Sunken-tube-method construction technology for laying main sewage intercepting pipe

A technology of construction technology and immersed tube method, which is applied in the direction of earth mover/shovel, construction, etc., to achieve the effect of blocking impact, simple structure and reducing lateral impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

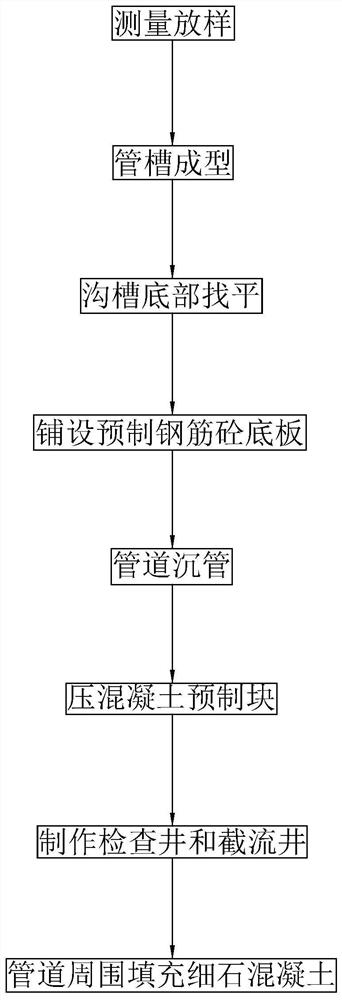

[0047] refer to Figure 1 to Figure 6 , which is an immersed pipe construction process disclosed in the present invention for laying sewage interceptors, including S1: measurement and stakeout. Measure the leveling points and guide points, and then set temporary axis control points and leveling control points at appropriate positions in the construction site as the control basis for immersed tube construction.

[0048] S2: pipe groove forming. For the river section with retaining wall built by masonry, the river bed is used as the foundation, and trenches for placing pipelines are excavated on the river bed.

[0049] During construction, the underwater earthwork excavation operation is carried out by using the positioning pile boat excavator. It should be excavated from top to bottom, and random digging is not allowed. As the excavation proceeded, the trench was extended from downstream to upstream along the bank retaining wall, taking care to avoid existing underground pip...

Embodiment 2

[0085] The invention discloses an immersed pipe method construction technology for laying sewage intercepting main pipes, including S1: measuring and setting out.

[0086] S2: pipe groove forming. For the river section with rocky mountains on both sides, use the rocky slope revetment as the foundation, and excavate grooves for placing pipelines on the rocky slope revetment.

[0087] During construction, water hydraulic breakers are used to drill along the pipeline axis on the slope protection of rock slopes and excavate trenches. The crushing is carried out in a top-down order, the above-water part is crushed first, and then the underwater part is crushed.

[0088] The width of the bottom of the trench finally excavated is 3m, the elevation of the bottom of the trench is 0.4m lower than that of the bottom of the pipeline, and the sides of the trench are sloped according to 1:0.5.

[0089] S3: Leveling the bottom of the groove. The gravel is transported to the vicinity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com