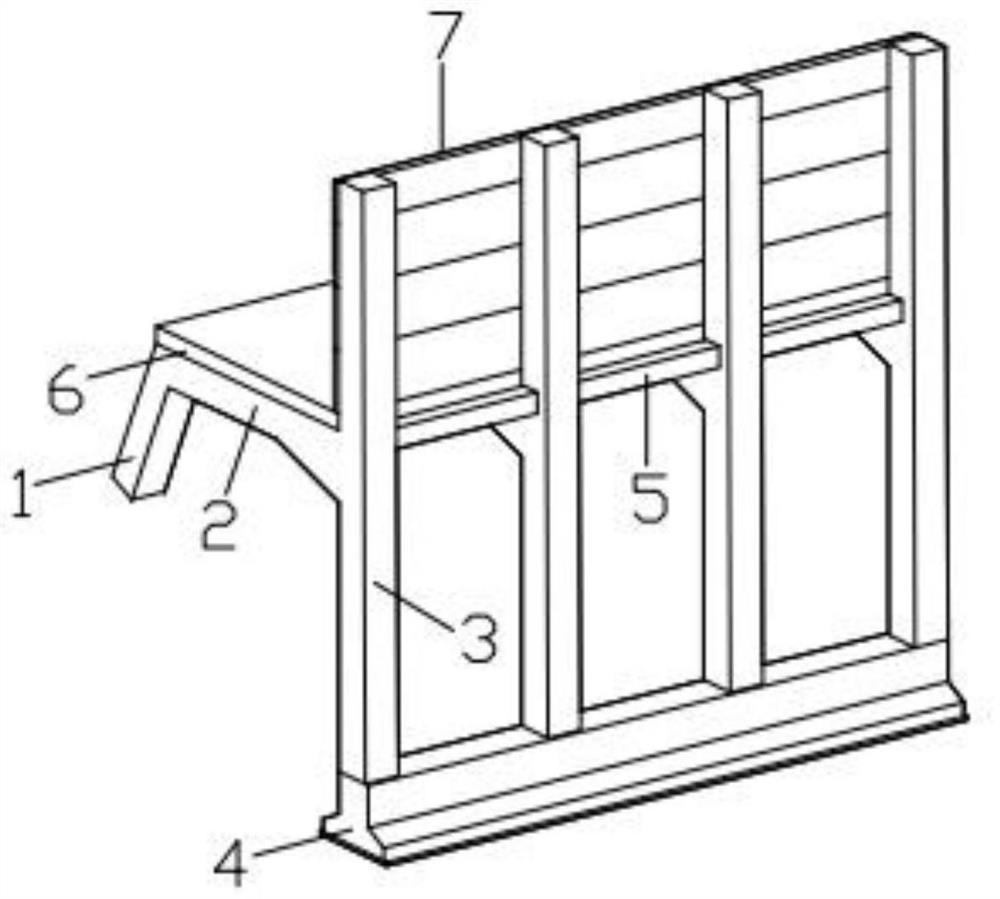

[0030] see figure 1 , a steep slope high-fill subgrade structure using high-density EPS filler, including short piles 1, beams 2, columns 3, enlarged foundations 4, longitudinal tie beams 5, bearing plates 6, retaining plates 7, lightweight fillers 8, Sand cushion 9, road slab 10, crash barrier 11 and gutter 12.

[0031] During construction, adopt manual operation method to excavate the pile holes of the longitudinal short pile 1, lower the reinforcement cage, formwork support, and pour concrete; excavate and pour the enlarged foundation 4, and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com