Outer diameter measuring device and method for thin-wall bearing ring

A thin-walled bearing and measuring device technology, applied in measuring device, mechanical measuring device, mechanical diameter measurement, etc., can solve problems such as force measurement error, measuring head not pointing to bearing ring, eccentricity error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

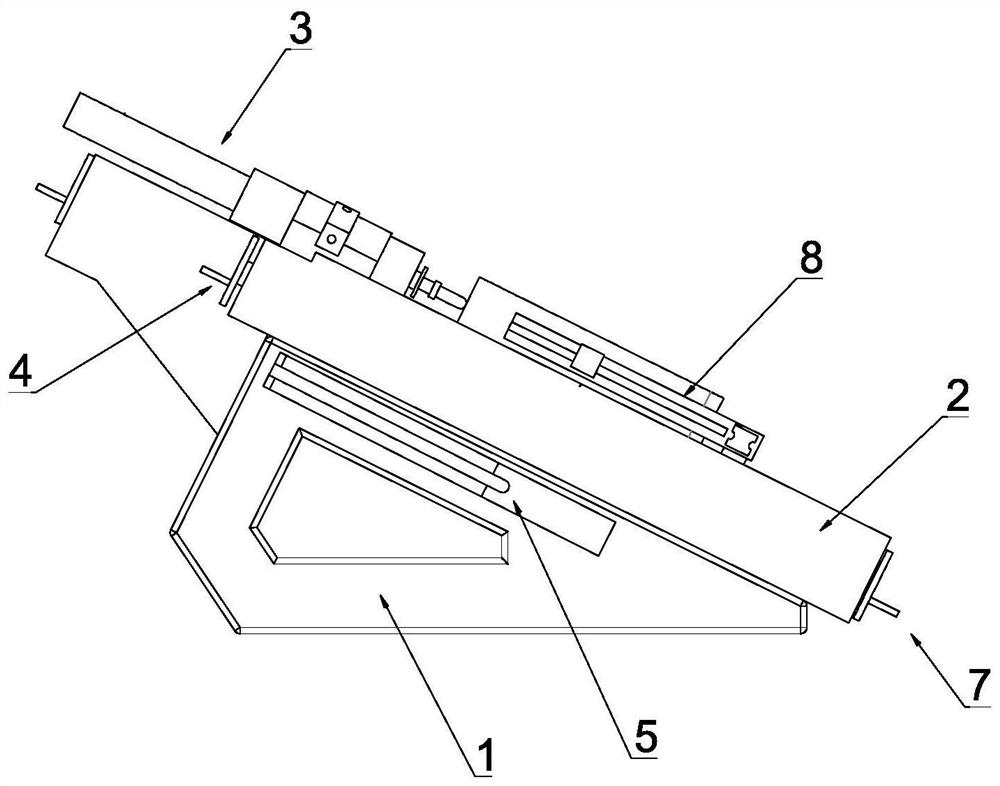

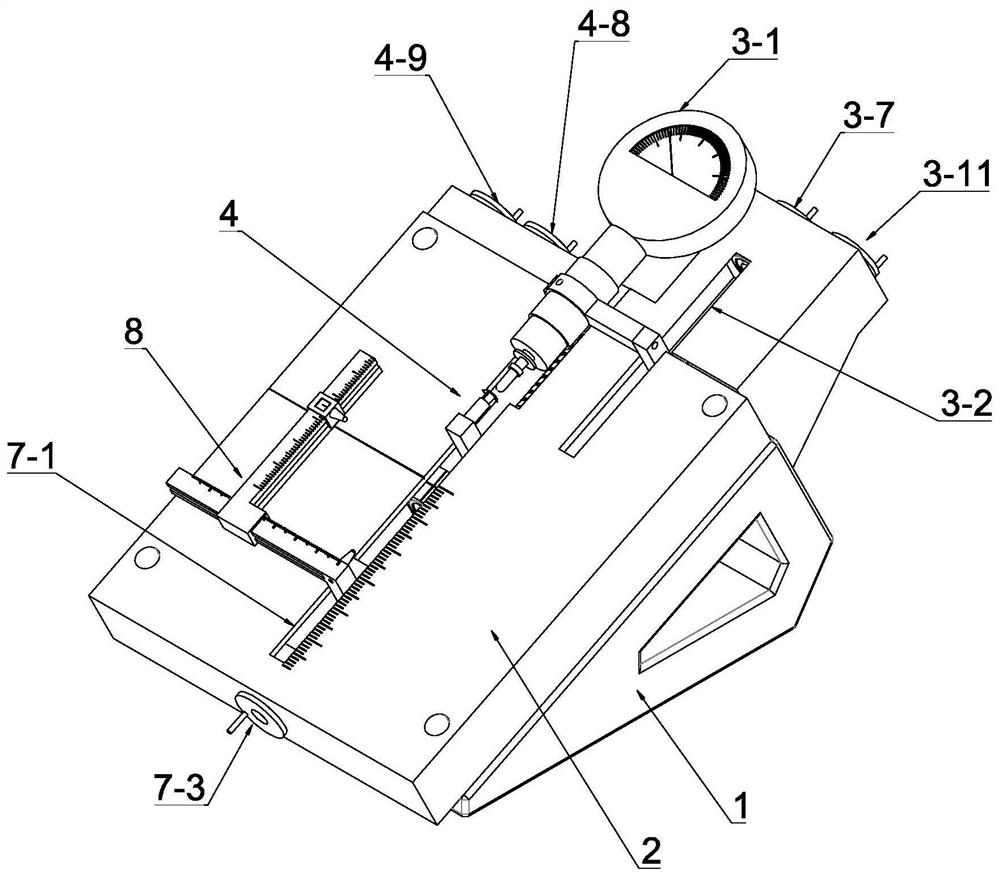

[0054] see Figure 1-Figure 5 , this embodiment discloses a device for measuring the outer diameter of a thin-walled bearing ring, including a support frame 1, a workbench 2 arranged obliquely on the support The positioning mechanism for positioning the bearing ring, the measuring mechanism 3 for measuring the outer diameter of the thin-walled bearing ring to be tested, the anti-resistance mechanism 4 for offsetting the measuring force generated by the measuring mechanism 3 for the thin-walled bearing ring to be tested, The annular electromagnetic mechanism 5 arranged at the lower end of the workbench 2 and the reinforcing rib 6 used to prevent elastic deformation when the positioning mechanism positions the thin-walled bearing ring; the workbench 2 is provided with a measurement center.

[0055] see Figure 1-Figure 5 , the positioning mechanism includes a Y-axis positioning mechanism 7 arranged on the workbench 2 for positioning the Y-axis direction of the thin-walled bearing...

Embodiment 2

[0088] see Figure 14, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that the X-axis adjustment mechanism includes the X-axis adjustment handle 8-6 that is rotated on the side of the worktable 2, and the upper edge of the worktable 2 is set. The X-axis guide groove 8-7 extending in the X-axis direction and the X-axis sliding block 8-8 slidingly matched with the X-axis guide groove 8-7, the X-axis adjustment handle 8-6 and the X-axis The sliding blocks 8-8 are connected by the X-axis screw drive assembly, the X-axis screw drive assembly is designed with reference to the above-mentioned Y-axis screw 7-5 drive assembly, the X-axis positioning rod 8-1 is connected to the X-axis The shaft sliding block 8-8 is fixedly connected, and the ball head of the X-axis positioning rod 8-1 faces the measurement center. By setting the above-mentioned mechanism, by manually turning the X-axis adjustment rocker 8-6, the X-axis screw drive assembly...

Embodiment 3

[0090] The structure of this embodiment is the same as that of Embodiment 1, except that the transmission assembly of the Y-axis screw rod 7-5, the transmission assembly of the measuring screw rod 3-5 and the transmission assembly of the positioning screw rod can all be driven by a synchronous belt. Way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com