Online rock burst monitoring system and method based on support resistance monitoring

A technology of rock burst and monitoring system, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc., which can solve the problems of increased coal stress, low uniaxial compressive strength, and insufficient sensitivity of support resistance in monitoring effects, etc. Achieve the effects of improving monitoring accuracy, realizing real-time monitoring, early warning and forecasting, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

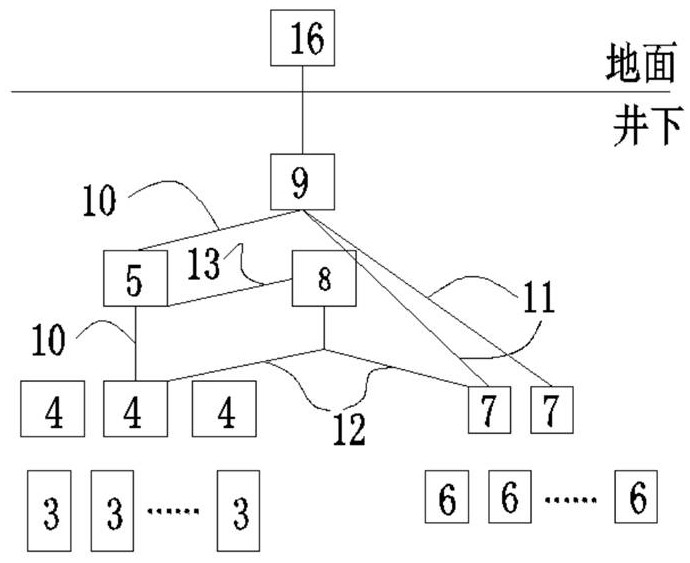

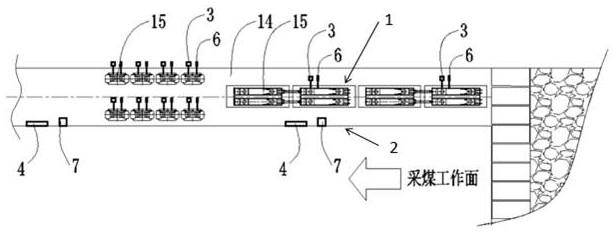

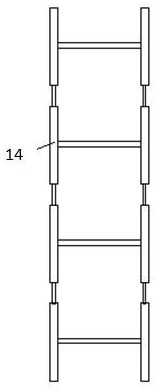

[0029] Such as Figure 1-3 As shown, an online monitoring system for rock burst based on support resistance monitoring includes a surface treatment system 16 located on the ground, an advanced online monitoring device 1 for hydraulic support resistance and a support positioning system 2 set up underground. The online monitoring device 1 for the resistance of the advanced hydraulic support and the support positioning system 2 are respectively connected to the downhole optical fiber ring network 9 and the explosion-proof type intrinsically safe power supply 8 for the underground; the online monitoring device 1 for the resistance of the advanced hydraulic support includes an advanced hydraulic support 14 installed The support pressure sensor 3 on the column pressure interface of the leading hydraulic support 14, the data co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com