Automatic gypsum powder dust treatment device

An automatic processing and gypsum powder technology, applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of insufficient suction effect and insufficient suction treatment efficiency, and achieve the effect of sufficient suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

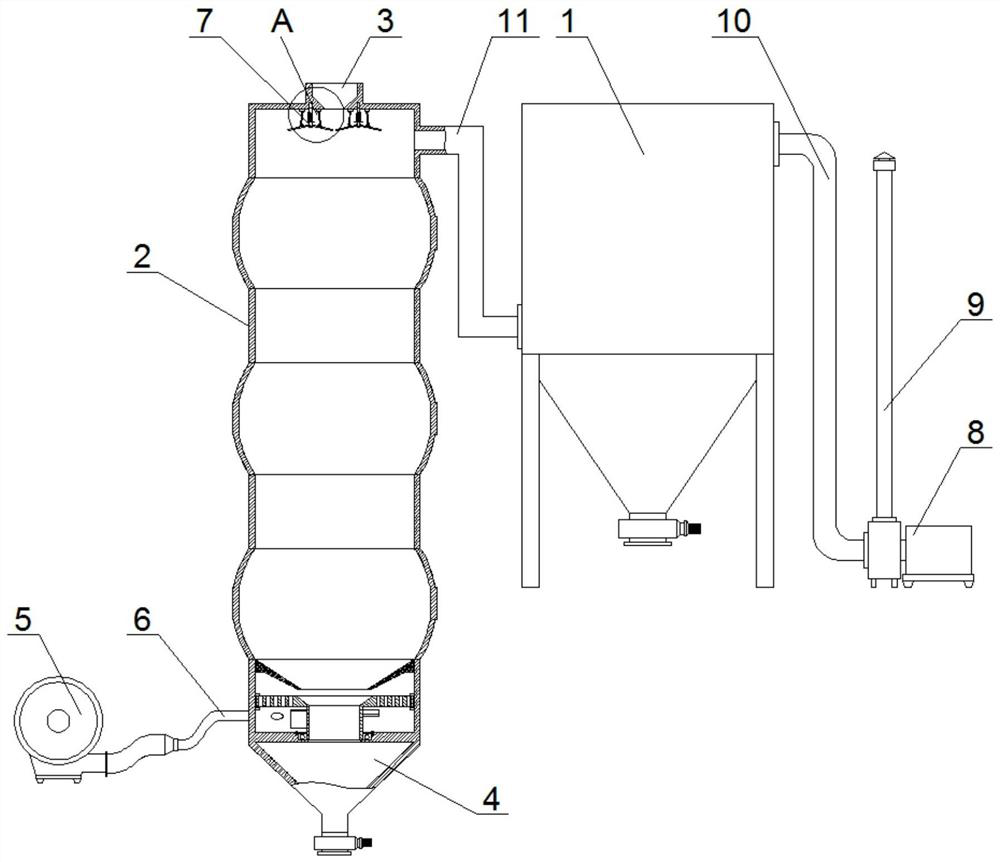

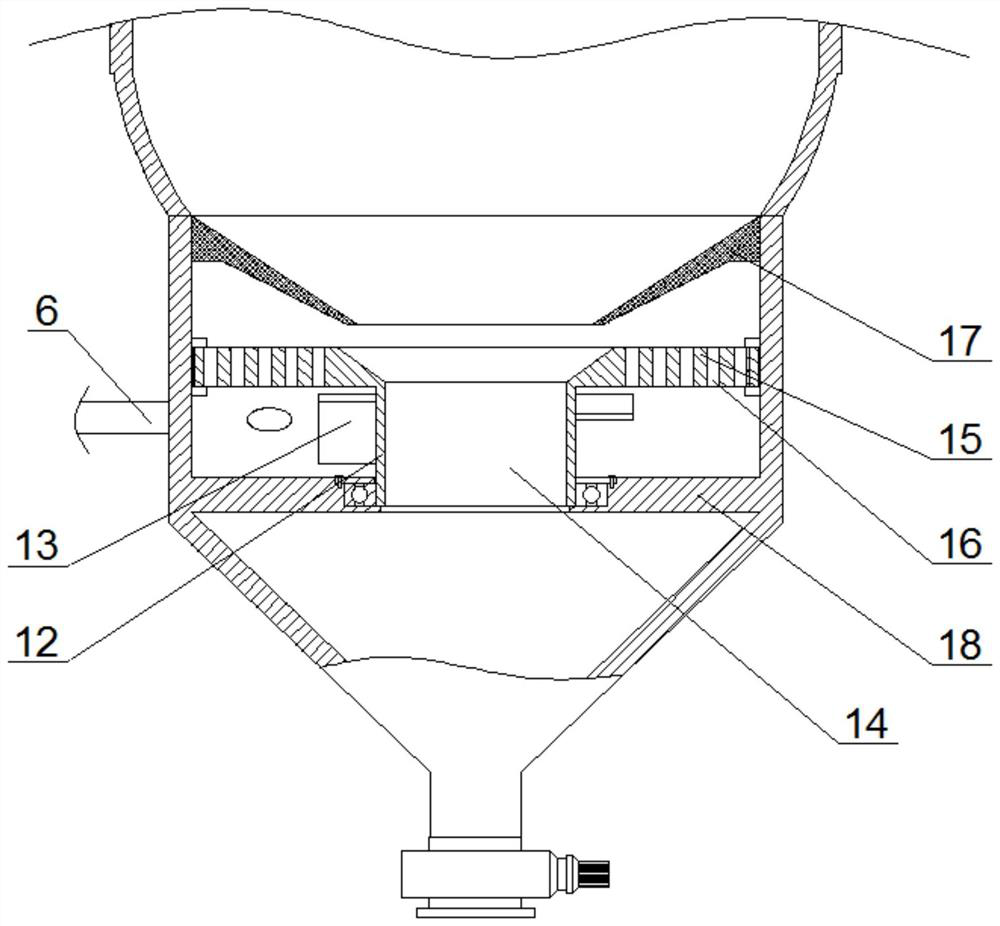

[0022] Please refer to Figure 1 ~ Figure 3 , the present embodiment provides an automatic treatment device for gypsum powder dust, which includes a blower 5, a dust collection cylinder 2, a bag-type dust collector 1 and an exhaust fan 8, the air inlet of the bag-type dust collector 1 and the upper part of the dust collection cylinder 2 A dust exhaust pipe 11 is connected, the inlet of the exhaust fan 8 is connected with the air outlet of the bag filter 1 through an exhaust pipe 10 , and an exhaust pipe 9 is connected to the outlet of the exhaust fan 8 . Start the exhaust fan 8, and the dust exhaust pipe 11 is used as a dust suction channel to draw the gypsum powder dust stuck or stranded in the dust collection tube 2 into the bag type dust collector 1, and then go through multi-layer filtration in the bag type dust collector 1. All the dust is processed and filtered, and the clean air enters the exhaust fan 8 and is finally discharged by the exhaust pipe 9, so as to achieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com