Blade edge passivating treatment device for electromechanical equipment accessory production

A technology of electromechanical equipment and passivation treatment, applied in the direction of metal material coating process, etc., can solve the problems of low efficiency, single structure, waste, etc., and achieve the effect of uniform distribution, avoiding pollution and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

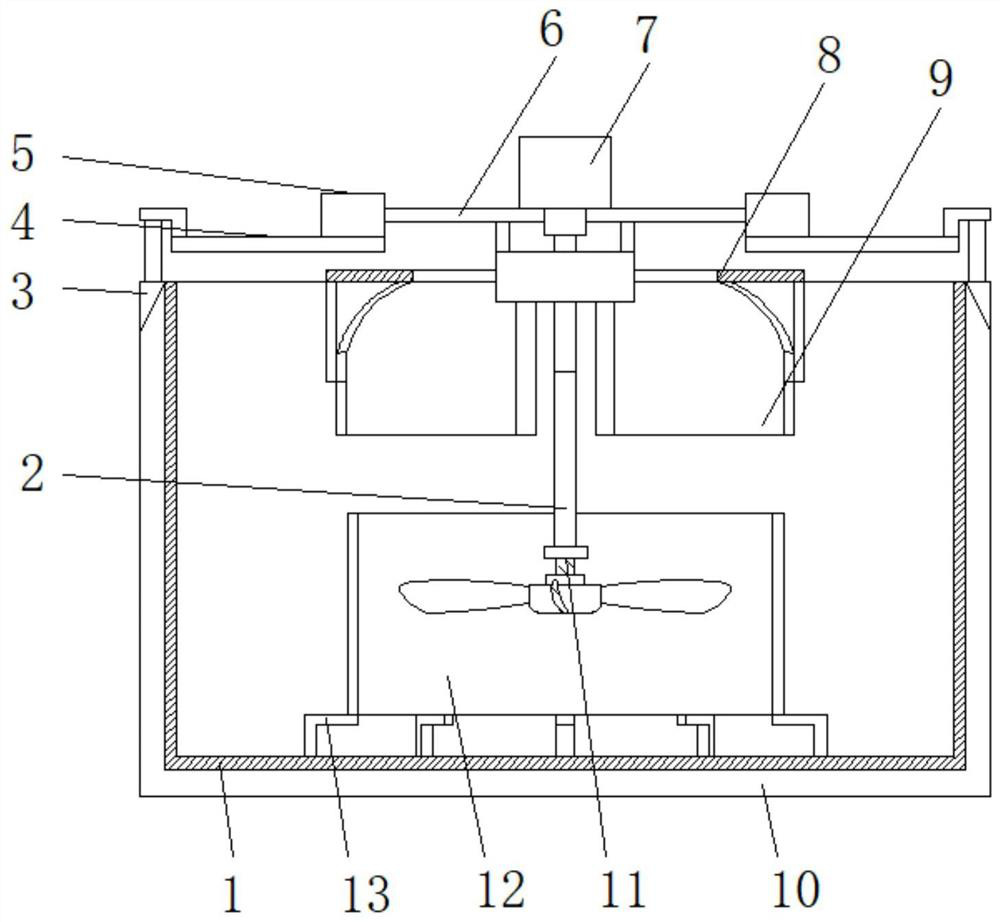

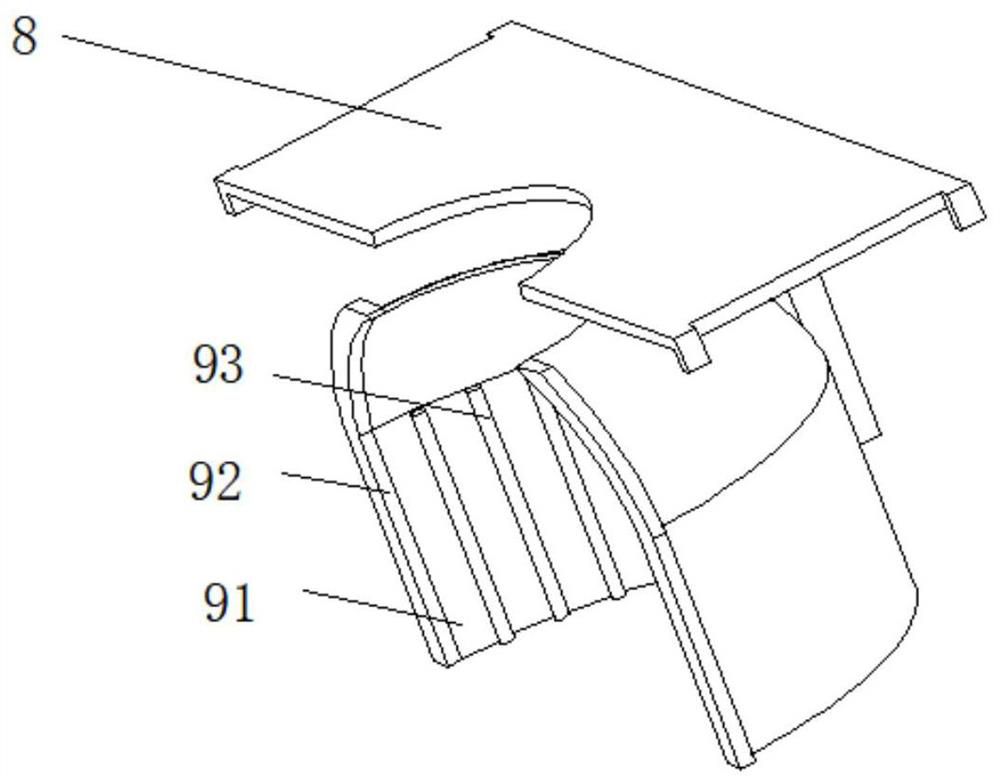

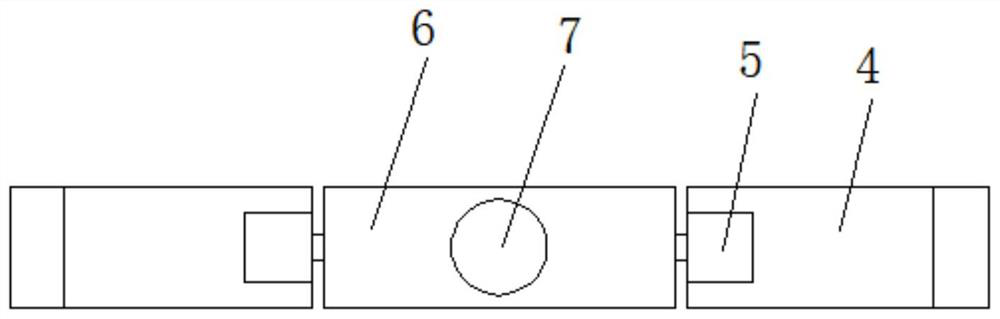

[0027] Reference Figure 1-4 , A blade edge passivation treatment device for the production of electromechanical equipment accessories, comprising a pool body 1. Electric push rods 3 are fixedly installed on both sides of the pool body 1, and a jacking plate 4 is fixedly installed on the top of the electric push rod 3, A stepping motor 5 is fixedly installed on the top of the two lifting plates 4, and a flipping plate 6 is fixedly installed between the output shafts of the two stepping motors 5, and a driving motor 7 is fixedly installed on the top of the flipping plate 6, and the driving A rotating rod 2 is fixedly installed at the bottom end of the output shaft of the motor 7, a mounting seat 11 is fixedly installed at the bottom end of the rotating rod 2, and a plurality of L-shaped support frames 13 are fixedly mounted on the bottom inner wall of the pool body 1, and the support frames 13 A slow-flow mechanism 12 is fixedly installed between the top ends of the device, a bru...

Embodiment 2

[0037] Reference Figure 1-3 with Figure 5 , A blade edge passivation treatment device for the production of electromechanical equipment accessories. Compared with the first embodiment, the slow flow mechanism 12 includes two fixed rings 125 distributed up and down, and the two fixed rings 125 are fixedly installed A plurality of baffle plates 124 arranged obliquely with arc-shaped structures, and a slow flow groove 123 provided between two adjacent baffle plates 124.

[0038] In this embodiment: when the blades in the device are rotating, the deflector 124 with the arc-shaped structure inclined to guide the solution, reduce the impact of the flowing solution, avoid splashing of the solution, and the solution passes gently inside the deflector 124 The flow trough 123 conducts flow diversion and slowly rotates around the inside of the pool body 1 to accelerate the effect of the passivation agent blending and make the passivation agent solution evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com