Battery device capable of real-time monitoring of electrode stress changes, battery using the device, and application of the device

A technology of stress change and real-time monitoring, which is applied in secondary batteries, electrochemical generators, and measurement of the properties and forces of piezoresistive materials, etc. problem, to achieve the effect of great practical significance, simple operation, simple and efficient characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

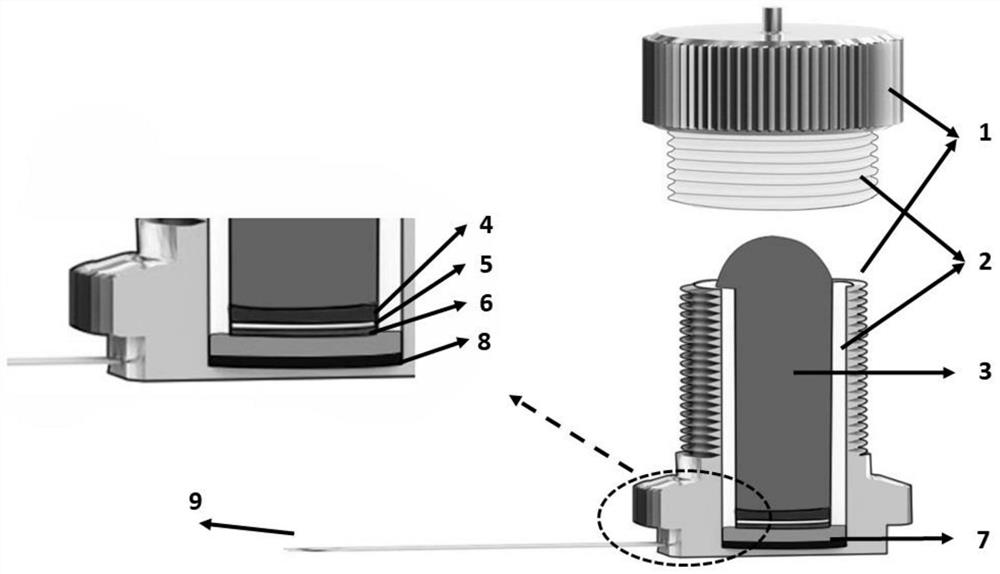

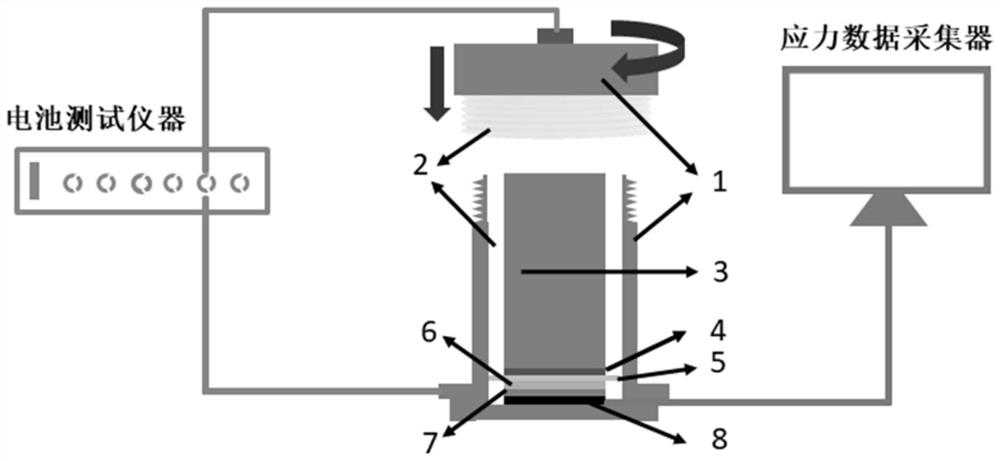

[0038] reference figure 1 A battery device that can monitor electrode stress in real time, including:

[0039]The metal housing 1 is composed of an upper metal casing and a lower metal casing. In the present embodiment, the upper metal casing of the metal casing 1 is a positive electrode shell, and the lower metal casing is a negative electrode shell. When the opposite polarity is taken, the polarity of the remainder is The same opposite process can be processed. The longitudinal inner wall of the upper metal casing has an inner thread, and the longitudinal outer wall of the lower metal housing has an external thread.

[0040] The hollow cylindrical insulating member 2 is composed of an upper insulating hollow cylinder and a lower insulating hollow cylinder. The longitudinal inner and outer walls of the upper insulating hollow cylinder are respectively threaded and outer threads, and the upper insulating hollow cylinder is an insulating connection. The thread is connected to the i...

Embodiment 2

[0050] Basic structure is as in the case of the embodiment, the preparation process:

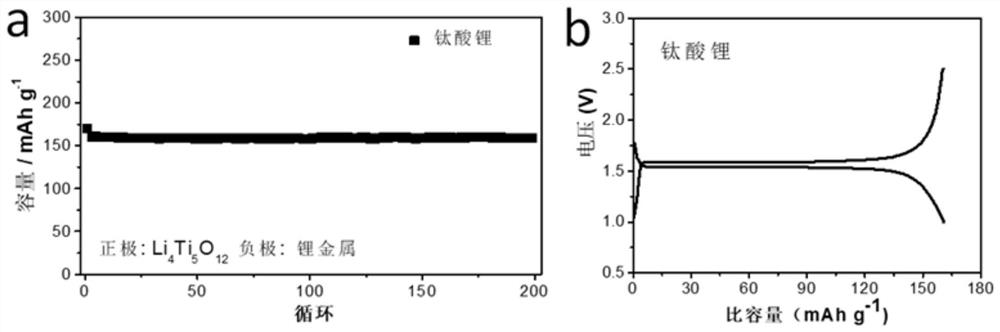

[0051] According to the bottom first, the metal gasket 7 is placed on the surface of the film pressure sensor 8, which is then used to connect the metal gasket and the negative electrode shell using a wire. The negative electrode sheet 6 is placed on the surface of the spacer, and the negative electrode sheet 6 uses a metal lithium foil, and then the diaphragm CelGard 2400 and the positive electrode plate 4 (lithium titanate slurry are coated on the aluminum foil current). Choose 1 mol / L Li PF 6 EC: DEC (volume ratio is 1: 1) mixed solution organic electrolyte, and add an appropriate amount to the electrode and the diaphragm. Thereafter, the lower insulating hollow cylinder is placed in the negative electrode shell, and the metal solid cylinder 3 is inserted into the lower insulating hollow cylinder, pressed on the positive electrode plate 4. Finally, the upper insulating hollow cylinder and t...

Embodiment 3

[0055] Basic structure is as in the case of the embodiment, the preparation process:

[0056] According to the bottom first, the metal gasket 7 is placed on the surface of the film pressure sensor 8, which is then used to connect the metal gasket and the negative electrode shell using a wire. The negative electrode sheet 6 is placed on the surface of the gasket (the active negative electrode material silicone slurry is dispersed in the copper set fluid surface), and then put the middle member 5 (diaphragm CelGard 2400) and positive electrode plate 4 (lithium iron phosphate slurry is coated) Aluminum foil agglomerates). Choose 1 mol / L Li PF 6 EC: DEC (volume ratio is 1: 1) mixed solution organic electrolyte, and add an appropriate amount to the electrode and the diaphragm. Thereafter, the lower insulating hollow cylinder is placed in the negative electrode shell, and the metal solid cylinder 3 is inserted into the lower insulating hollow cylinder, pressed on the positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com