Dye stirring, stirring and mixing device for textile processing

A technology of stirring and mixing dyes, applied in the directions of shaking/oscillating/vibrating mixers, mixers, mixing methods, etc., can solve the problems of poor mixing effect and the inability of dyes to contact each other, and achieve increased mixing effect, simple structure and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

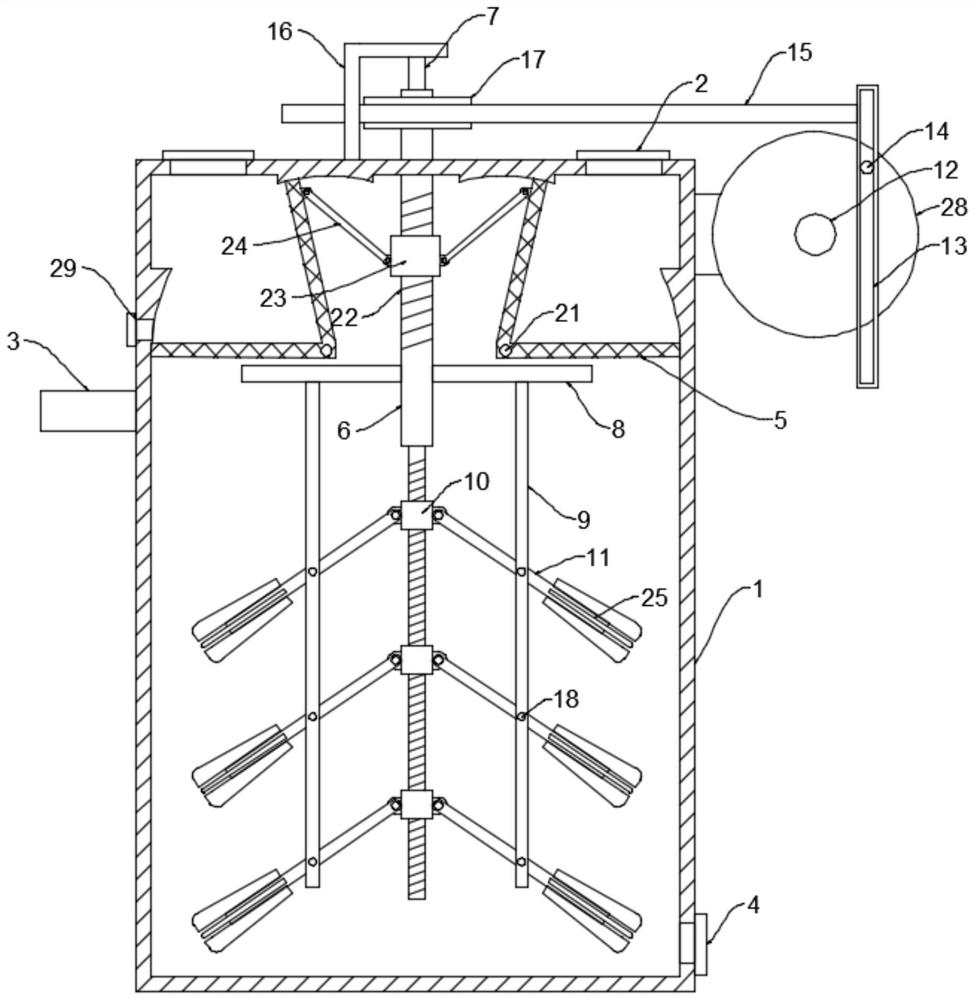

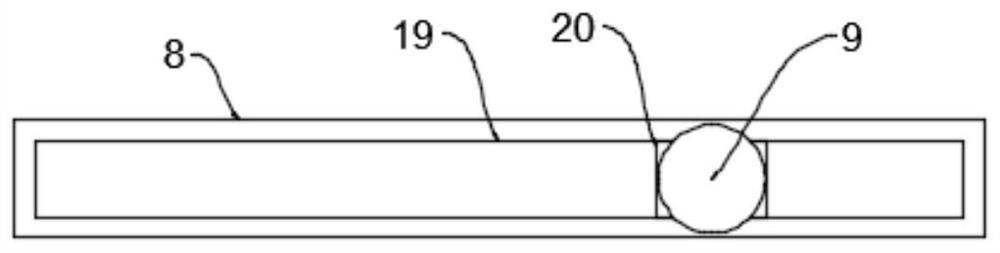

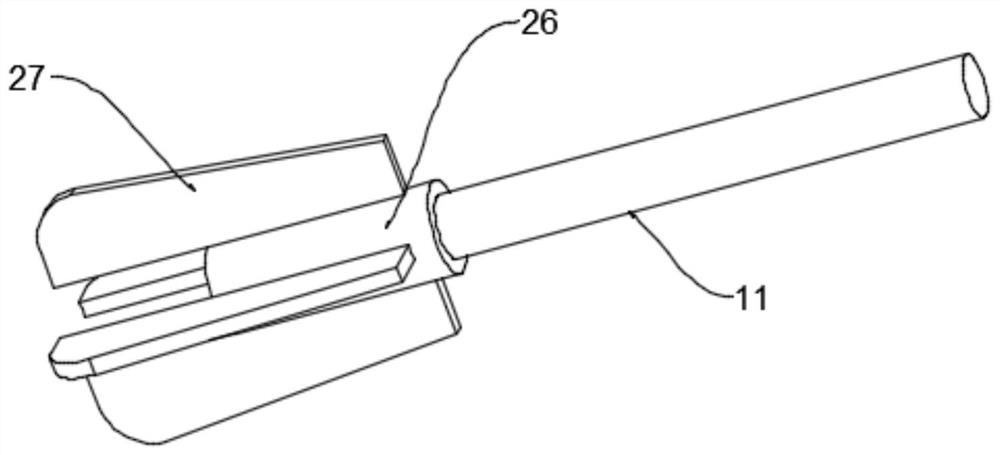

Embodiment 1

[0022] see Figure 1~3 , in the embodiment of the present invention, a stirring and mixing device for dyestuffs for textile processing, comprising a mixing box 1 and a stirring mechanism arranged inside the mixing box 1, two inlets are provided on the top wall of the mixing box 1. The material port 2 and the side wall of the mixing box 1 are provided with a liquid inlet pipe 3. The stirring mechanism includes a rotating sleeve 6, a fixed screw 7, a plurality of stirring components and a driving component, and the top of the fixed screw 7 is rotated and installed. In the center of the top wall of the mixing box 1 and driven by the drive assembly to rotate forward and reverse, the fixed screw rod 7 is installed inside the rotating sleeve 6 and is rotatably matched, and the top of the rotating sleeve 6 is connected to the top of the mixing box 1 through the fixing frame 16 The wall is fixedly connected, and the agitation assembly includes a cross bar 8, a vertical bar 9 and a swi...

Embodiment 2

[0027] The difference between the embodiment of the present invention and embodiment 1 is that: the inside of the mixing box 1 is also provided with a filter screen frame 5 located at the feed port 2, and the filter screen frame 5 and the inner wall of the mixing box 1 form a filter In the chamber, the powder poured into the feed port 2 can be filtered through the filter screen frame 5 to remove the particles, which can improve the quality of the dye. The inner wall of body 1 is sealed and slid;

[0028] The corners of the filter screen frame 5 are rotationally connected with the inner wall of the mixing box 1 through the fixed rod shaft 21, and the outer wall of the rotating sleeve 6 is provided with a helical section 22, and the helical section 22 is provided with a second driving screw sleeve 23 matched therewith. , the second driving screw sleeve 23 sides are provided with a push-pull rod 24 with one end hinged to its side wall, and the other end of the push-pull rod 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com