Rope ladder storage rack

A technology for storage racks and rope ladders, applied to ship accessories, passenger handling equipment, ships, etc., can solve problems such as infirmity, unsightly appearance, collapse, etc., and achieve shipowner satisfaction, increase applicability, and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

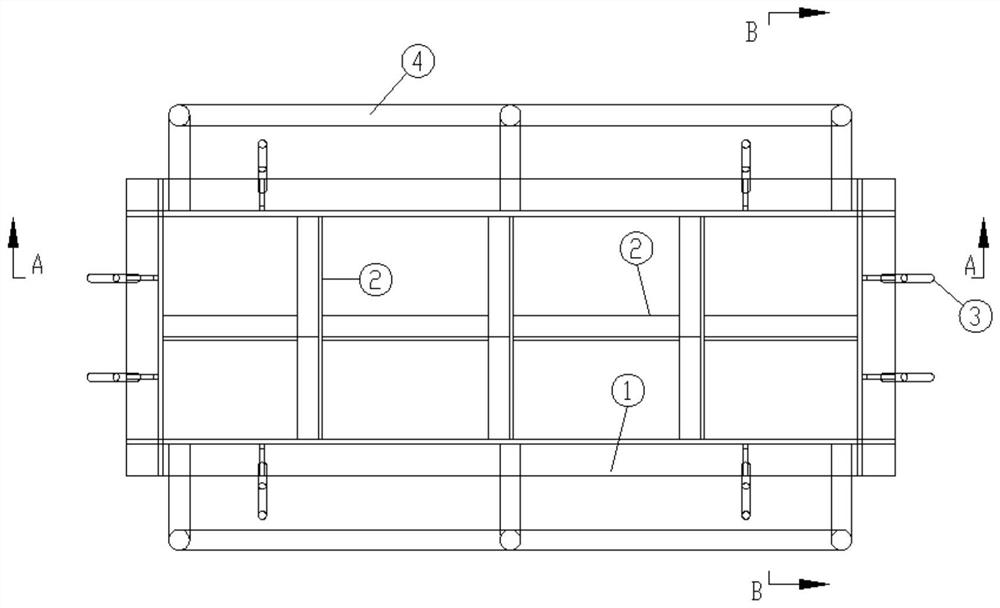

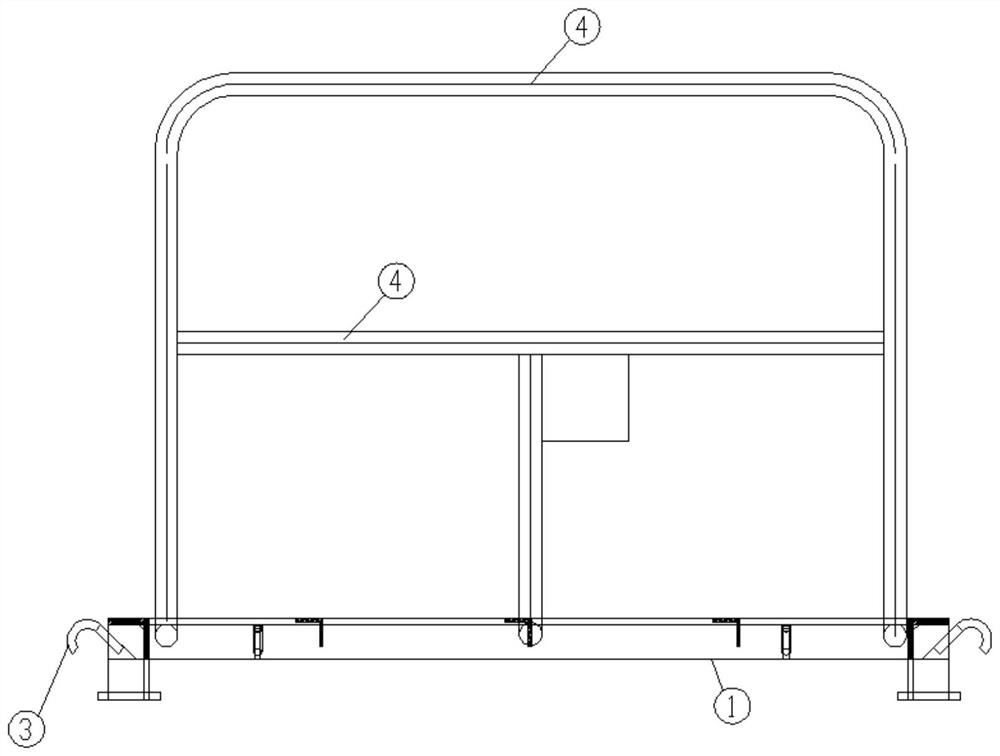

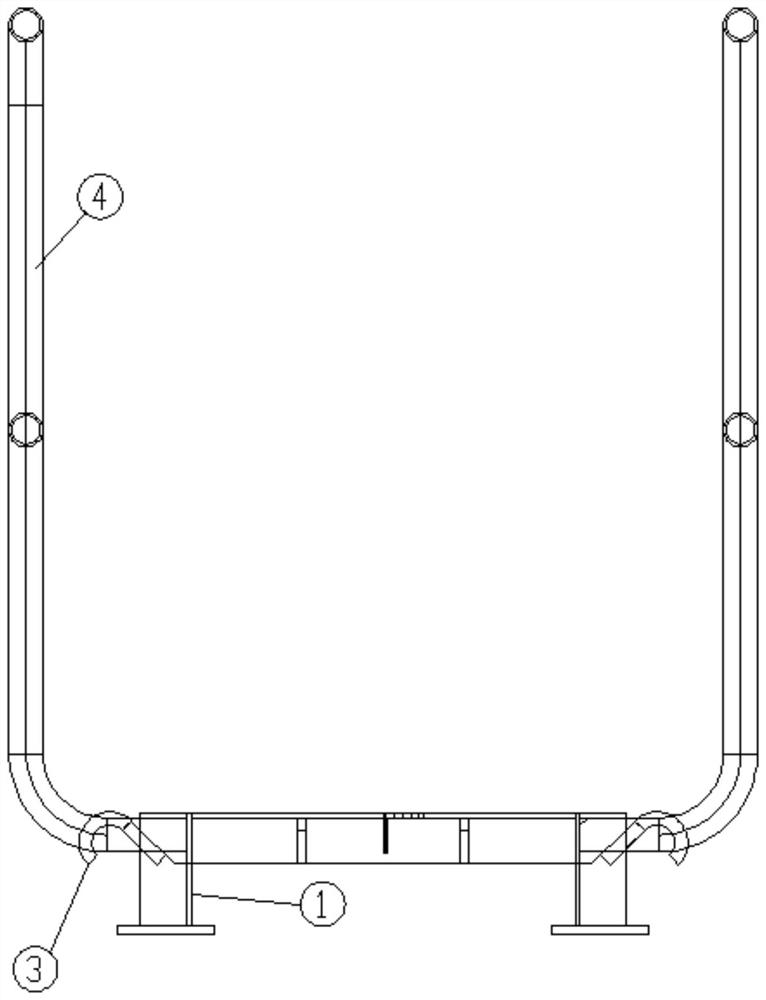

[0022] Such as Figure 1 to Figure 7 shown (for ease of illustration, Figure 1 to Figure 4 Limiting plate, chute and blind hole are not shown), the present invention is a kind of rope ladder storage frame, comprises the rectangular plane base 1 of frame structure, and several plane bases 1 are fixedly connected with several for connecting with spiral on the frame edge The hook 3 that is fastened by the shackle is provided with a railing 4 for the rope ladder to lean against on one side and / or both sides of the planar base 1 in its length direction. The frame edge of the rectangular plane base 1 is composed of four angle steels connected end to end, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com