Fast automatic rolling, slitting and counting top machine equipment

A counting type, top machine technology, applied in the field of top machine, can solve the problems of poor quality, sparse wool, sparse top short hair, etc., to achieve uniform distribution, good quality, and improve the winding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the present invention's fast automatic winding, slitting, counting and counting wool top machine equipment in conjunction with the accompanying drawings.

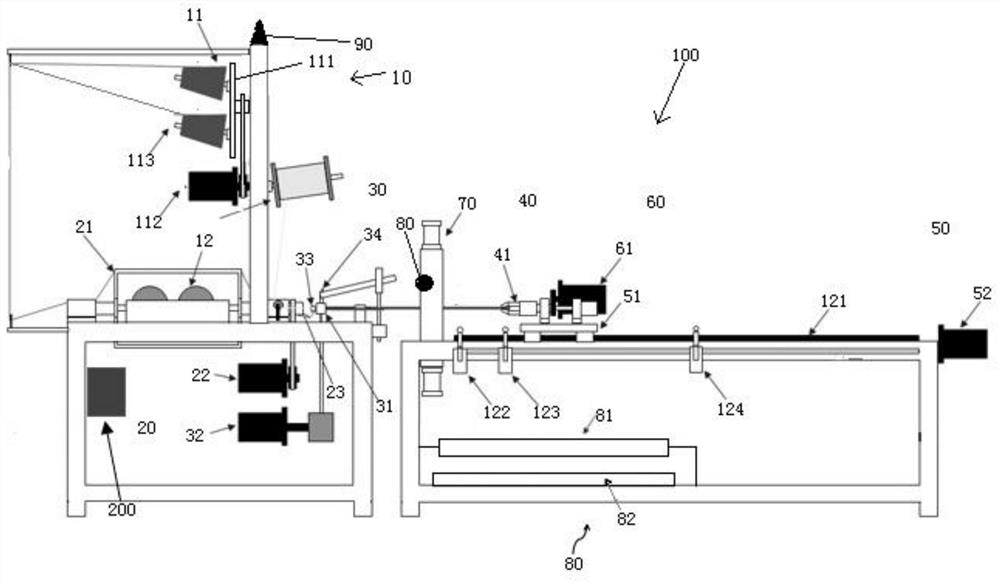

[0031] figure 1 It is a schematic structural diagram of the fast automatic winding, slitting and counting top machine equipment in the embodiment of the present invention.

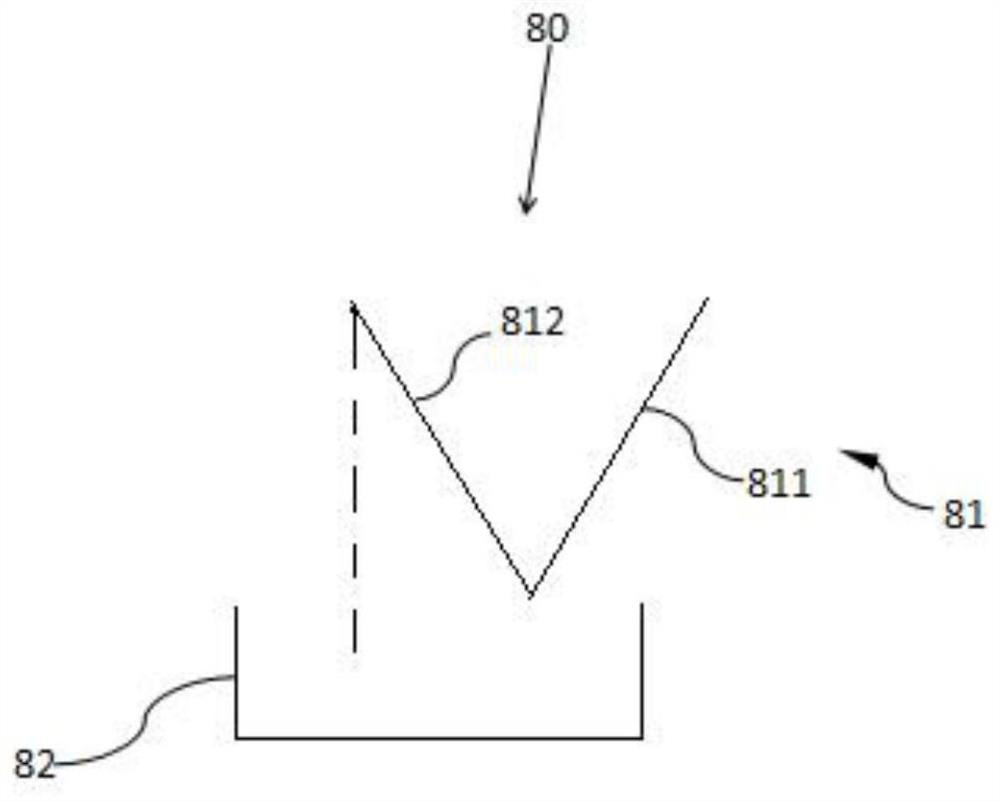

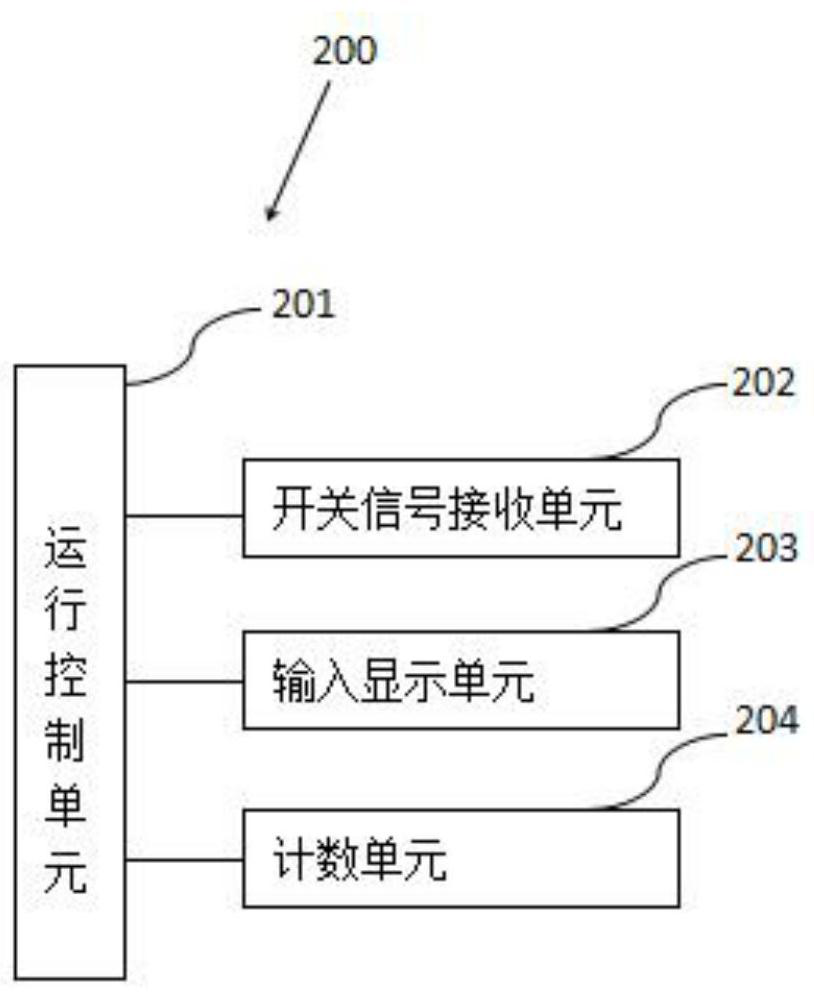

[0032] like figure 1 As shown, the fast automatic rolling, cutting and counting type wool top machine equipment 100 in this embodiment is used for rapid production of wool tops, including a frame, a wire supply mechanism 10, a winding mechanism 20, a wire feeding mechanism 30, a clamping mechanism 40, Wire drawing mechanism 50 , winding mechanism 60 , cutting mechanism 70 , top storage mechanism 80 , alarm mechanism 90 and control unit 200 . Wherein, the output part includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com