Inductor production equipment and production method

A technology for production equipment and inductance, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of low production efficiency, high cost, hindering the change of current, etc., to achieve fast winding speed and high processing efficiency , the effect of precise winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

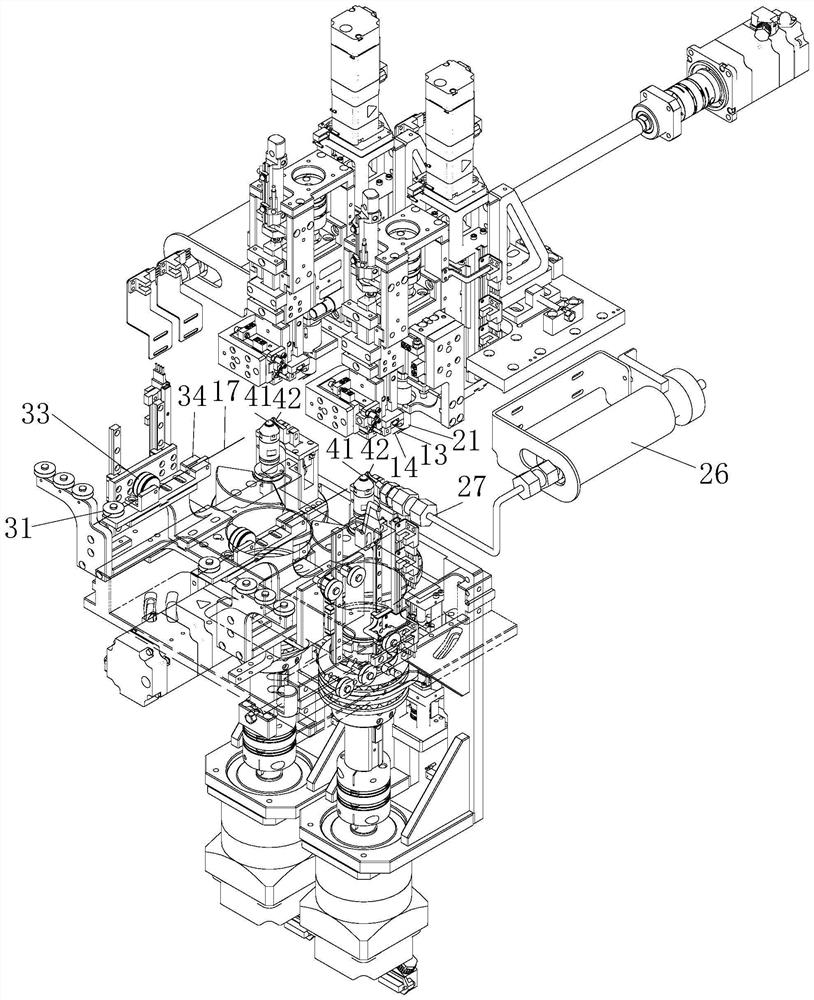

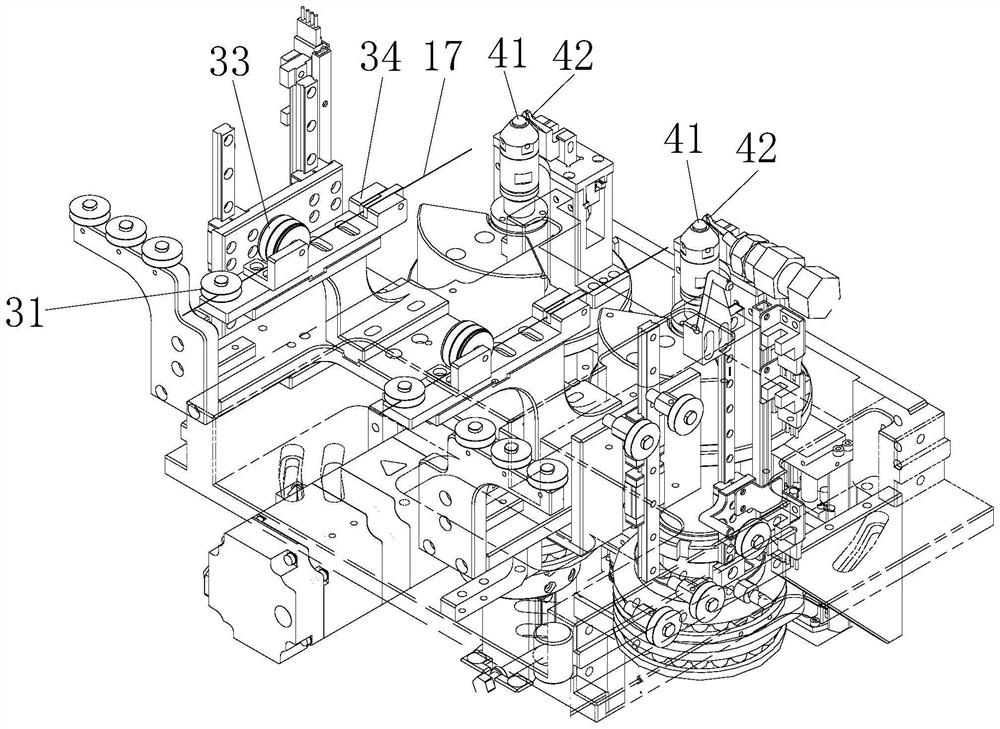

[0045] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0046]The product to be processed is an inductor 1 . The inductor 1 includes a flat portion 11 and a cylindrical portion 12 protruding from the surface of the flat portion 11 . The surface area of the flat portion 11 is greater than that of the cylindrical portion 12 . The finished product after winding on the inductance 1 is used in mobile phones, and the winding wire is TCORE core wire. The size of the inductance is small, the length of the flat part 11 is 1-2mm, the width is 0.5-1mm, and the height is 0.1-0.3mm. The cylindrical part is elliptical, and the height of the cylindrical part 12 is 0.3-0.5mm. The flat portion 11 of the inductor has a length of 2mm, a width of 1mm, and a height of 0.25mm. The height of the cylindrical portion 12 is 0.46mm, and the major axis is 0.5mm.

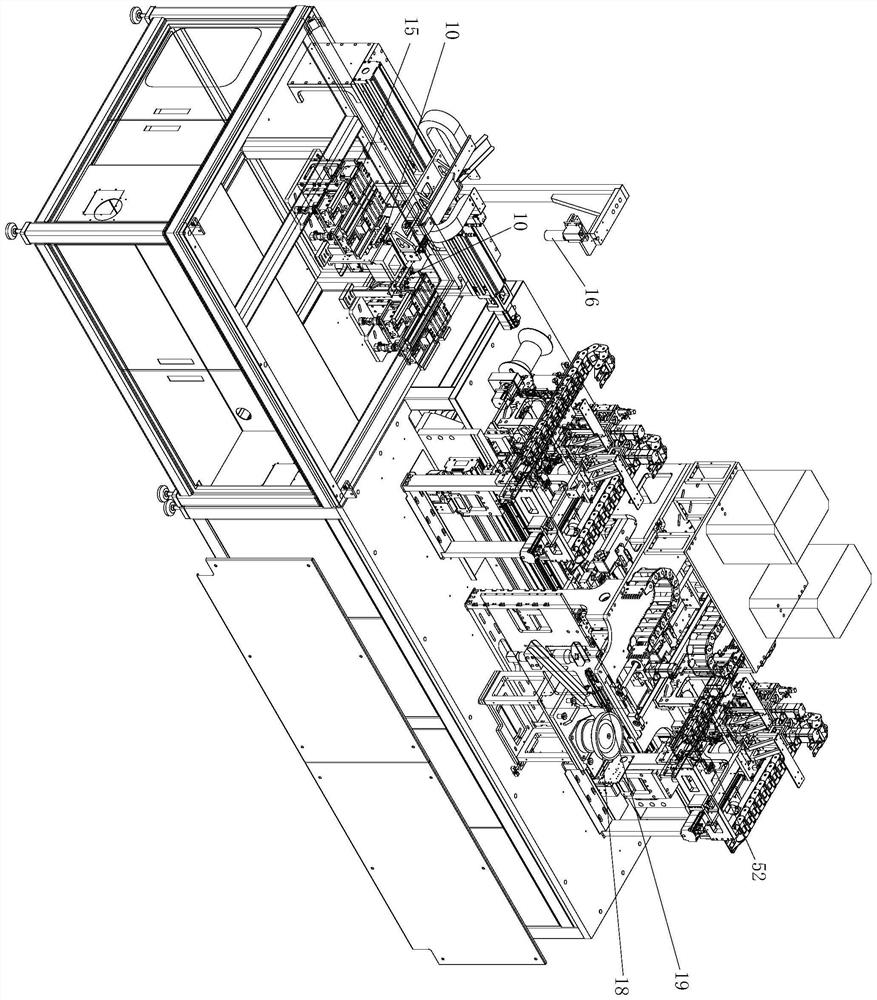

[0047] Such as Figure 1 to Figure 12 The inductor 1 windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com