Suspension carrier module, sewage treatment tower and sewage treatment method

A technology of sewage treatment and carrier, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc. Stability and other issues, to achieve the effect of improving sewage treatment efficiency, convenient and fast on-site assembly, and improving surface utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

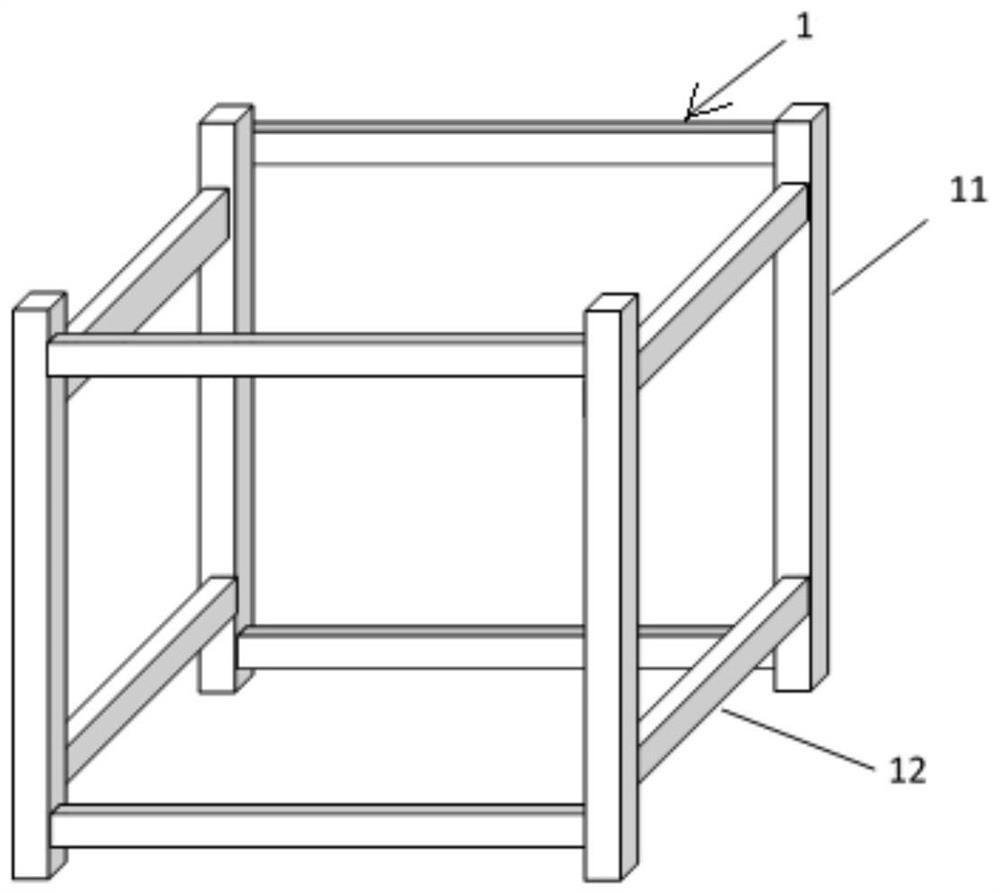

[0067] In some embodiments, the manufacture of the suspension carrier module provided by the present application adopts the following four steps:

[0068] step one

[0069] Four 50mm×50mm stainless steel square tubes with a length of 1000mm are used as the four vertical columns 11 of the module frame 1, where mm represents the length unit: mm, and eight 40mm×40mm stainless steel square tubes with a length of 1000mm are used as the four vertical columns 11 of the module frame 1 The connecting rods 12 between the four vertical columns 11 connect the four vertical columns 11 and the eight connecting rods 12 by welding or screwing to form a complete hollow three-dimensional frame structure to obtain the module frame 1 .

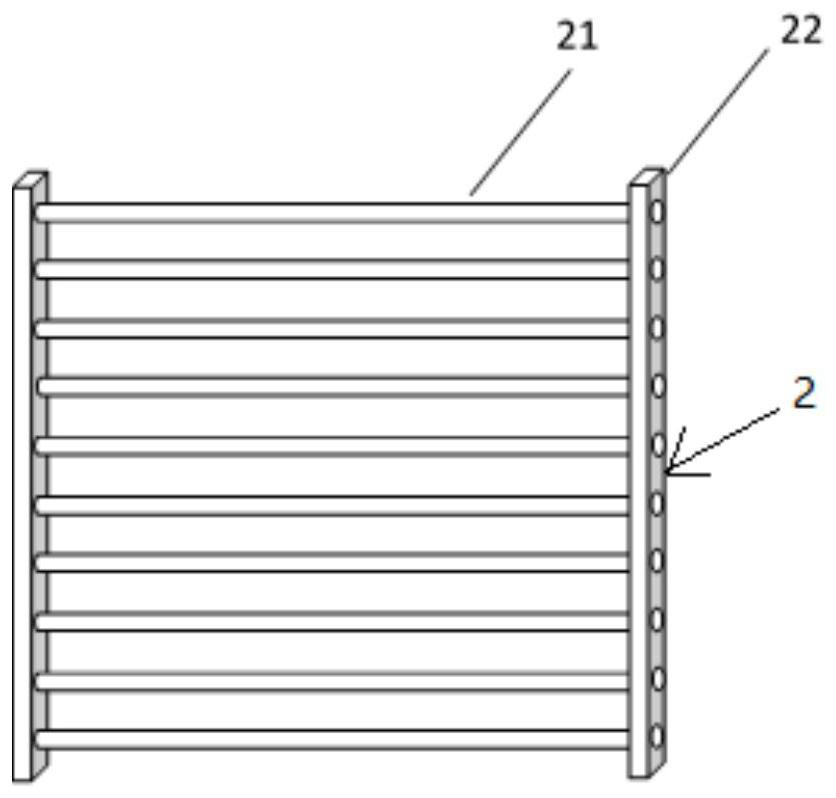

[0070] step two

[0071] Two 40mm×40mm stainless steel square tubes with a length of 1000mm are used as the slats 22 of the rectangular frame of the carrier grid 2, and 10 round holes with a diameter of 20mm are evenly opened on them, and 10 stainless steel pipe...

Embodiment 2

[0077] In some embodiments, the fabrication of the sewage treatment tower can adopt the following steps:

[0078] step one

[0079] Make a sump 6 with a length of 2.2m, a width of 2.2m, and a depth of 0.6m with concrete; wherein, m represents the unit of length: meter, on the pool wall on one side of the sump 6, the height of 0.4m from the bottom of the sump 6 Water outlet pipes are set at the four corners of the sump 6, the midpoints of the four sides, and the center of the sump 6. Nine pillars 62 with a height of 0.6m are set as the basic fulcrums for suspending the carrier module; Four tower columns with a height of 4.5m are built on the outside of the corners. At the top and middle of the tower columns, beams are used to connect the adjacent tower columns along the direction of the six sides of the sump to form a frame to maintain stability.

[0080] step two

[0081]Arrange the four suspended carrier modules prepared in Example 1 in a square, place and fix them on the f...

Embodiment 3

[0088] In Embodiment 2, a centrifugal pump is installed outside the sump 6 as the water pump 7, and a plastic pipe is connected to the inlet of the water pump 7 and connected to the sump 6 below the water surface. The outlet pipe of the water pump 7 is provided with a flow meter and a regulating valve, and is connected to the water distribution device 51 through a tee.

[0089] In this embodiment, a sewage treatment tower capable of returning the water in the sump 6 is obtained, which can be used in sewage treatment projects requiring high total nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com