Novel anti-breakdown downpipe

An anti-breakdown, downspout technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, pipes for emptying/ballasting, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

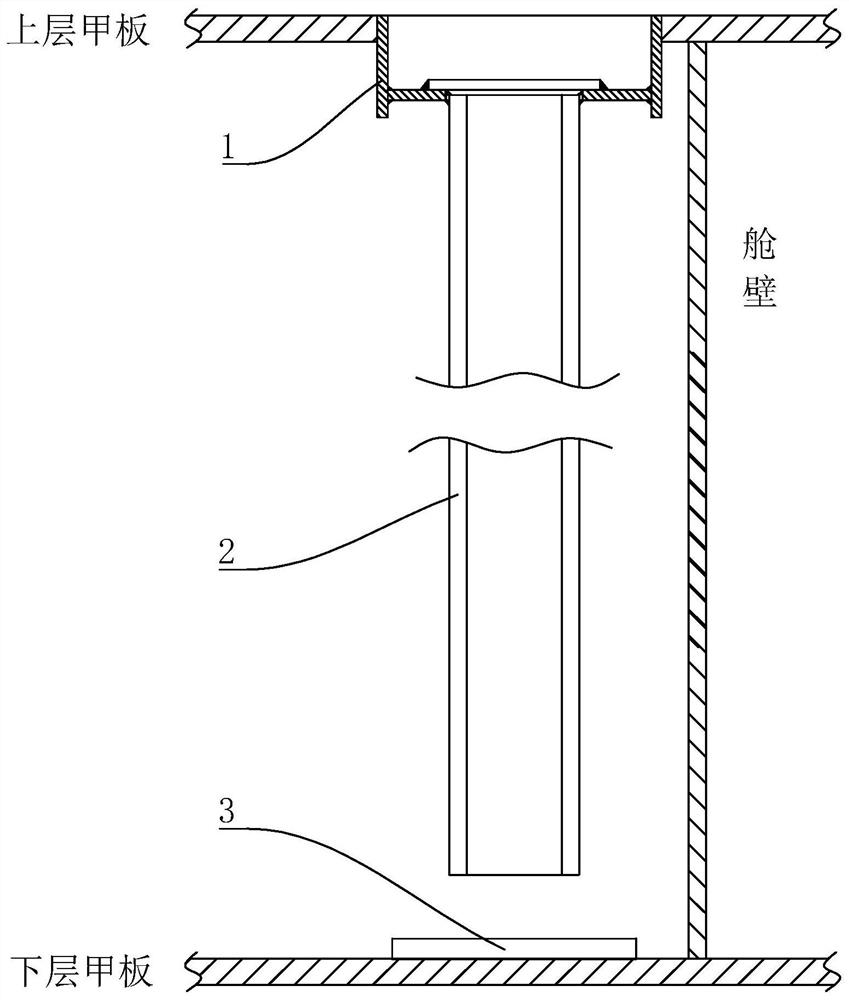

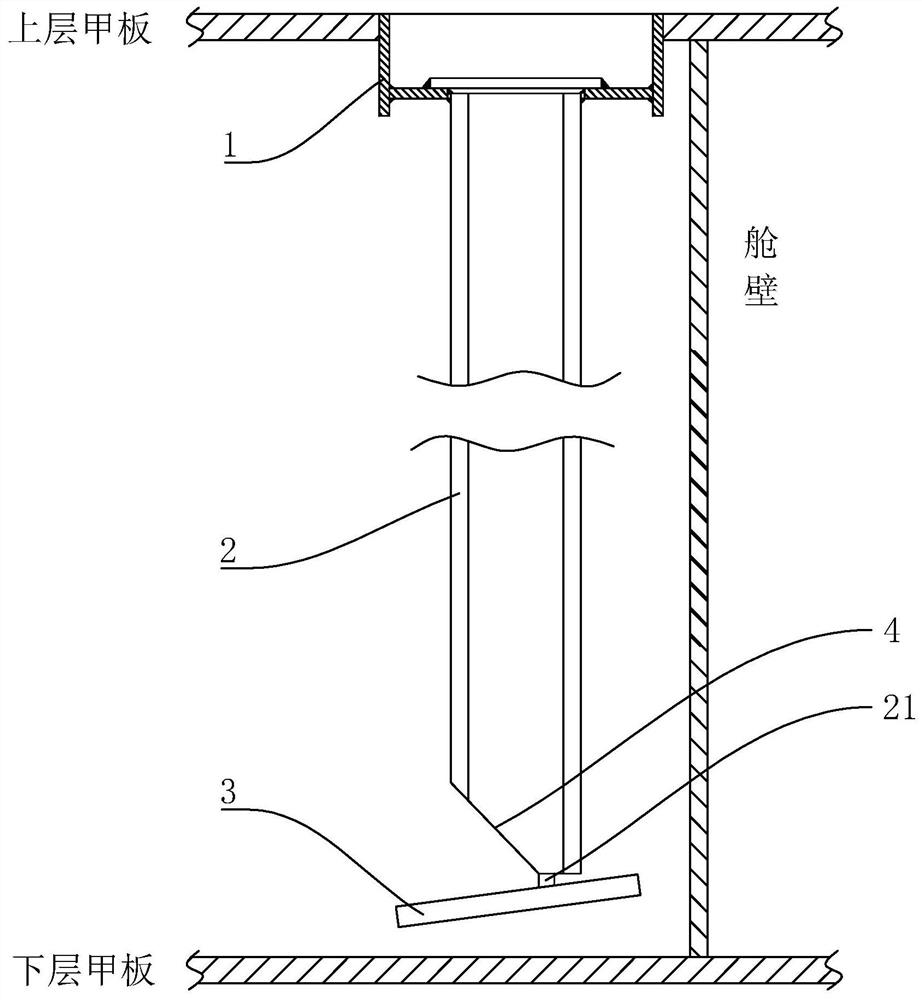

[0023] A new anti-puncture downspout provided in this embodiment has a structure such as Figure 2 to Figure 4 As shown, it includes a drain 1 located on the upper deck, the lower end of the drain 1 is connected with a vertical pipe body 2, and the lower end of the pipe body 2 is detachably connected with a strike plate 3, and the lower end of the pipe body 2 is also opened. There are inclined openings 4 .

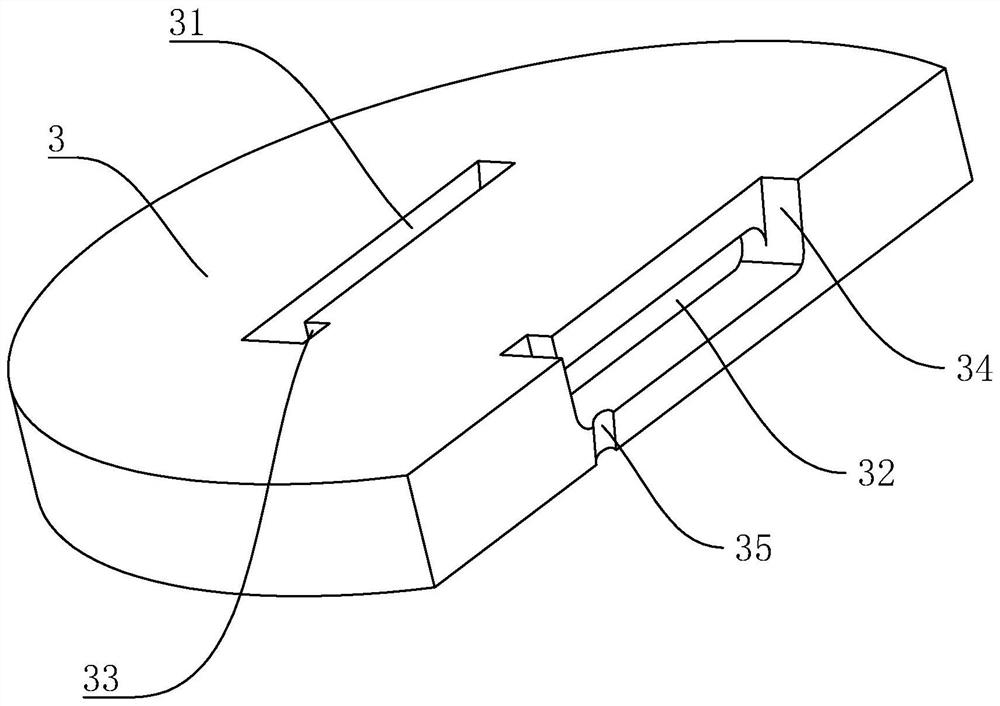

[0024] The bottom end of the pipe body 2 is provided with two sliding columns 21 at intervals, and the two sliding columns 21 are arranged symmetrically along the diameter direction of the pipe body 2, and the two sliding columns 21 are arranged to be parallel to each other; the bottom of the sliding columns 21 A rotating column 22 is fixed, and the rotating column 22 is arranged on the side of the bottom of the sliding column 21 close to the other sliding column 21, and the two rotating columns 22 are arranged symmetrically along the diameter direction of the pipe body 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com