Automatic corn cob steamer

A technology of cooking machine and corn cob, applied in non-electric variable control, simultaneous control of multiple variables, instruments, etc., can solve the problems of inability to control processing parameters in real time, low degree of automation, low processing efficiency, etc., to ensure the utilization rate of heat energy. , The effect of reducing labor cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

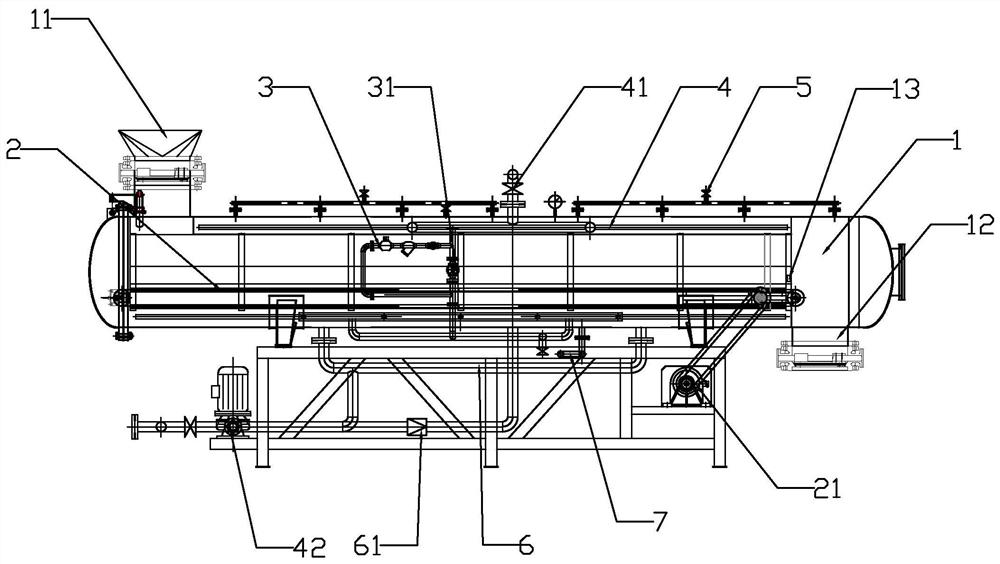

[0033] like figure 1 , image 3 In the shown embodiment, a corn cob automatic cooking machine is applied in the corn cob quick-freezing production line. The corn cob quick-freezing production line includes a bubble cleaning machine, a raw material elevator, a quantitative weighing bucket, a feeding conveyor, an automatic Cooking machine, discharge conveyor, spray cooling hoist, air-cooled pre-cooler and quick-freezing machine, including a cylindrical pot body 1 arranged on a frame 17, and a horizontal conveyor belt 2 is arranged in the pot body 1 along the length direction, The conveyor belt 2 is driven by a frequency conversion transmission reducer 21, and the frequency conversion transmission reducer 21 is controlled by a PLC controller. The top of the pot body 1 is provided with a material inlet 11 corresponding to the front end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com