Visual inspection error prevention system and position correction method for articles transported by conveyor belt

A visual detection and error prevention technology, applied in conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems that affect the detection of the visual system, the visual system cannot be applied, and the edge cannot be judged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

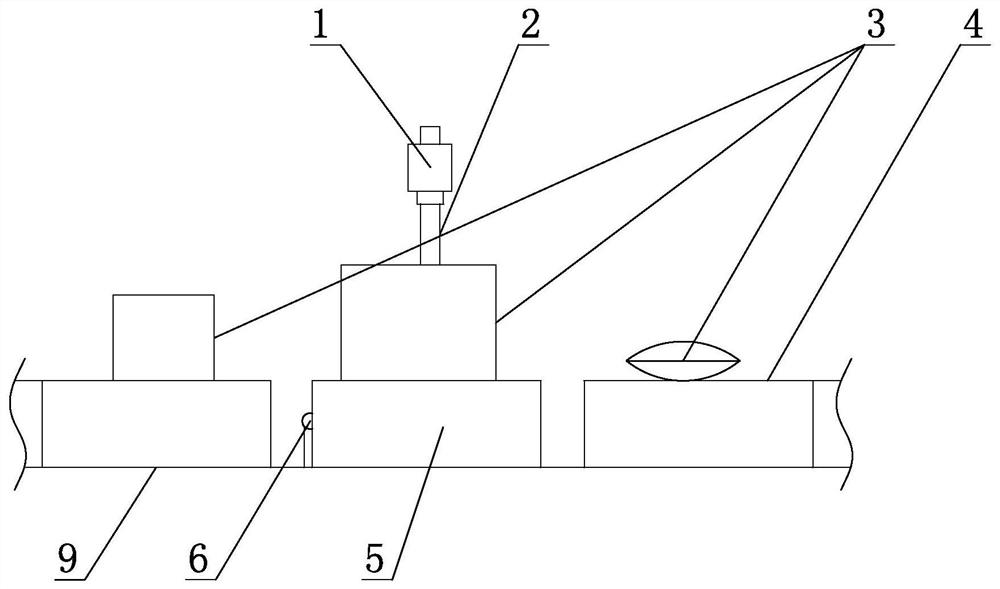

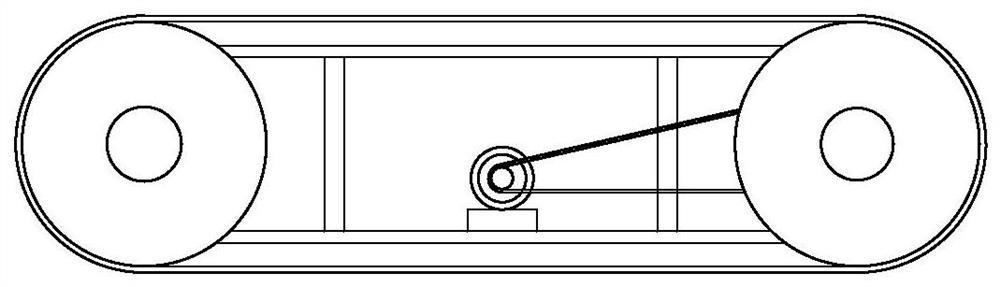

[0064] Embodiment 1: As shown in the figure, the visual detection error prevention system according to the present invention includes a camera 1, and the camera 1 is erected above the transportation device through the camera bracket 2, and the transportation device can be a carrier trolley, a conveyor belt, or a logistics sorting system 4 , the carrying platform of the transportation device is the top platform of the carrying trolley, the belt of the conveyor belt, and the belt of the sub-conveyor belt 5 of the logistics sorting system. This application takes the belt of the sub-conveyor belt 5 of the logistics sorting system as an example to explain. The color of the belt is more than one, and the specific application is two. The two colors are arranged on the belt alternately. The communication line of the camera 1 is connected to the controller. Communication terminal, the communication terminal of the controller is connected to the control system of the transport device;

...

Embodiment 2

[0069] Embodiment 2: The visual detection error prevention system of the present invention includes a camera 1, and the camera 1 is erected above the transport device through the camera bracket 2. The transport device can be a carrying trolley, a conveyor belt, and a logistics sorting system 4. The carrying of the transport device The platform is the top platform of the carrying trolley, the belt of the conveyor belt, and the belt of the sub-conveyor belt 5 of the logistics sorting system. This application takes the belt of the sub-conveyor belt 5 of the logistics sorting system as an example to explain. The color of the belt is more than one, and the specific application is two. The two colors are arranged on the belt alternately. The communication line of the camera 1 is connected to the controller. Communication terminal, the communication terminal of the controller is connected to the control system of the transport device;

[0070] A sensing device is provided, the sensin...

Embodiment 3

[0074] Embodiment 3: The visual detection error prevention system of the present invention includes a camera 1, and the camera 1 is erected above the transport device through the camera bracket 2. The transport device can be a carrying trolley, a conveyor belt, and a logistics sorting system 4. The carrying of the transport device The platform is the top platform of the carrying trolley, the belt of the conveyor belt, and the belt of the sub-conveyor belt 5 of the logistics sorting system. This application takes the belt of the sub-conveyor belt 5 of the logistics sorting system as an example to explain. The color of the belt is more than one, and the specific application is two. The two colors are arranged on the belt alternately. The communication line of the camera 1 is connected to the controller. Communication terminal, the communication terminal of the controller is connected to the control system of the transport device;

[0075] A sensing device is provided, the sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com