A visual recognition-based multifunctional weldment processing device and control method

A technology for visual recognition and processing devices, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as low efficiency, inability to switch automatically, and single function, and achieve the effect of solving low efficiency, efficient switching, and efficient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to further understand the present invention, a visual recognition-based multifunctional welding piece processing switching device and its control method provided by the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. The scope of protection of the present invention is not limited to Limitations of the following examples.

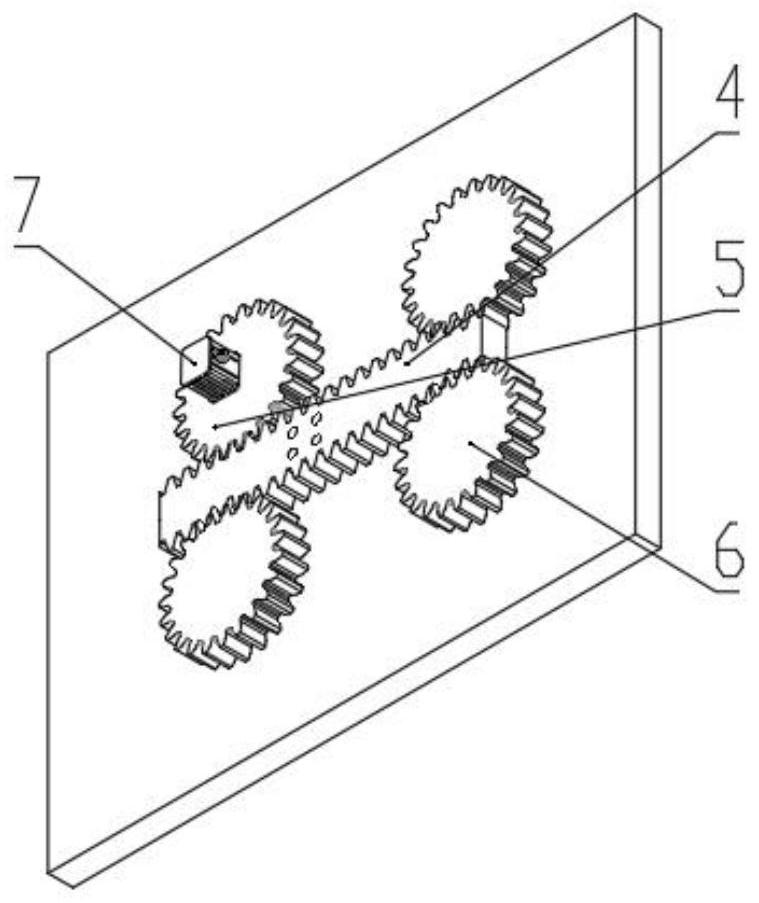

[0039] Such as Figure 1 to Figure 3 As shown, the present invention provides a multifunctional weldment processing device based on visual recognition, including: a switching device, a pre-welding cleaning device 9, a welding device 10 and a post-welding processing device 11; wherein the switching device includes a housing 1, The image acquisition device 3 and the control device; the housing 1 is a hollow triangular prism with two end faces. In order to control the position and movement route of the switching device by controlling the mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com