A kind of preparation method of diffusion layer for fuel cell

A fuel cell and diffusion layer technology, which is applied in the preparation/purification of carbon, battery electrodes, circuits, etc., can solve the problems of reducing the usable time of diffusion layers and catalysts, and achieve the effect of improving the degree of bonding, ensuring quality, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

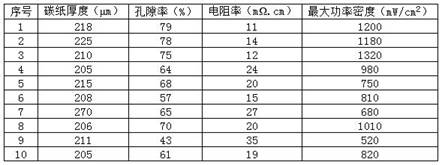

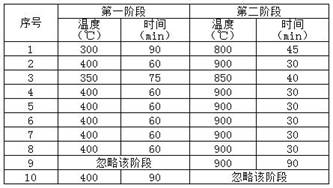

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0019] First, the diffusion layer is produced as follows:

[0020] S1. Prepare the straw material: take the corn stalk after the corn is mature, remove the outer skin of the corn stalk, take the straw material at the soft part of the center of the corn stalk, and then dry the straw material, and control the water content in the straw material at 10-15wt%;

[0021] S2. forming a suspension: cutting the straw material into long strips, the length of the straw material is 200-1000 μm, then placing it in acetone to form a polar solution, and fully stirring and mixing;

[0022] S3. Mixing functional substances: Add SiC particles and carbon oxide materials to the acetone solution and stir thoroughly. The mesh size of ceramic particles and carbon oxide materials is not less than 300 mesh, and then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com