A kind of preparation method of high-performance release paper

A high-performance technology for release paper, applied in pulp beating methods, papermaking, paper coatings, etc., can solve the problems of reduced use times, unstable peel strength, and increased cost of release paper, and achieve stable peel performance and excellent resistance. Oxidative aging ability, effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

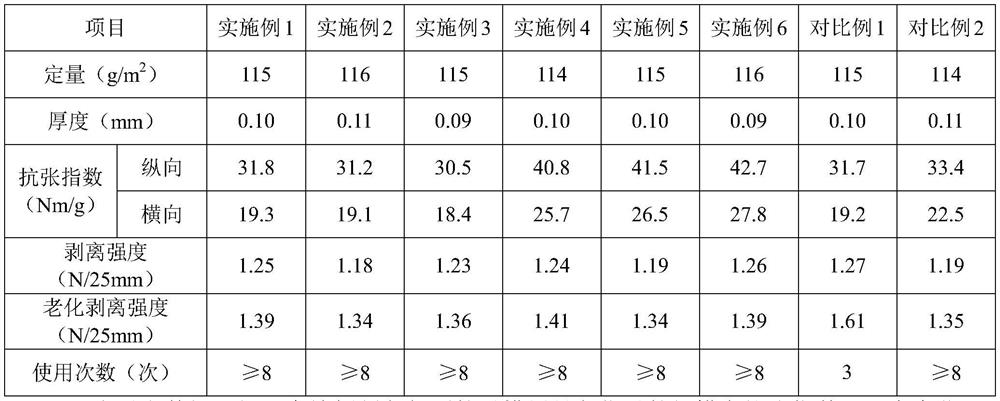

Examples

preparation example Construction

[0034] A method for preparing high-performance release paper, comprising the following preparation steps:

[0035](1) Select bleached kraft softwood pulp with a beating degree of 50-60°SR after refining as the raw material slurry, then add acrylic resin-coated titanium dioxide and mix evenly, and the addition amount per ton of paper is 80-120kg;

[0036] (2) Adding the sizing agent alkyl ketene dimer in the pulp, the addition amount is 0.08-0.3wt%;

[0037] (3) On the fourdrinier paper machine, carry out online copying, pressing and dehydration;

[0038] (4) The paper is first dried to a humidity of 25-35wt%, followed by semi-wet drying and pressure treatment at 90-110°C;

[0039] (5) Use starch for surface sizing, the amount of sizing is 0.8-2g / m 2 , followed by drying;

[0040] (6) Prepare base paper after spraying wetting, super calendering, coiling and slitting;

[0041] (7) Corona discharge treatment is carried out on the base paper, and then the anti-oxidation silico...

Embodiment 1

[0045] A method for preparing high-performance release paper, comprising the following preparation steps:

[0046] (1) the bleached kraft softwood pulp of 55 ° of SR is used as the raw material slurry after the degree of beating is selected for use;

[0047] (2) adding the sizing agent alkyl ketene dimer in the slurry, the addition amount is 0.15wt%;

[0048] (3) On the fourdrinier paper machine, carry out online copying, pressing and dehydration;

[0049] (4) The paper is first dried to a humidity of 30wt%, followed by semi-wet drying and pressure treatment at 100°C;

[0050] (5) Use starch for surface sizing, and the sizing amount is 1.3g / m 2 , followed by drying;

[0051] (6) Prepare base paper after spraying wetting, super calendering, coiling and slitting;

[0052] (7) Corona discharge treatment is carried out on the base paper, and then the anti-oxidation silicone emulsion is coated on the base paper, and the coating amount is 1.1g / m 2 , to prepare high-performance ...

Embodiment 2

[0055] A method for preparing high-performance release paper, comprising the following preparation steps:

[0056] (1) select the bleached kraft softwood pulp of 50 ° of SR as the raw material slurry after the beating degree is selected;

[0057] (2) adding the sizing agent alkyl ketene dimer in the slurry, the addition amount is 0.08wt%;

[0058] (3) On the fourdrinier paper machine, carry out online copying, pressing and dehydration;

[0059] (4) The paper is first dried to a humidity of 35wt%, followed by semi-wet drying and pressure treatment at 90°C;

[0060] (5) Use starch for surface sizing, the amount of sizing is 0.9g / m 2 , followed by drying;

[0061] (6) Prepare base paper after spraying wetting, super calendering, coiling and slitting;

[0062] (7) The base paper is treated with corona discharge, and then the anti-oxidation silicone emulsion is coated on the base paper, and the coating amount is 1g / m 2 , to prepare high-performance release paper after drying; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com