Stock breaking device for automatic grafting of apple trees

A technology of apple tree and broken anvil, which is applied in the field of agricultural automation and planting. It can solve the problems of low degree of automation in apple tree grafting and difficulty in realizing automation, and achieve the effects of reducing the intensity of workers' work, increasing the success rate, and improving working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

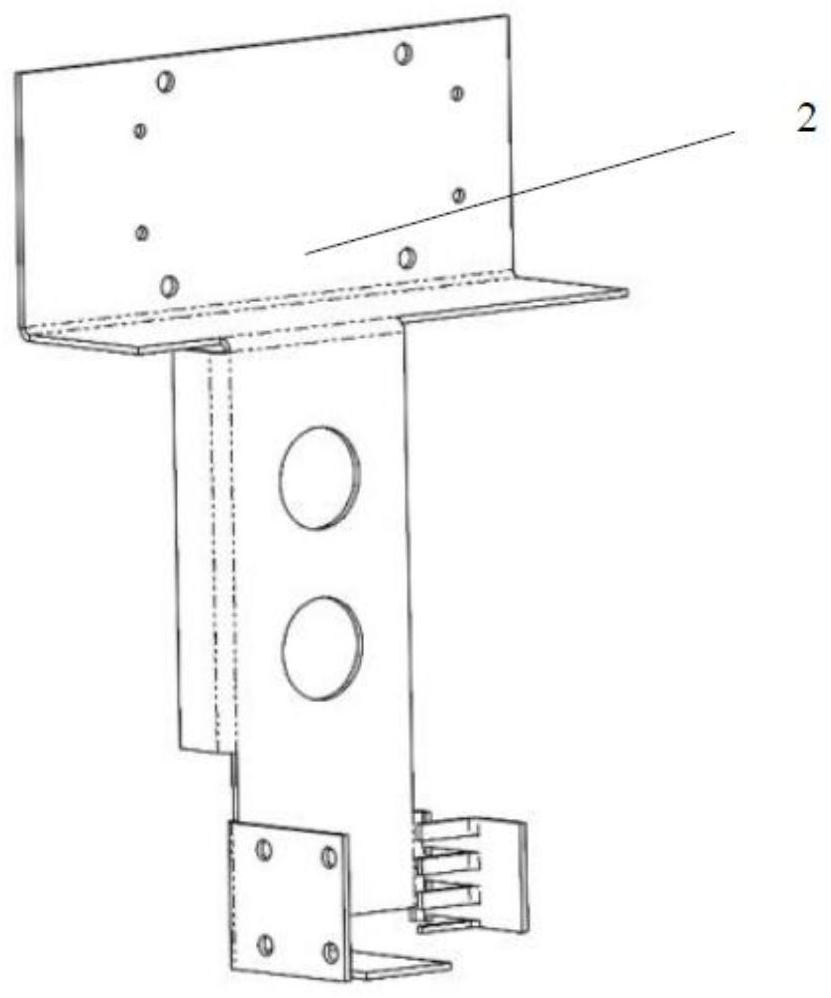

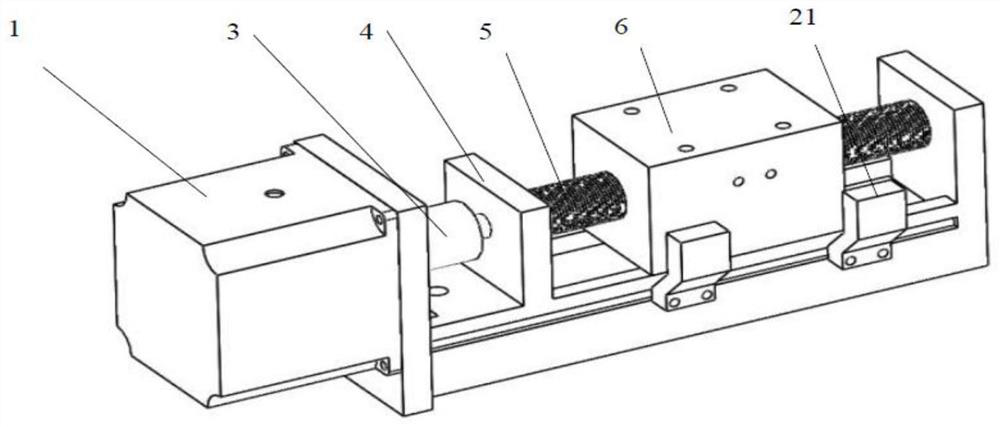

[0012] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings. like Figure 1 to Figure 5 As shown, the anvil-breaking device for automatic grafting of the present invention includes a fixed plate (2), a slide base (4), a screw (5), a stepping motor (1), a travel switch (21), and a cylinder mounting plate (7) , oblique cutting cylinder (11), vertical cutting cylinder (9), clamping cylinder (27), clamping claws (17), vertical cutting knife holder (22), vertical cutting blade (25), clamping cylinder bolt (26 ). The rootstock is leaned against the positioning plate (18) at the lower end of the fixed plate, and the upper end of the stock is exposed by 20-30mm, and the clamping cylinder (27) promotes the clamping claws (17) to move and clamp the stock. The stepper motor (1) drives the lead screw (5) to rotate to move the slide block (6), so that the oblique cutting cylinder (11) and the vertical cutting cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com