A modified composite reinforcing material and antibacterial wear-resistant lightweight pallet

A composite reinforcement and modification technology, which is applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve problems such as foam falling off, foam materials are easy to get dirty, and foam materials have weak load-bearing capacity, and achieve improved Smoothness, excellent wear resistance, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

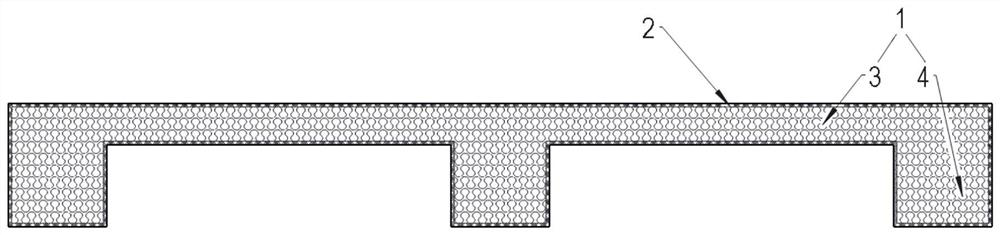

Image

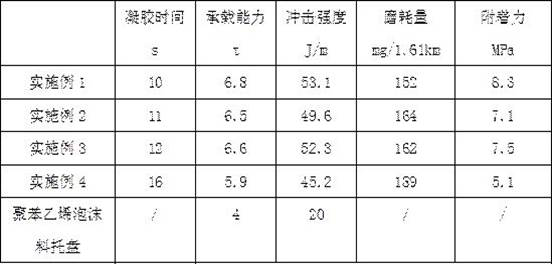

Examples

Embodiment 1

[0042] A kind of antibacterial wear-resisting polyurea elastomer coating of the present embodiment is polyurea resin, and the mass fraction of each component of described polyurea resin is as follows:

[0043] A component

[0044] 40 parts of diphenylmethane diisocyanate (MDI-100);

[0045] 50 parts of polytetrahydrofuran glycol;

[0046] 10 parts of dibutylbenzyl phthalate.

[0047] B component

[0048] Polyether diamine (D-400) 50 parts;

[0049] 30 parts of 4,4'-bis-secondary aminodiphenylmethane;

[0050] 15 parts of methyl hydroxy silicone oil;

[0051] 3.75 parts of nano zinc oxide powder;

[0052] 1.25 parts of chitosan micropowder.

[0053]Modification of nano-zinc oxide: Add absolute ethanol to 2 parts of nano-zinc oxide at a ratio of 1:15, ultrasonically treat for 20 minutes to obtain zinc oxide-ethanol dispersion; then add 0.1 part of coupling agent (KH570 ), mechanically stirred for 10 minutes, then ultrasonically treated at 40-50°C for 1h, heated to 75-85°...

Embodiment 2

[0058] A kind of antibacterial wear-resisting polyurea elastomer coating of the present embodiment is polyurea resin, and the mass fraction of each component of described polyurea resin is as follows:

[0059] A component

[0060] Toluene diisocyanate (TDI) 40 parts;

[0061] 55 parts of polytetrahydrofuran glycol;

[0062] 5 parts of dibutylbenzyl phthalate.

[0063] B component

[0064] 55 parts of polyether diamine (T-403);

[0065] 30 parts of diaminodimethylthiotoluene;

[0066] 10 parts of methyl hydroxy silicone oil;

[0067] 3.85 parts of nano zinc oxide powder;

[0068] 1.15 parts of chitosan micropowder.

[0069] Modification of nano-zinc oxide: Add absolute ethanol to 2 parts of nano-zinc oxide at a ratio of 1:15, and ultrasonically treat for 20 minutes to obtain a zinc oxide-ethanol dispersion; the coupling agent is KH570. Then add 0.1 part of coupling agent to the zinc oxide-ethanol dispersion, stir mechanically for 10 minutes to mix, then ultrasonically t...

Embodiment 3

[0074] A kind of antibacterial wear-resisting polyurea elastomer coating of the present embodiment is polyurea resin, and the mass fraction of each component of described polyurea resin is as follows:

[0075] A component

[0076] 55 parts of diphenylmethane diisocyanate (MDI-100);

[0077] 40 parts of tetrahydroxypropyl ethylenediamine;

[0078] 5 parts of dibutylbenzyl phthalate.

[0079] B component

[0080] 45 parts of polyether diamine (D-230);

[0081] 35 parts of diaminodimethylthiotoluene;

[0082] 15 parts of methyl hydroxy silicone oil;

[0083] 4.5 parts of nano zinc oxide powder;

[0084] Chitosan micropowder 0.5 part.

[0085] Modification of nano-zinc oxide: Add absolute ethanol to 2 parts of nano-zinc oxide at a ratio of 1:15, and ultrasonically treat for 20 minutes to obtain a zinc oxide-ethanol dispersion; the coupling agent is KH570. Then add 0.1 part of coupling agent to the zinc oxide-ethanol dispersion, stir mechanically for 10 minutes to mix, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com