Sand and stone centrifugal screening equipment for constructional engineering

A technology of construction engineering and centrifugal sieve, which is applied in the field of sand and gravel separation, and can solve the problems of easy dampness of sand and gravel, inconvenient discharge of gravel, difficulty in filtering and separating sand and gravel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

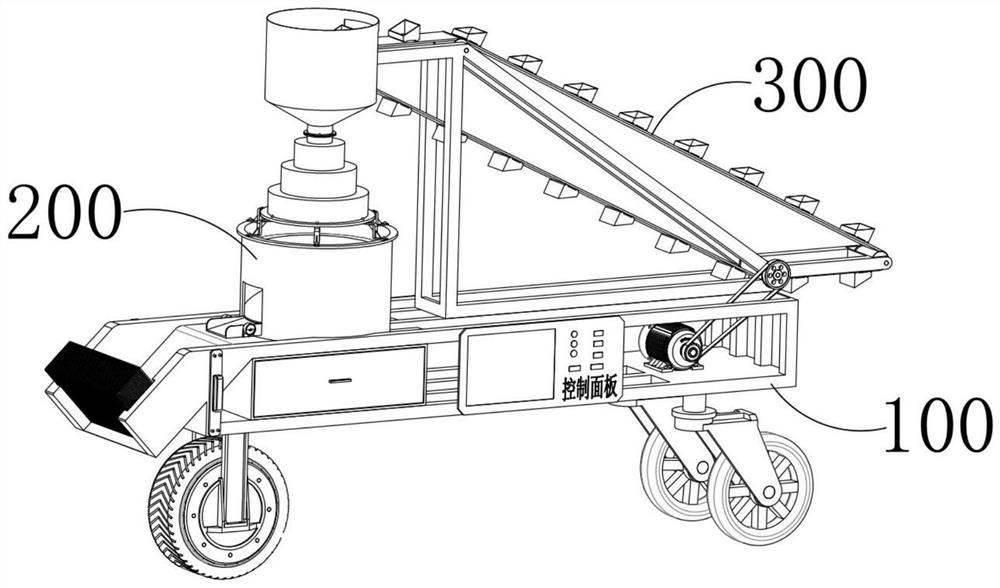

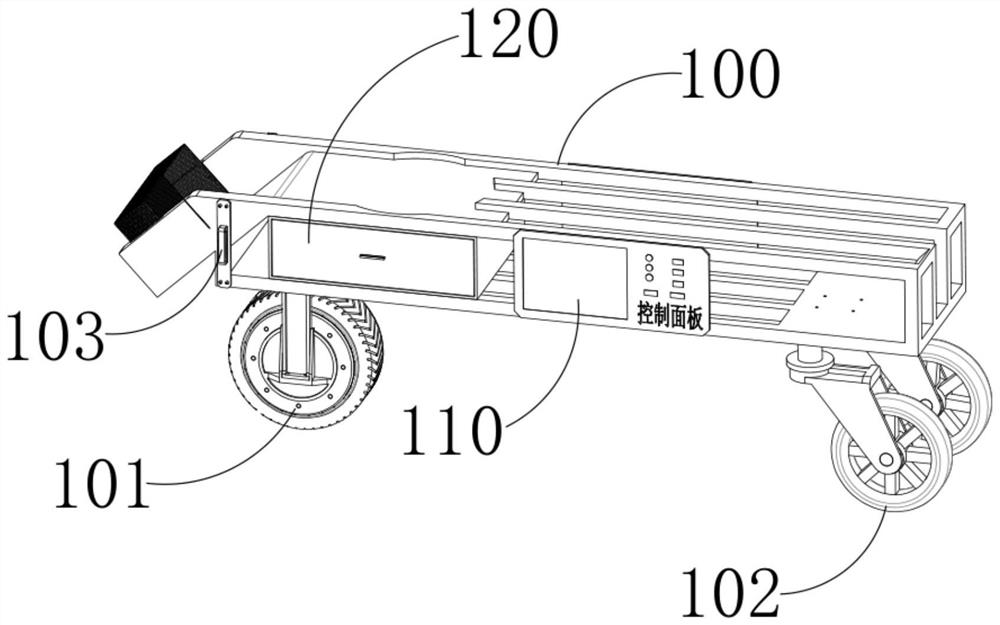

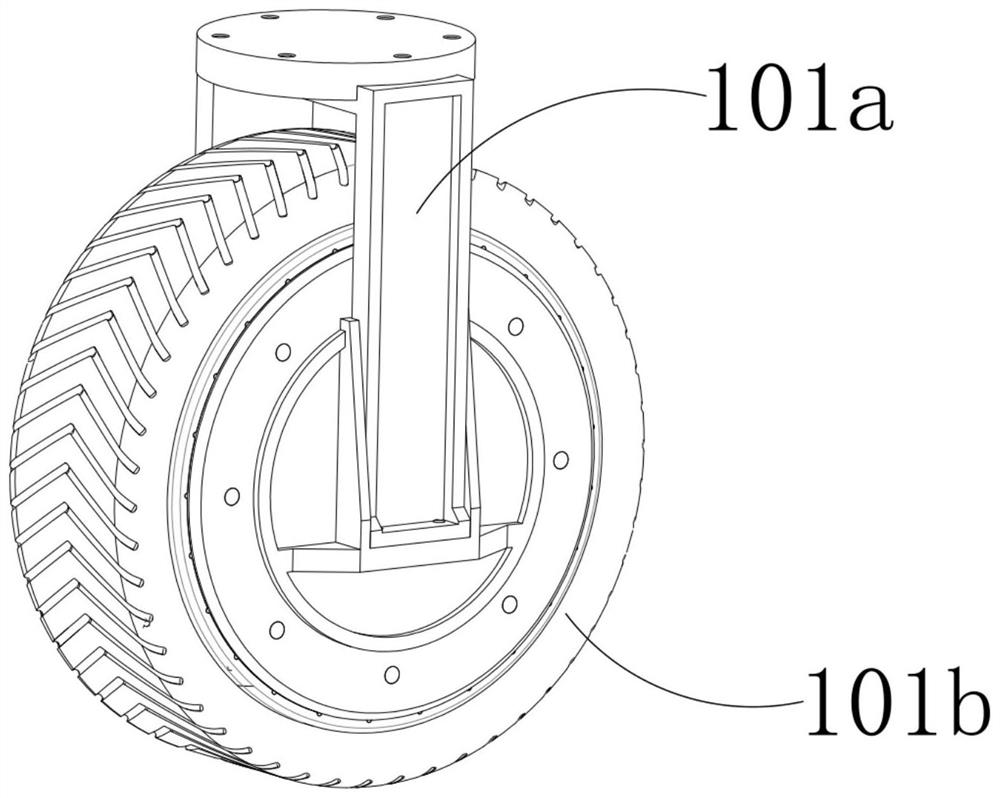

[0071] see Figure 1-30 , a sand and gravel centrifugal screening equipment for construction engineering, which includes a travelable rectangular hollow frame 100, a separating device 200 and a conveying device 300, one end of the frame 100 along its length direction is the front end in the direction of travel, and one end along its length The other end of the direction is the rear end of the travel direction, the separation device 200 is fixedly arranged on the upper end surface of the frame 100 and is arranged close to the front end of the frame 100, and the conveying device 300 is fixedly arranged on the upper end surface of the frame 100 and is close to the rear end of the frame 100 Arranged, the conveying device 300 is used to supply sand to the separation device 200, and the separation device 200 is used to dry and centrifuge the sand and first discharge the sand and then discharge the stones to the outside.

[0072] see Figure 10-15, the separation device 200 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com