A system for preparing feed-grade phosphoric acid by wet-process phosphoric acid and its preparation method

A wet-process phosphoric acid, feed-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low defluorination efficiency, high cost of liquid-solid separation, large loss of phosphorus, etc., to improve the yield of phosphorus , to avoid the effect of excessive phosphoric acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

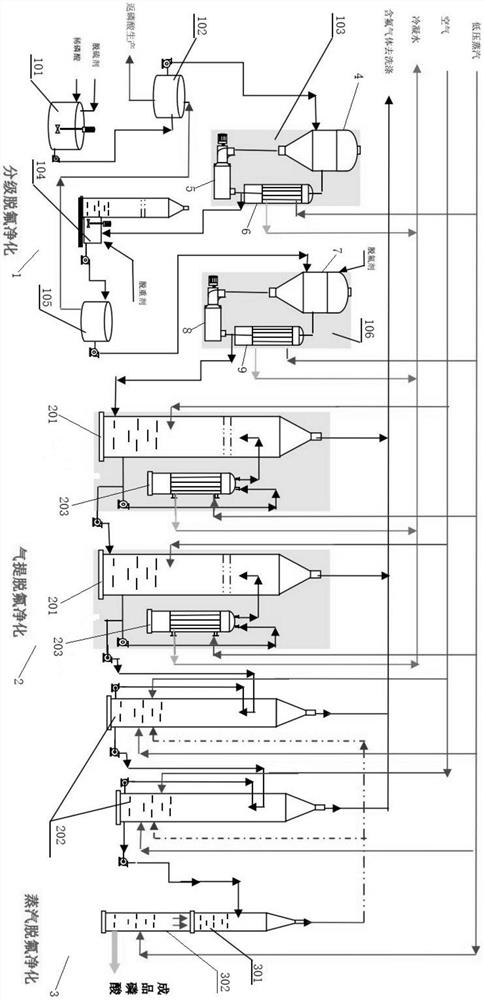

[0034] figure 1 It shows: a system for preparing feed-grade phosphoric acid from wet-process phosphoric acid, which is composed of a graded concentration defluorination section 1, a gas stripping defluorination section 2, and a steam defluorination section 3.

[0035] The fractional concentration and defluorination section 1 is composed of a dilute acid aging tank 101, a dilute acid settling tank 102, a primary concentration unit 103, a weight removal reaction tank 104, an intermediate acid settling tank 105, and a secondary concentration unit 106, which are connected in sequence. Composition, the outlet at the bottom of the intermediate acid settling tank 105 is connected to the inlet of the dilute acid settling tank 102, the outlet at the bottom of the dilute acid settling tank 102 is connected to the phosphoric acid production device, and the inlet of the dilute acid aging tank 101 is connected to the phosphoric acid production device.

[0036] The primary concentration uni...

Embodiment 2

[0040] A preparation method for wet process phosphoric acid to prepare feed grade phosphoric acid, specifically comprising the steps of:

[0041] (1) Fractional concentration and defluorination purification:

[0042] 1-1. Pump the dilute phosphoric acid obtained in the production of wet-process phosphoric acid into the dilute acid aging tank 101, and add a desulfurizing agent to remove sulfate radicals; the desulfurizing agent is phosphate rock slurry with a grade of 30% and containing The solid content is 60%, and the addition amount of phosphate rock is controlled by 1.0 times of the theoretically calculated amount.

[0043] 1-2. Pump the desulfurized dilute phosphoric acid into the dilute acid settling tank 102 for clarification to obtain P 2 o 5 Concentration of 25%, F content of 2.2% of the upper cleaning acid, dilute acid sedimentation tank 102 bottom slag acid is returned to the phosphoric acid production device, the upper cleaning acid is pumped into the primary conc...

Embodiment 3

[0052] A preparation method for wet process phosphoric acid to prepare feed grade phosphoric acid, specifically comprising the steps of:

[0053] (1) Fractional concentration and purification:

[0054] 1-1. Pump the dilute phosphoric acid obtained in the production of wet-process phosphoric acid into the dilute acid aging tank 101, and add a desulfurizer to remove sulfate radicals; the desulfurizer is phosphate rock pulp, the grade of which is 32%, and the The amount is 63%, and the addition amount of phosphate rock is controlled by 1.1 times of the theoretically calculated amount.

[0055] 1-2. Pump the desulfurized dilute phosphoric acid into the dilute acid settling tank 102 for clarification to obtain P 2 o 5 Concentration of 26%, F content of 2.5% of the upper cleaning acid, dilute acid settling tank 102 bottom slag acid is returned to the phosphoric acid production device, the upper cleaning acid is pumped into the primary concentration unit 103 for concentration;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com