Multi-material full-automatic mixing device for SV type cleaning equipment and control system thereof

A technology of mixing device and control system, which is applied in the field of multi-material automatic mixing device for SV type cleaning equipment and its control system, can solve the problems of cumbersome process, waste of raw materials, easy generation of liquid accumulation, etc. The ratio is more accurate, the cleaning effect is improved, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

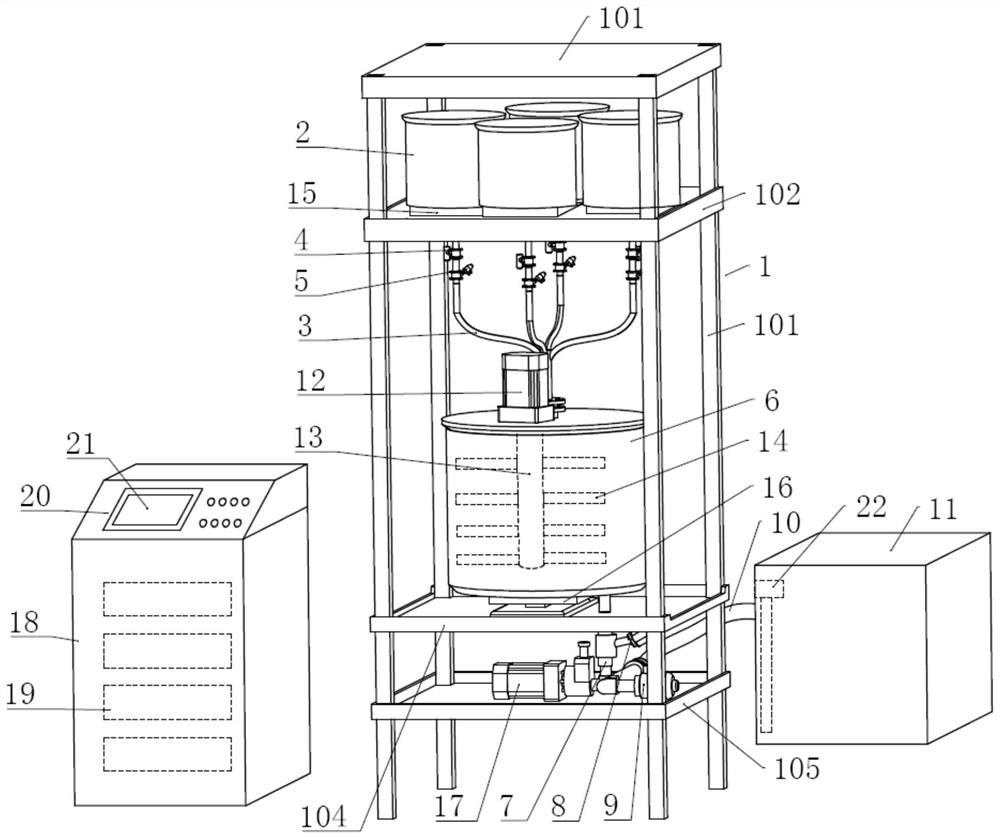

[0036] In this example, combined with figure 1As shown, a multi-material automatic mixing device for SV-type cleaning equipment includes a frame 1, a number of material bins 2 are arranged on the top of the frame 1, and conveying pipes 3 are connected to the bottom of the number of material bins 2. The conveying pipe 3 can transport the raw materials in the material bin 2 to the mixing tank 6 for mixing. In this embodiment, there are four material bins 2, and four kinds of materials can be mixed at most. The conveying pipe 3 is equipped with The first wireless flowmeter 4 and the first solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com