Electrical connector structure

A technology of electrical connectors and terminals, which is applied in the field of electrical connector structures, and can solve problems such as inconvenient use, falling off of terminal seats, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

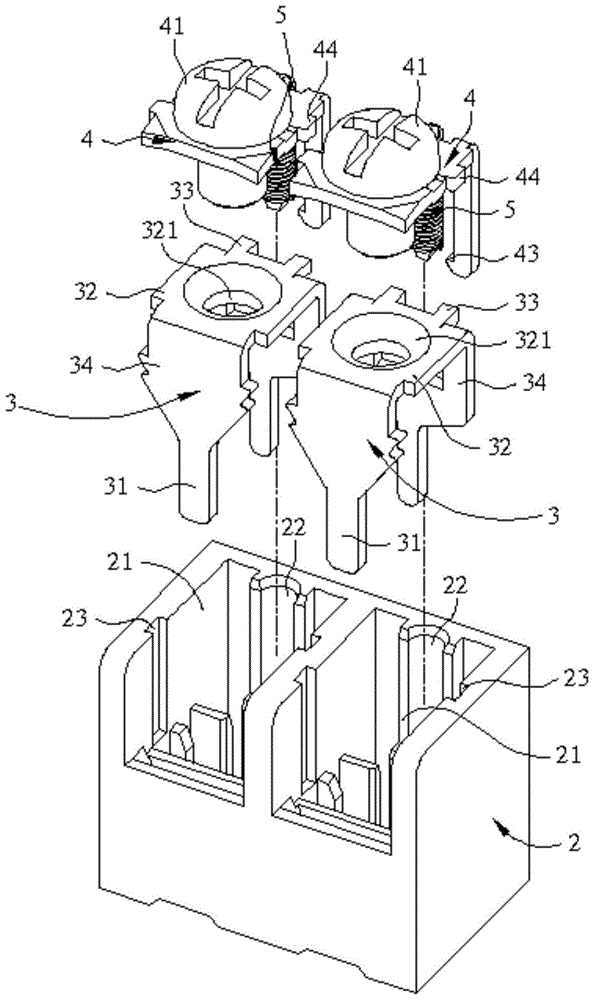

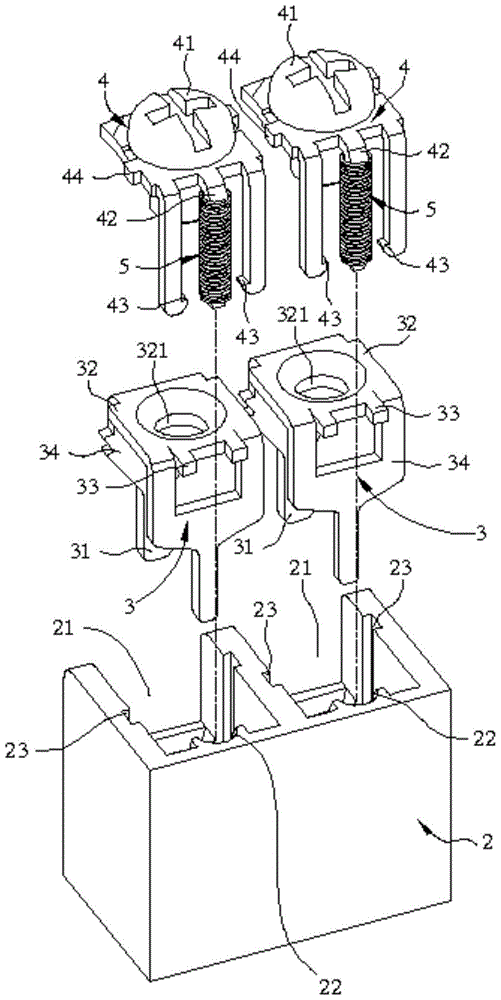

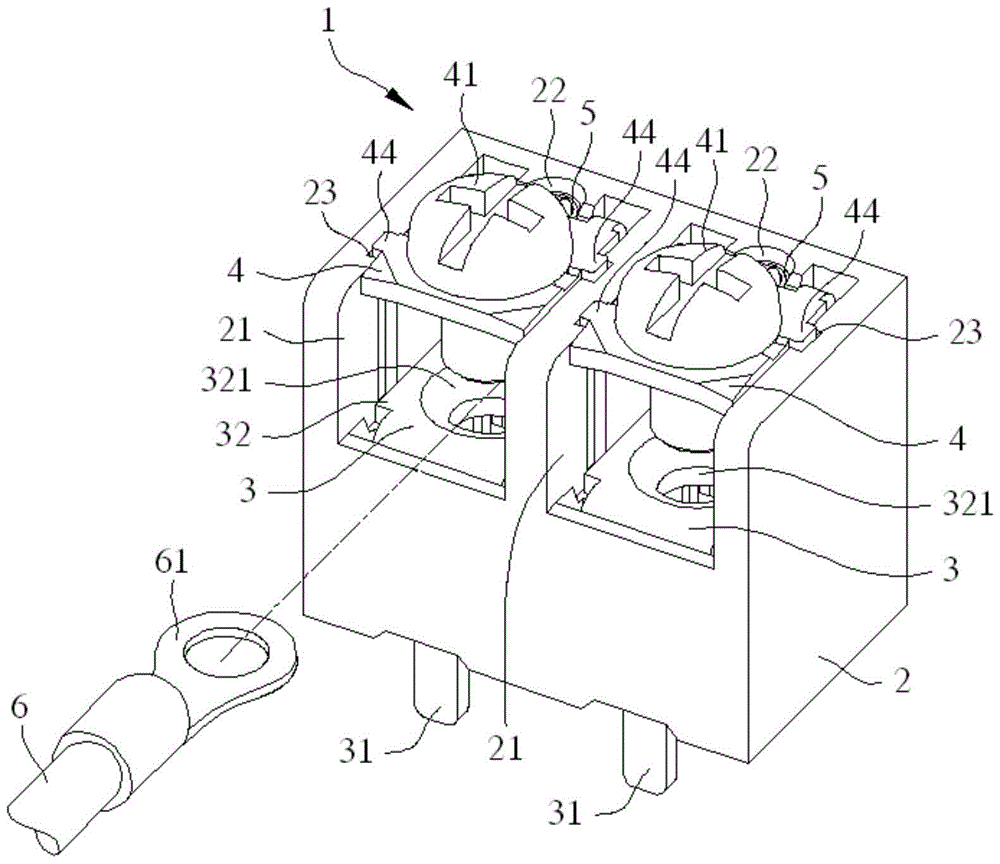

[0034] Such as figure 1 and figure 2 As shown, an electrical connector structure 1 includes a body 2, and at least one longitudinal slot 21 is opened on the body 2; corresponding to each slot 21, a terminal lower seat 3, a terminal upper seat 4 and an elastic piece 5. The terminal lower seat 3 includes a terminal surface 32 formed by extending transversely, and the terminal surface 32 is longitudinally provided with a screw hole 321; corresponding to the screw hole 321, the terminal upper seat 4 has a screw fitting 41; the terminal lower seat 3 and the terminal upper seat 4 are longitudinally arranged In the corresponding slot 21, and the terminal upper seat 4 can move longitudinally relative to the terminal lower seat 3, so that the screw 41 is screwed into and screwed out of the screw hole 321; the elastic member 5 is arranged in the slot 21 and is pressed against the body 2 and the terminal upper seat 4; when the screw fitting 41 is screwed out of the screw hole 321, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com