Tunnel ditch builder's staging

A ditch and tunnel technology, applied in tunnels, tunnel lining, drainage, etc., can solve the problems of time-consuming handling and disassembly, large manpower consumption, and easy-to-bend gutters, so as to improve handling efficiency, increase efficiency, and reduce unevenness deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

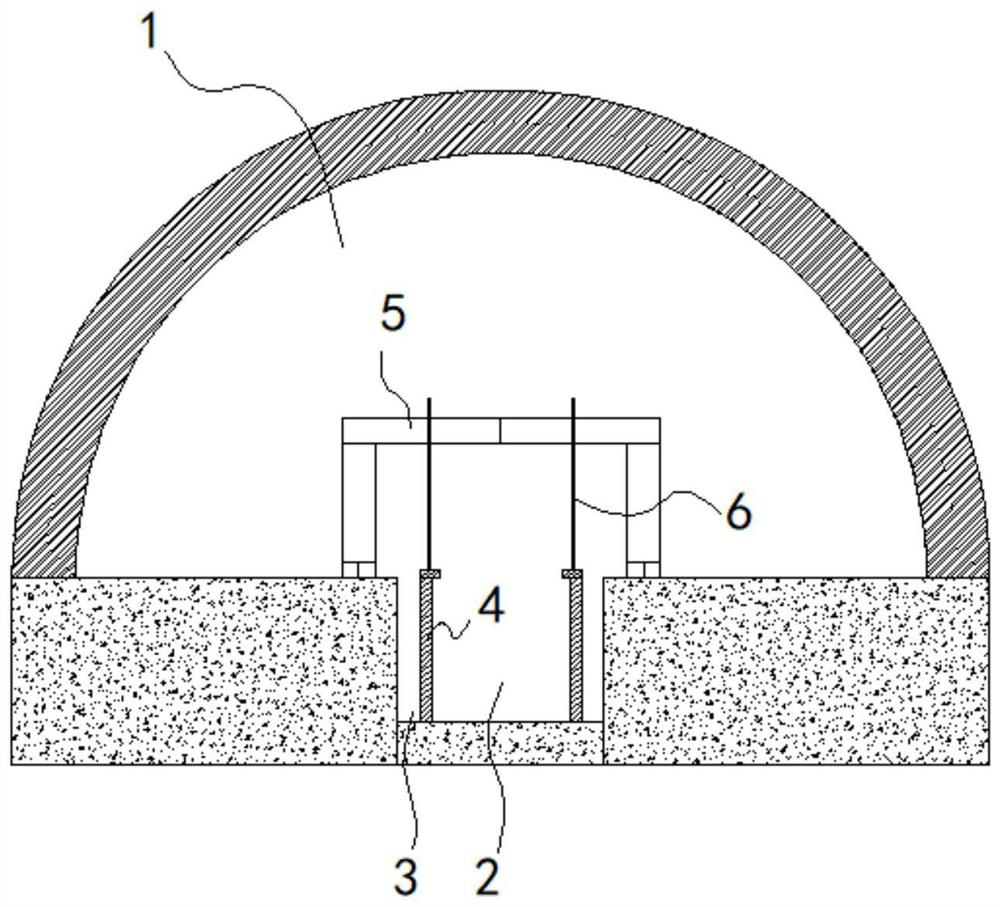

[0035] Such as figure 1 As shown, when constructing in the tunnel 1, it is necessary to put the left plate and the right plate into the ditch 2, and then pour cement into the gap 3 between the left plate and the right plate and the ditch wall, and remove it after setting The ditch of the target specification is obtained only by the left plate and the right plate.

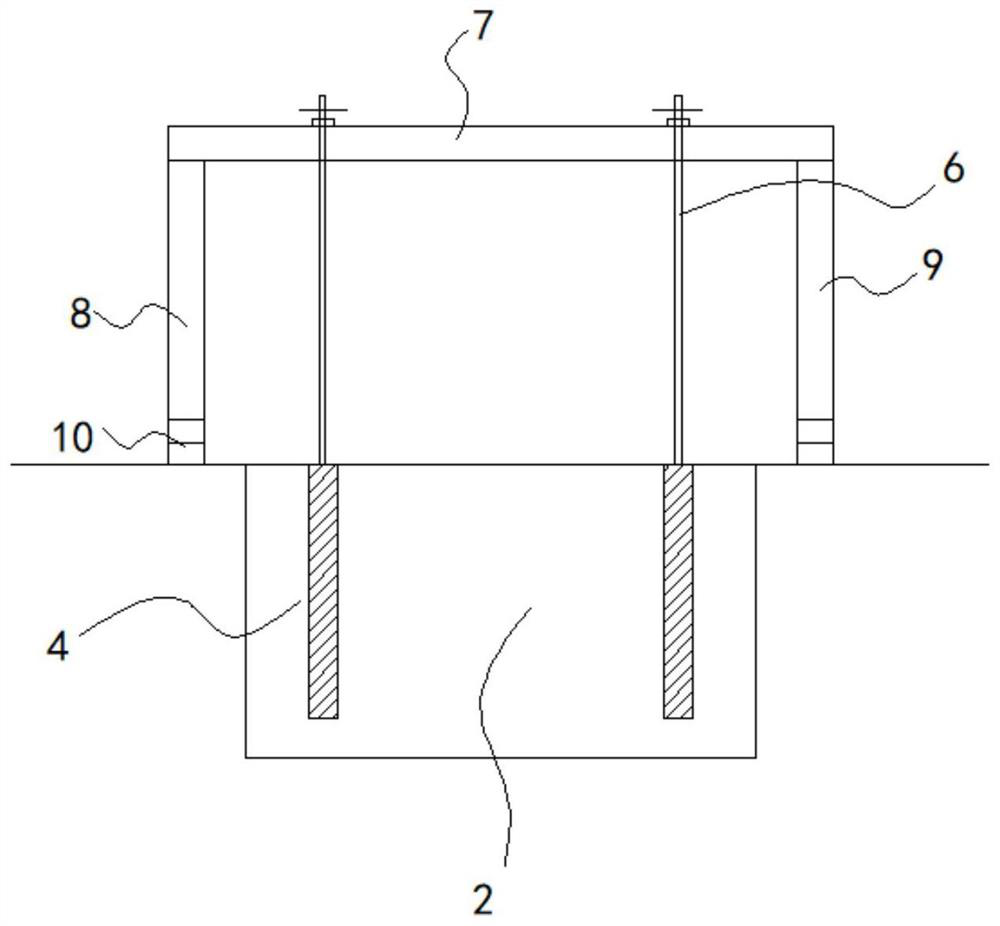

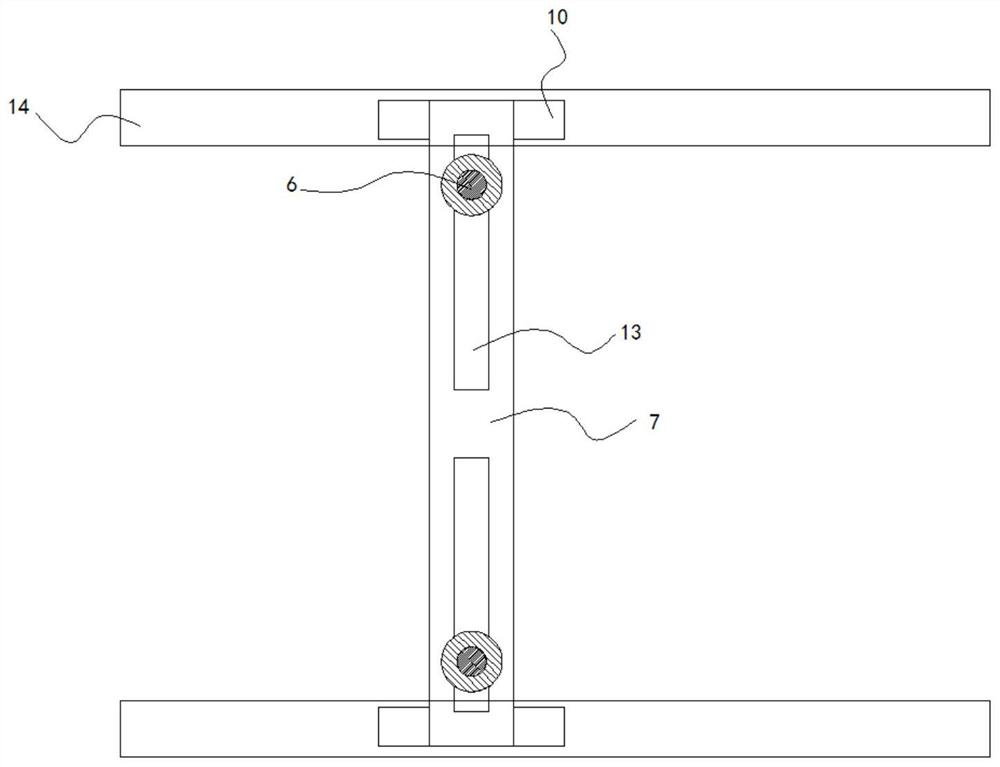

[0036] For better construction, such as figure 1 , 2 , 3, 4 and 5, a tunnel ditch construction platform, including:

[0037] A support frame 5 that can move in the tunnel, the support frame includes left and right support rods (8, 9) and crossbeams 7 horizontally erected on the left and right support rods, and the lower ends of the left and right support rods (8, 9) are provided with The wheels 10 move in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com