Auxiliary Die for Grading and Slow Cooling Layer Casting

A mold and slow cooling technology, applied in the field of grading slow cooling layer casting auxiliary mold, can solve the problems of increasing production area, high cooling cost, high cost, etc., to increase the water vapor receiving area and increase the residence time. , the effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

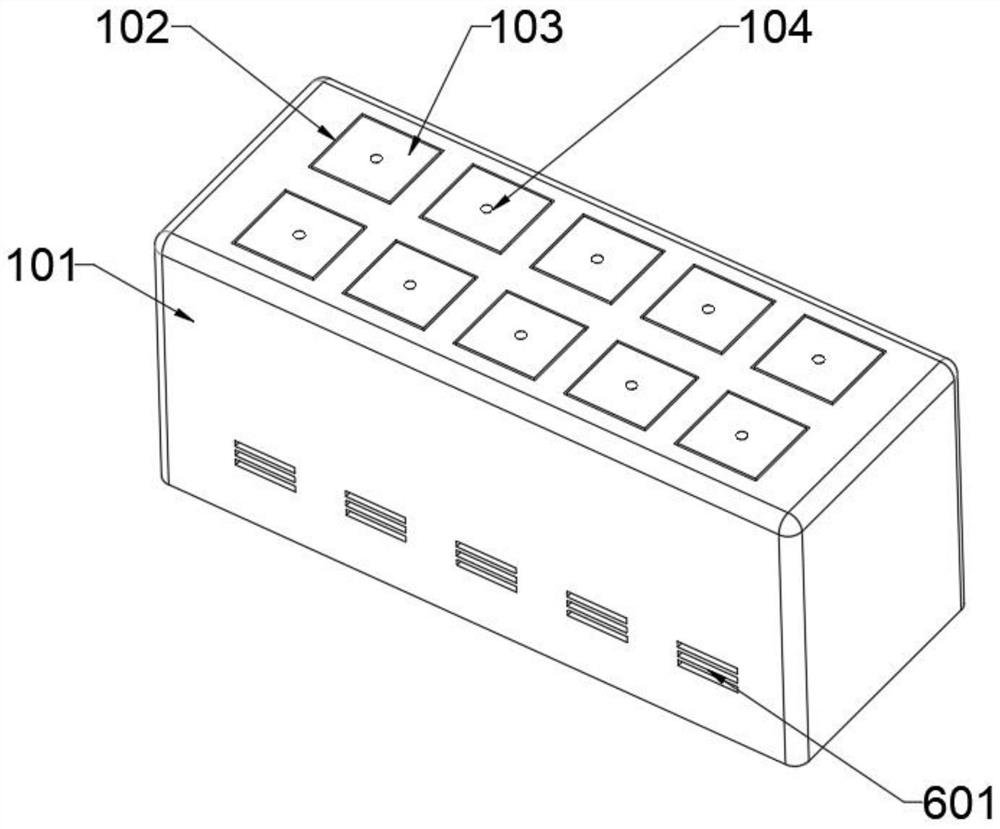

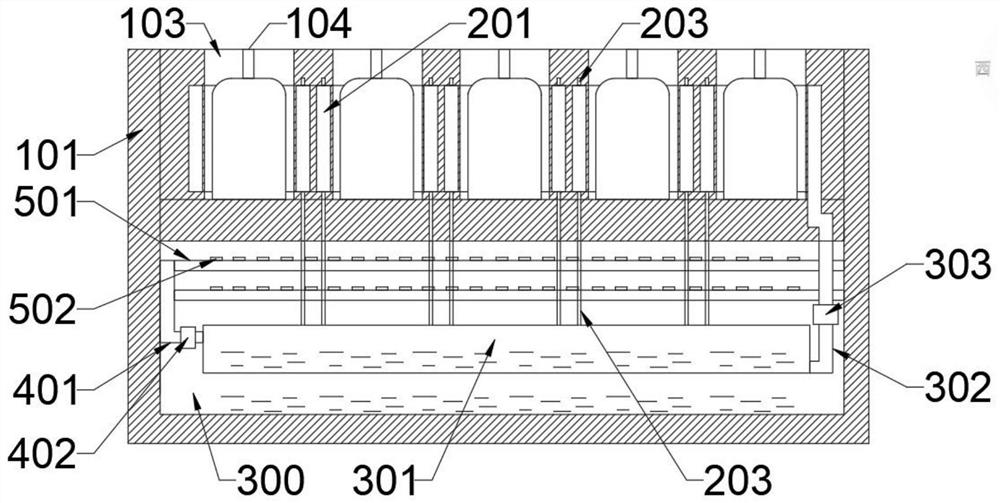

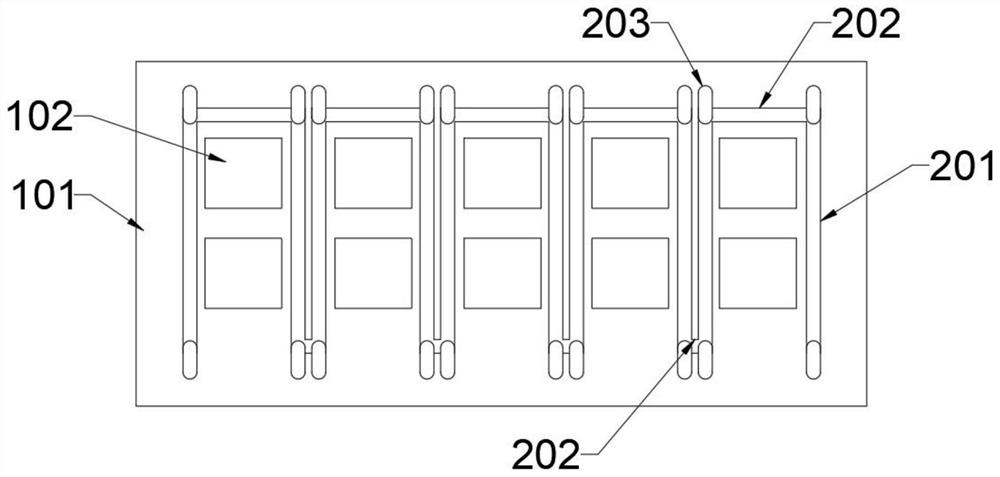

[0027] Example: such as Figure 1-5 As shown, the graded slow-cooling layer casting auxiliary mold includes support components, heat exchange components, water delivery components, pressure relief components, steam dissipation components, and auxiliary components. The function of the components, the top of the support assembly is equipped with a heat exchange assembly, which plays the role of heat exchange and cooling of the mold, and the bottom of the support assembly is provided with a water delivery assembly, which plays the role of delivering water to the heat exchange assembly. There is a pressure relief component on the side of the water delivery component, which can adjust the pressure. One end of the pressure relief component is equipped with a steam diffuser component, which plays the role of dispersing water vapor. The supporting component is equipped with an auxiliary Components and auxiliary components play a role in enhancing the cooling effect of water vapor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com