Drainage solenoid valve, fuel cell cold start system and cold start method

A solenoid valve and cold start technology, applied in the direction of fuel cells, circuits, valve details, etc., can solve the problems of increasing system complexity, cost parasitic power and start time, affecting system cold start performance, heating PTC power is small, etc., to achieve Reduce cold start time, reduce ice breaking time, and reduce the effect of parasitic power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

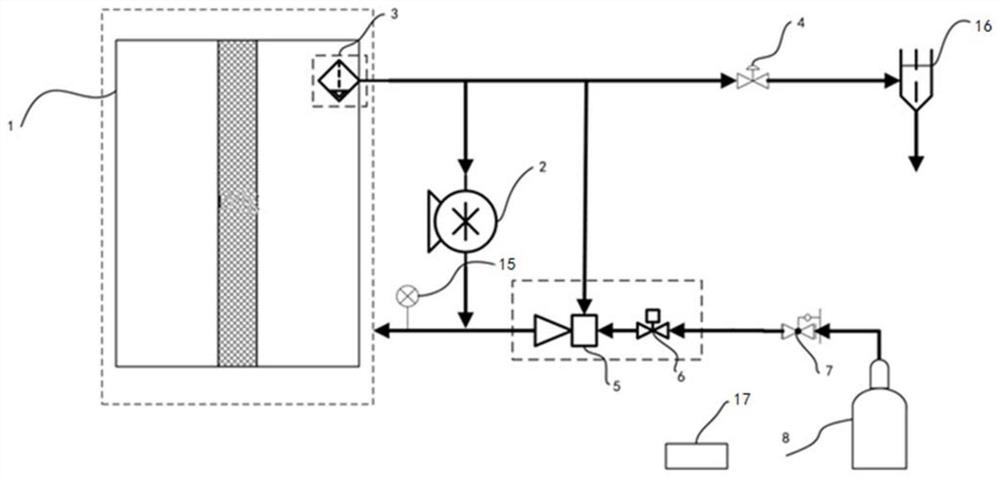

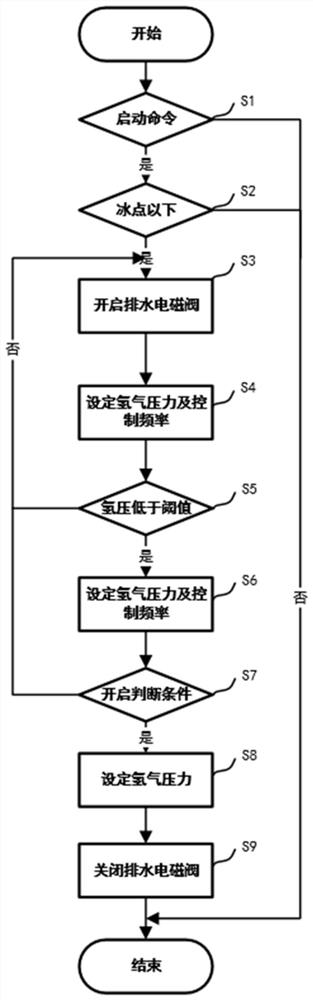

[0035] This embodiment provides a drain solenoid valve, a fuel cell cold start system and a cold start method.

[0036] Drain solenoid valve:

[0037] It includes a valve seat 9, a valve stem 10 and an electromagnetic coil 11. The electromagnetic coil 11 moves the valve stem 10 by energizing and de-energizing. The valve stem 10 and the electromagnetic coil 11 are installed on the valve seat 9, and the valve seat 9 forms a fluid inlet channel 13 and A diaphragm 12 is arranged between the fluid discharge passage 14, the fluid entry passage 13, the fluid discharge passage 14 and the valve stem 10, and the diaphragm 12 prevents the fluid from entering the passage 13 and the fluid discharge passage 14 from entering the valve stem 10 and the valve stem. The sliding gap formed between the seats 9. The fluid inlet flow channel 13 and the fluid discharge flow channel 14 are flush with the valve stem 10 , the diaphragm 12 is arranged on the flow channel contact surface of the valve ste...

Embodiment 2

[0046] The diaphragm 12 is connected with the valve seat 9, and the movement of the valve stem 10 makes the diaphragm 12 tense or loosen. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com