Cable insulation layer shrinkage processing device and process

The technology of a cable insulation, processing device, is used in the direction of using conductive/cable insulation, cable/conductive manufacturing, circuit and other directions. The effect of envelope effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

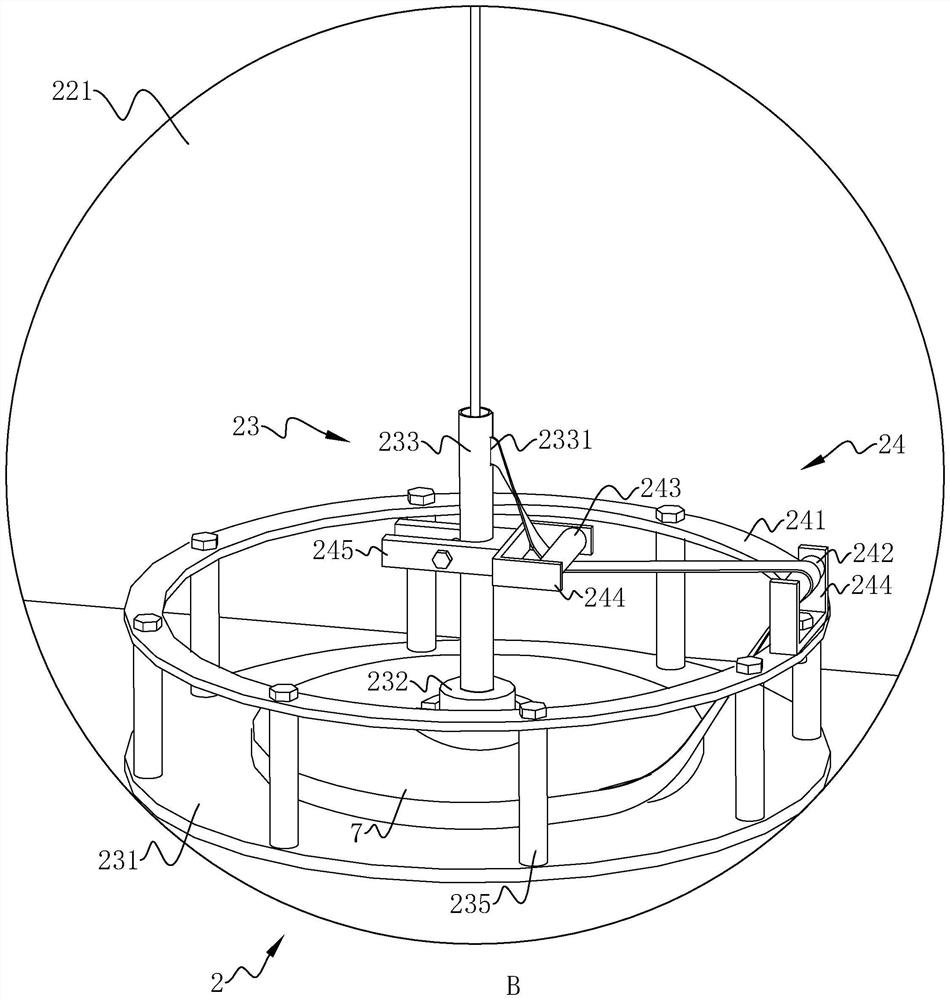

[0047] The application will be described in further detail below in conjunction with the accompanying drawings.

[0048] Such as figure 1 As shown, it is a cable insulation layer shrinkage processing device disclosed in the present application, which includes a wire supply mechanism 1 , a coating mechanism 2 and a winding mechanism 3 .

[0049] Such as figure 1 and figure 2 As shown, the wire supply mechanism 1 includes a frame body 11, a mounting structure and an adjustment structure. The frame body 11 includes a side plate 111, a top rod 112 and a bottom rod 113. Two side plates 111 are arranged in parallel, which are used for the entire frame body 11 support, the top rod 112 and the bottom rod 113 are all arranged between the two side plates 111, the two ends of the top rod 112 are respectively welded to the positions near the top of the two side plates 111, and the two ends of the bottom rod 113 are respectively welded At the position where the two side panels 111 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com