A kind of laundry beads with 8 times cleaning power and preparation method thereof

A laundry condensation and cleaning technology, which is applied in the field of daily chemical detergents, can solve the problem that the cleaning power of three kinds of stains cannot reach 8 times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

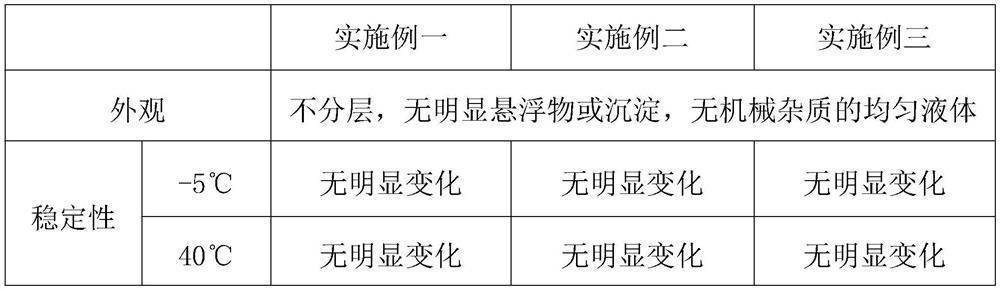

Examples

Embodiment 1

[0027] 8 having a cleaning power of washing times condensate bead, mass percentages of components comprising:

[0028] 8% dodecylbenzene sulfonic acid, polyoxyethylene fatty alcohol ether sulfate 20%, fatty acid methyl ester ethoxylates (Japan Synthetic Chemical Co., Ltd.) 23%, isomeric ten polyoxyethylene ethers ( BASF Lutensol XL-80) 8%, fatty alcohol polyoxyethylene ether AEO-9 (Kao KAO EMULGEN 109) 6%, 18% propylene glycol, triethanolamine 6%, N, N- trisodium dicarboxymethyl-alanine ( Akzo Nobel Dissolvine M-40) 0.5%, hydrophobically-modified acrylic polymer (Dow Acusol 845) 3%, protease (Novozymes progress Uno100L) 1.6%, 2% propionate, within 1% DMDM hydantoin, daily flavor 2.9%.

[0029] A method of preparing 8-fold laundry cleaning power beads having a condensate, comprising the steps of:

[0030] (1) in mass percent, weighing each raw material;

[0031] (2) propylene glycol was added to the kettle and heated to 55 ℃, dodecylbenzenesulfonic acid was then added, followed b...

Embodiment 2

[0034] 8 having a cleaning power of washing times condensate bead, mass percentages of components comprising:

[0035] 15% dodecylbenzenesulfonic acid, polyoxyethylene fatty alcohol ether sulfate 16%, fatty acid methyl ester ethoxylate 18%, isomeric ten polyoxyethylene ether (BASF Lutensol XL-80) 6%, fat alcohol polyoxyethylene ether AEO-9 (Kao KAO EMULGEN 109) 17%, 11% glycerol, triethanolamine 11%, N, N- trisodium dicarboxymethyl-alanine (Akzo Nobel Dissolvine M-40) 3% styrene - acrylic copolymer hydrophobically modified (Wanhua chemical Group Co., Ltd., model Unicap K25A) 0.5%, protease (BASF lavergy pro 104LS) 0.8%, propionate 0.5%, DMDM hydantoin 0.4% , daily flavor 0.8%.

[0036] A method of preparing 8 times cleanliness, including the following steps:

[0037] (1) Tell all raw materials according to the percentage of quality;

[0038] (2) Glycerol is added to the reaction kettle, warmed to 60 ° C, then dodecyl benzenesulfonic acid, then slowly add triethanolamine and mixed ...

Embodiment 3

[0041] A laundry with 8 times cleanliness, including the following mass percent components:

[0042] Dodecyl benzenesulfonic acid 19%, sodium fatty alcohol polyoxyethylene ether sulfate, 5% ethoxylated fatty acid methyl ester ethoxylate, isomergol polyoxyethylene ether (BASF LUTENSOL XL-80) 11%, fat Alcohol polyoxyethylene ether Aeo-9 (Flower Kao Emulgen 109) 10%, sorbitol 15%, triethanolamine 15%, N, N-dikarboxymethyl aproxine trisodium (Akuso Bell Dissolvine M-40) 5 %, Hydrophobic modified acrylic polymer (Dow Acusol 845) 1.5%, protease (Novictive Progress UNO100L) 2.4%, Casson 1%, DMDM Ethyl urea 1.5%, daily flavor 1.6%.

[0043] A method of preparing 8 times cleanliness, including the following steps:

[0044] (1) Tell all raw materials according to the percentage of quality;

[0045] (2) Add sorbitol to the reactor, warmed to 65 ° C, then add dodecyl benzenesulfonic acid, then slowly add triethanolamine, and mixed with fat alcohol polyoxyethylene ether sodium sulfate after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com