Icing real-time monitoring system based on fiber Bragg grating

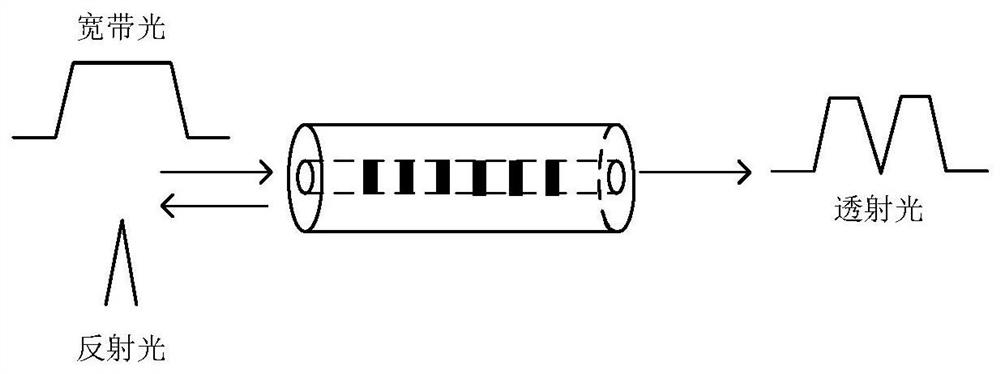

A technology of fiber Bragg and fiber grating, which is applied in the direction of measuring, measuring force, and measuring device by measuring the change force of the optical properties of the material when it is stressed, and can solve the problems of short service life, electromagnetic interference signals of electronic sensors, instability, etc. problem, to achieve the effect of small size and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In order to solve the above problems, the present invention proposes a real-time monitoring system for ice coating based on fiber Bragg gratings, which realizes online real-time monitoring of the thickness of ice coating on OPGW optical cables.

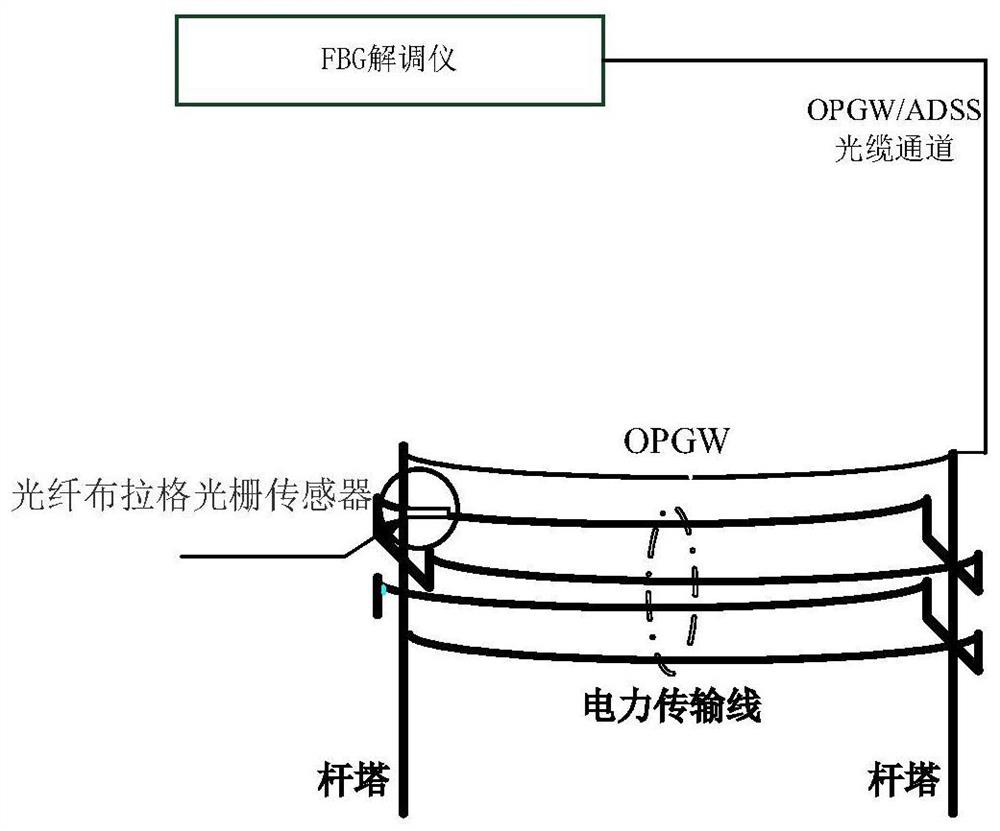

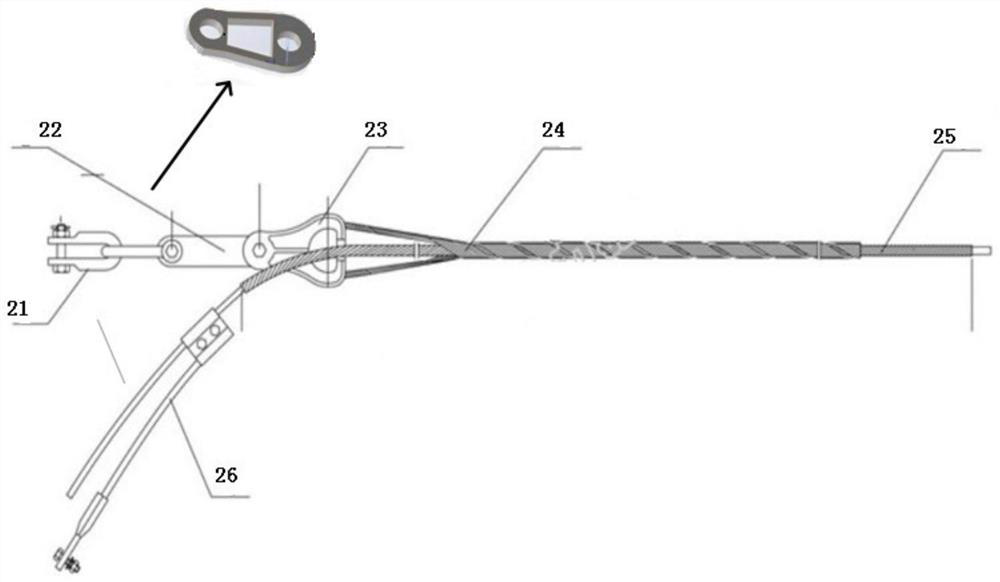

[0055] Such as figure 1 Shown is a schematic diagram of a real-time monitoring system for ice coating based on fiber Bragg gratings. The monitoring system includes OPGW optical cables, fiber Bragg grating sensors, and fiber grating demodulators. The fiber Bragg grating sensors can measure the wavelength deviation caused by the thickness of ice coating. The displacement, so that the real-time measurement of the ice thickness of the optical cable can be realized. Such as figure 2 Shown is a schematic diagram of a system for fiber grating measurement of icing. The PD hanging plate at the connection of the optical cable of the present invention adopts a cantilever beam 22 with a triangular structure, and the two ends of the trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com