Pipe and pond combined type gleaming bioreactor system and microalgae growth carbon consolidating method

A bioreactor and reactor technology, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of flow resistance reducing the flow speed of algae liquid, etc. Achieve the effect of strengthening the flash effect, improving the distribution of the projection area, and alleviating the light suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

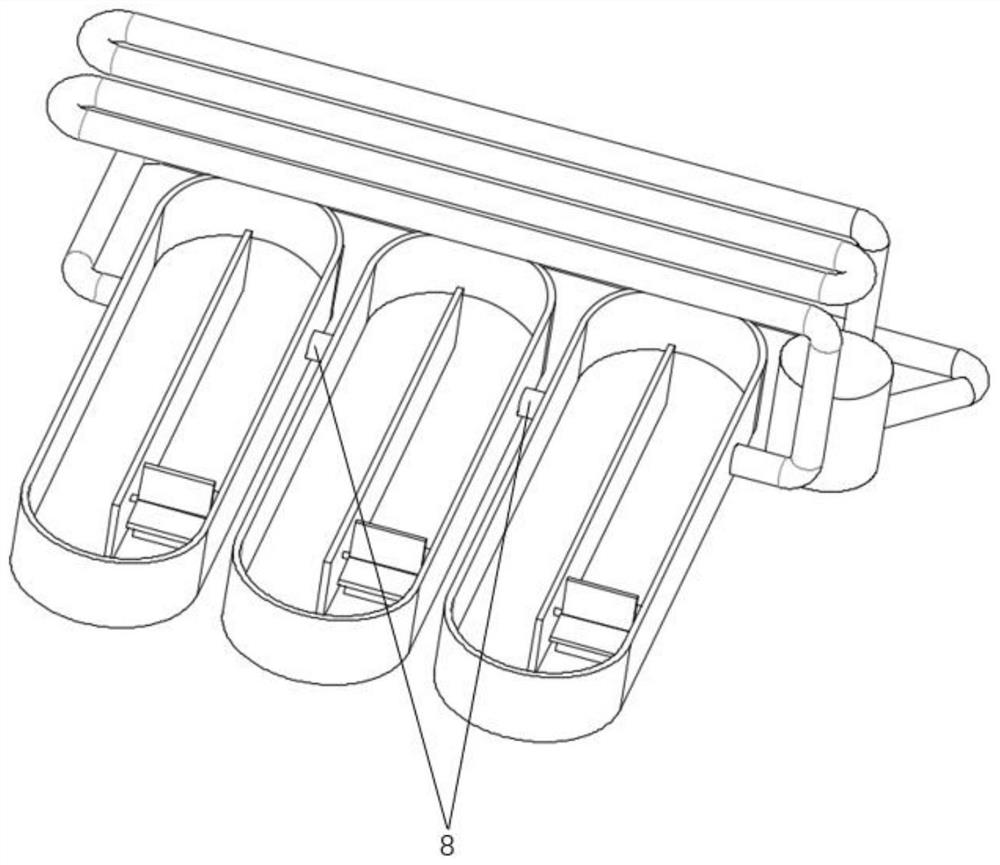

[0035] The tube pool combined flash bioreactor system is composed of the upper horizontal horizontal tube and the lower runway pool, and the horizontal horizontal tube and the runway pool present a cross shape. Arrange 10 rows of horizontal transverse tubes above the length direction of the runway pool, and arrange 3 runway pools below the length direction of the horizontal transverse tubes. The distance between the bottom of the horizontal cross pipe and the bottom of the runway pool is 2 meters. The upper horizontal horizontal tube adopts vertical stacking to form a multi-layer horizontal tube structure, and its tube diameter is 5 cm, and the material is all light-transmitting tubes (that is, polymer tubes with a light transmittance of more than 80%). The total number of layers of horizontal horizontal tubes is 1 layer, and the distance between the walls of two adjacent tubes in the horizontal direction is 10 times the diameter of the tubes. The upper horizontal horizontal ...

Embodiment 2

[0039] The tube pool combined flash bioreactor system is composed of the upper horizontal tube and the lower runway pool, and the horizontal horizontal tube and the runway pool present a cross shape. Arrange 300 rows of horizontal transverse tubes above the length direction of the runway pool, and arrange 6 runway pools below the length direction of the horizontal transverse tubes. The distance between the bottom of the horizontal cross pipe and the bottom of the runway pool is 2 meters. The upper horizontal horizontal tubes are vertically stacked to form a multi-layer horizontal tube structure with a diameter of 5 cm and made of light-transmitting tubes (that is, ordinary glass with a light transmittance of more than 80%). The total number of layers of horizontal horizontal pipes is 2 layers, the distance between the pipe walls of two adjacent pipes in the vertical direction is 1 times the diameter of the pipe, and the distance between the pipe walls of two adjacent pipes in ...

Embodiment 3

[0043] The tube pool combined flash bioreactor system is composed of the upper horizontal tube and the lower runway pool, and the horizontal horizontal tube and the runway pool present a cross shape. Arrange 1000 rows of horizontal transverse tubes above the length direction of the runway pool, and arrange 10 runway pools below the length direction of the horizontal transverse tubes. The distance between the bottom of the horizontal cross pipe and the bottom of the runway pool is 2 meters. The upper horizontal horizontal pipe adopts vertical stacking to form a multi-layer horizontal pipe structure, the diameter of which is 5 cm, and the material is light-transmitting pipe (that is, tempered glass with a light transmittance of more than 80%). The total number of layers of horizontal horizontal pipes is 5 layers, the distance between the pipe walls of two adjacent pipes in the vertical direction is 5 times of the pipe diameter, and the distance between the pipe walls of two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com