Method for compensating surface product defects of automobile outer covering part

A technology of outer cover and compensation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high cost and long rectification time, so as to improve the quality of noodle products, reduce the workload of training, shorten the The effect of the debug cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

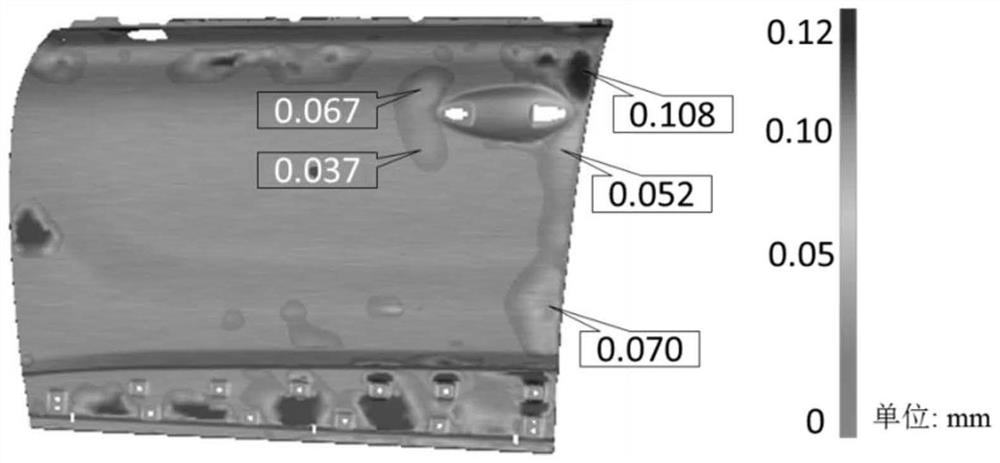

[0063] The door panel product model of a car is as follows: figure 2 As shown, according to the model, after the stamping process design is completed, surface product defects need to be compensated, and the specific steps are as follows:

[0064] The first step is to obtain the analysis results of surface product defects before compensation, and the sub-steps are:

[0065] (1) Finite element analysis of product defects before compensation: Construct surface product defect analysis files in the plate forming finite element analysis software Autoform. Among them, the material parameters are shown in Table 1, and the tool and sheet mesh size parameters are shown in Table 2.

[0066] Table 1 Material parameters of a certain car door panel

[0067]

[0068] Table 2 Tools and sheet metal grid size parameters

[0069]

[0070] (2) Evaluation of product defect results before compensation: Use the Surface command in the Evaluation of Autoform software to perform quantitative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com