Side slope anchoring structure and frame beam supporting construction method using same

An anchoring structure and anchoring technology, which is used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of insufficient anchoring force and low sliding resistance of slope soil, so as to improve the anchoring force and ensure the splitting grouting pressure. and effect, the effect of improving sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The application will be further described in detail below in conjunction with the drawings.

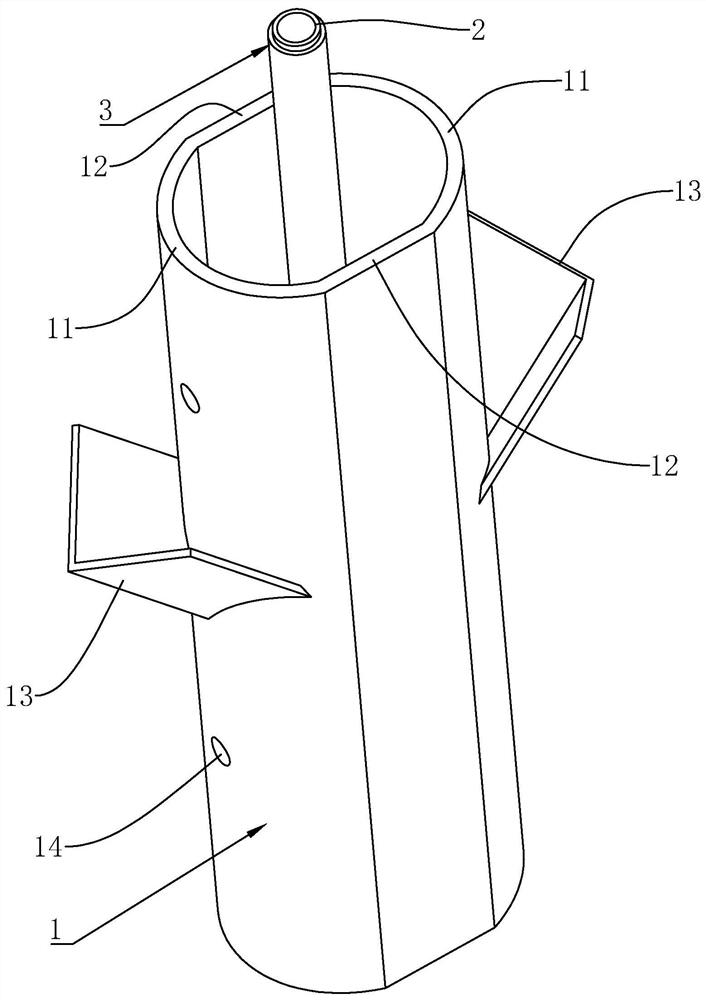

[0055] The embodiment of the application discloses a slope anchoring structure, according to figure 1 , Including an anchor steel pipe 1 and a grouting pipe 2 inserted in the anchor steel pipe 1, wherein the cross section of the anchor steel pipe 1 is oval-like, and the cross section of the anchor steel pipe 1 is divided into two symmetrically arranged arcs 11 and The straight part 12 between the two arc parts 11, the outer side of the anchor steel pipe 1 is symmetrically welded with an angle iron 13, and the anchor steel pipe 1 is provided with multiple split grouting holes 14, which are sealed by glass glue .

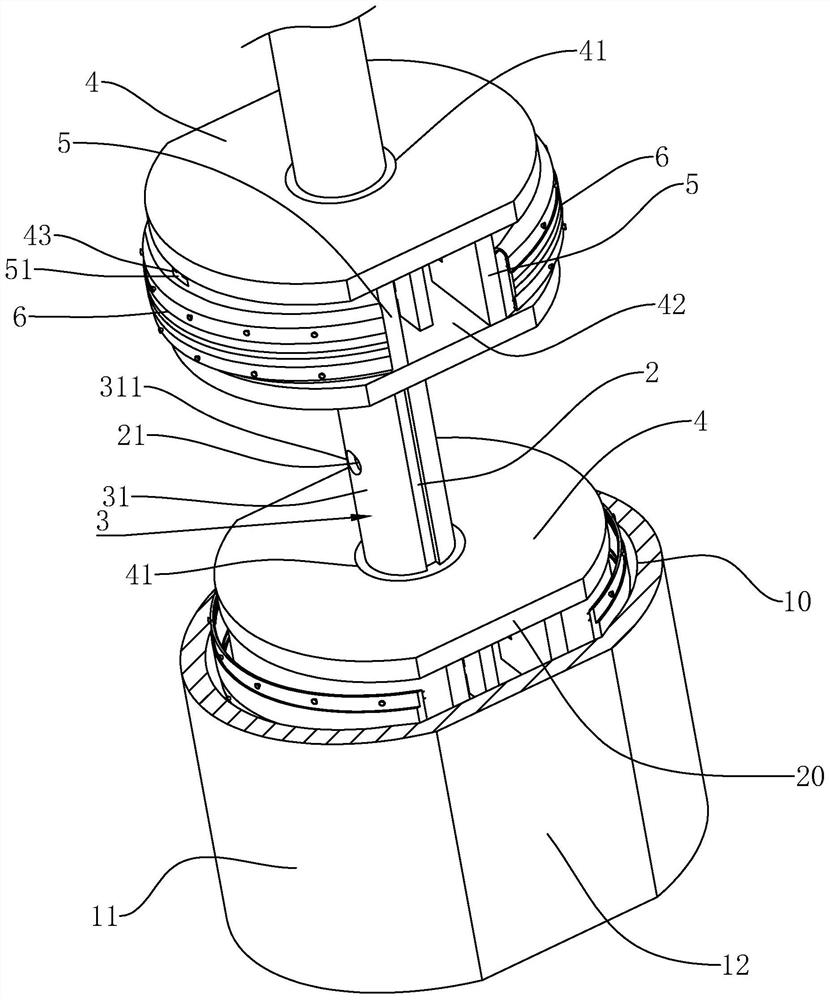

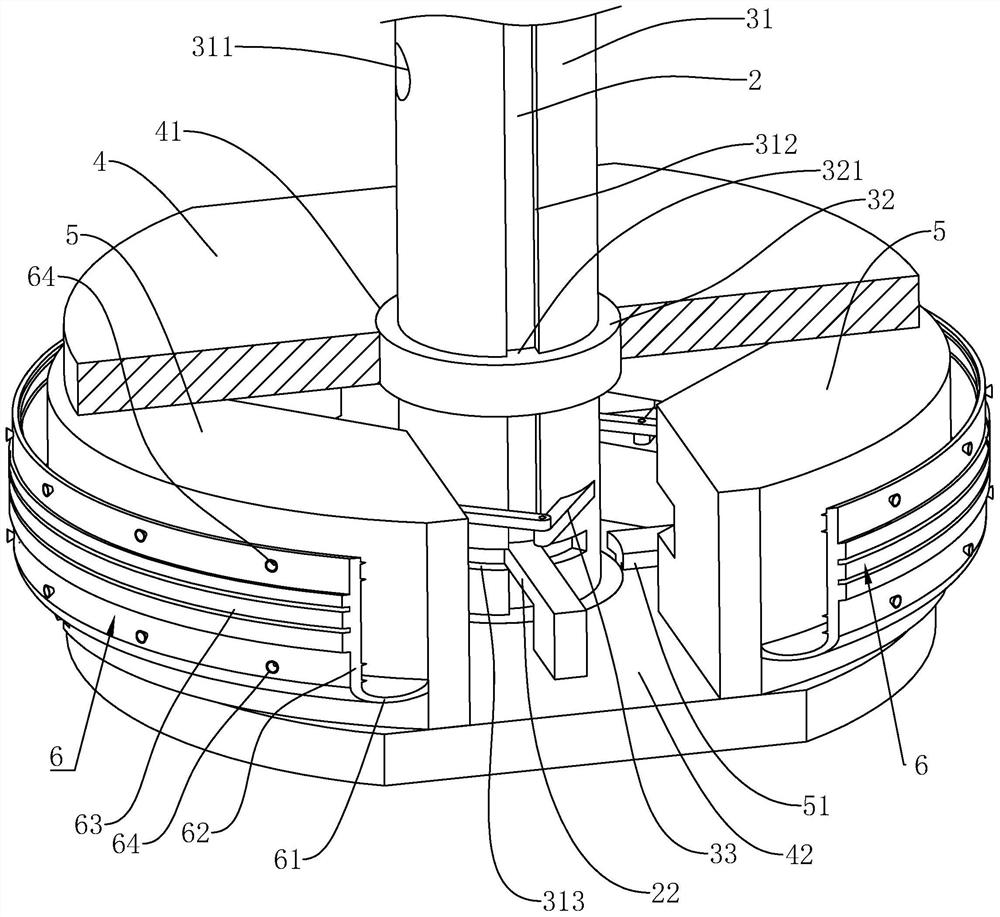

[0056] Such as figure 2 As shown, the side wall of one end of the grouting pipe 2 is provided with a grouting hole 21, and the grouting pipe 2 is sleeved and fixed with two grouting seats 4, and a flow is formed between the outer wall of the grouting seat 4 and the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com