A kind of mortar using thermal power plant solid waste light aggregate as raw material, a method for preparing mortar and a prefabricated component prepared

A technology for thermal power plants and light aggregates, applied in the field of building materials, can solve the problems of poor water resistance, affect product performance, low strength, etc., and achieve the effects of promoting alkaline excitation reaction, reducing process treatment costs, and reducing pollution emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A mortar using solid waste light aggregates from thermal power plants as raw materials, the mortar comprises the following raw materials in parts by weight on a dry basis: 10 parts of α-desulfurized gypsum (initial setting time is 5 minutes), β-desulfurization gypsum (initial setting time is 3 minutes) 15 parts, 20 parts of modified components, and 0.8 parts of admixtures;

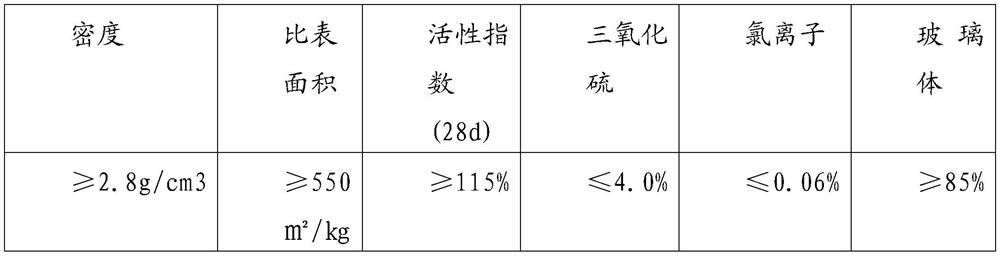

[0058] Wherein, the modified component includes the following raw materials on a dry basis: slag (specific surface area 600㎡ / kg; density of the slag 2.85g / cm 3 ; the activity index of the slag is 118%) 70 parts, quicklime 8 parts, micro-silica powder (silicon dioxide content 96%; the fineness of the micro-silica powder is ≤ 0.8μm in the weight ratio of the micro-silica powder 85%) 6 parts, calcium stearate 4 parts;

[0059] The admixture includes the following raw materials in parts by weight on a dry basis: 1.5 parts of hydroxypropyl methyl cellulose ether, 5 parts of calcium bentonite, 3.5 parts...

Embodiment 2

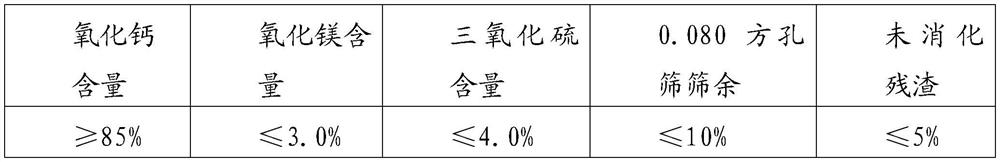

[0061] A mortar using solid waste light aggregates from thermal power plants as raw materials, the mortar comprises the following raw materials in parts by weight on a dry basis: 12 parts of α-desulfurized gypsum (initial setting time is 5 minutes), β-desulfurization gypsum (initial setting time is 3 minutes) 42 parts, fly ash (free calcium oxide 2.8%) 22 parts, bottom slag secondary mixture (chloride ion content 200mg / kg; the particle size of the bottom slag secondary mixture is 3-5mm) 18 parts , 22 parts of modified components, 0.8 parts of admixtures;

[0062] Wherein, the modified component includes the following raw materials by weight on a dry basis: slag (specific surface area: 560 m2 / kg; density of the slag: 2.8 g / cm) 3 ; the activity index of the slag is 116%) 72 parts, quicklime 9 parts, micro-silica powder (silicon dioxide content 95%; the fineness of the micro-silica powder is ≤ 0.8μm in the weight ratio of the micro-silica powder 82%) 3~10 parts, calcium stearate...

Embodiment 3

[0065] A kind of mortar using the solid waste light aggregates of thermal power plants as raw materials, the mortar comprises the following raw materials in parts by weight on a dry basis: 8 parts of α-desulfurized gypsum (initial setting time is 5min), β-desulfurization gypsum (initial setting time is 3min) 38 parts, fly ash (free calcium oxide 2.9%) 18 parts, bottom slag secondary mixture (chloride ion content 200mg / kg; the particle size of the bottom slag secondary mixture is 3-5mm) 12 parts , 18 parts of modified components, 0.6 parts of admixtures;

[0066] Wherein, the modified component includes the following raw materials by weight on a dry basis: slag (specific surface area 555㎡ / ㎏; density of the slag 2.85g / cm 3 ; the activity index of the slag is 117%) 68 parts, quicklime 6 parts, micro-silica powder (silicon dioxide content 95.5%; the fineness of the micro-silica powder is ≤ 0.8μm in the weight ratio of the micro-silica powder 80% or more) 4 parts, 3 parts of calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com