Continuous multi-channel adsorption equipment and industrial waste gas treatment system

A technology for adsorption equipment and industrial waste gas, which is applied in gas treatment, membrane technology, and separation of dispersed particles. It can solve the problems of easy clogging, moldy, high cost of industrial waste gas treatment, and frequent replacement of adsorption materials. , Reduce operating costs, save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

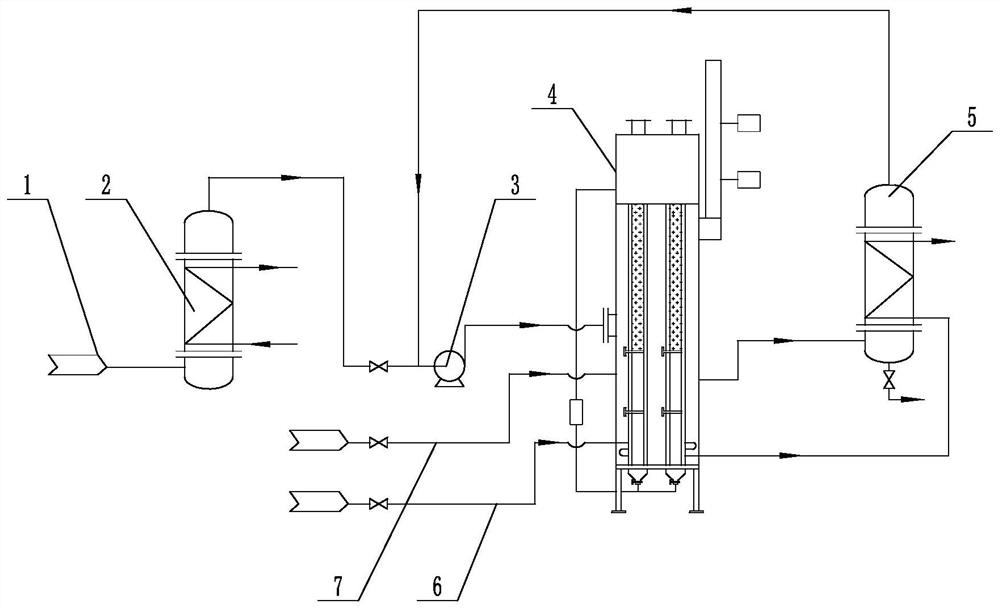

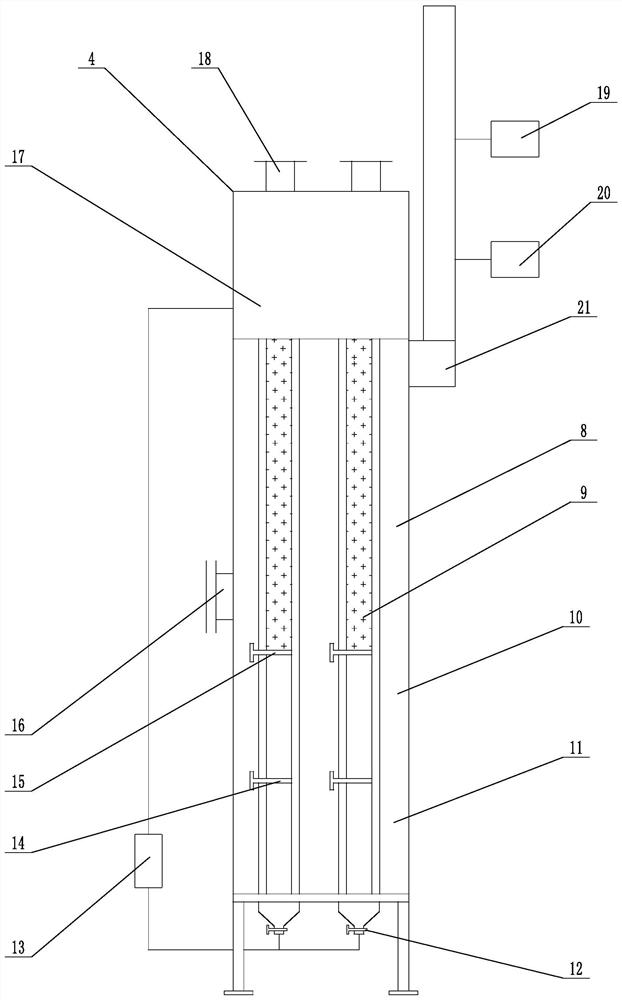

[0030] Such as Figure 1-2 As shown, in the continuous multi-channel adsorption equipment, the adsorption equipment 4 is divided into an adsorption chamber 8, a desorption chamber 10, and a cooling chamber 11 from top to bottom, and the upper part of the adsorption chamber 8 is provided with a temporary storage chamber 17 , the bottom of the adsorption chamber 8 is provided with an air inlet 16, the top of the adsorption chamber 8 is provided with an air outlet 21, and the adsorption device 4 is provided with two adsorption channels 9, the adsorption channels 9 run through the adsorption chamber 8, desorption Chamber 10 and cooling chamber 11 , the upper inlet of the adsorption channel 9 communicates with the temporary storage chamber 17 , and the lower outlet of the adsorption channel 9 connects with the temporary storage chamber 17 through the lifting device 13 .

[0031] The adsorption passage 9 between the adsorption chamber 8 and the desorption chamber 10 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com