A high-strength aluminum alloy light truck frame and its manufacturing method

A technology of aluminum alloy and light truck, applied in the direction of manufacturing tools, improvement of process efficiency, furnace, etc., can solve the problems of complex structure of the middle beam, inconvenient installation and disassembly, high density of high-strength steel, etc., so as to increase the bearing weight and facilitate the replacement of parts , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 introduces a high-strength aluminum alloy light truck frame. The aluminum alloy frame has a simple structure, light weight and convenient installation, which can increase the effective carrying weight of the vehicle and improve the economic benefits of transportation. The details are as follows:

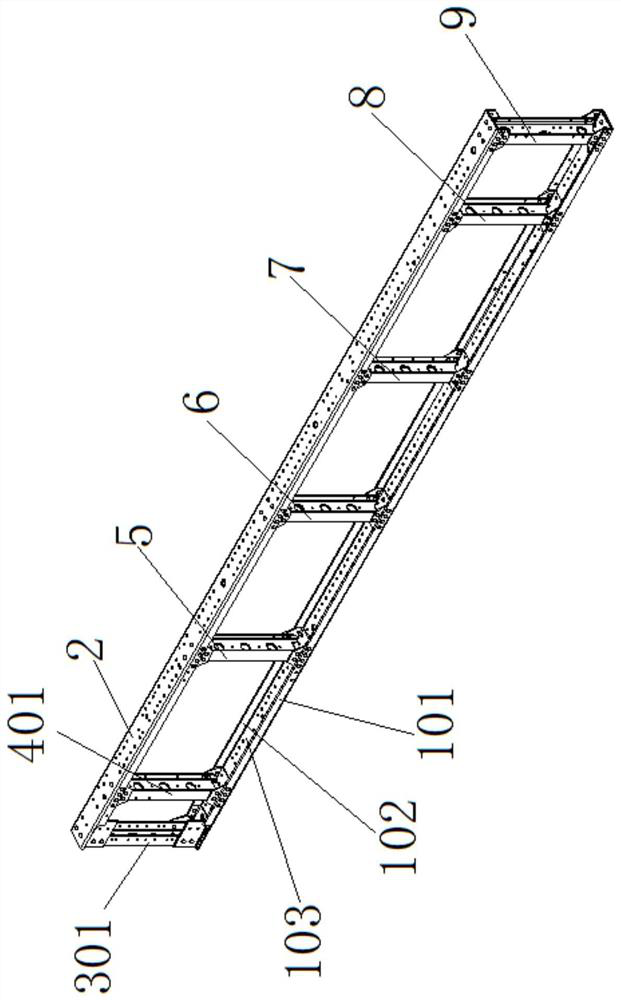

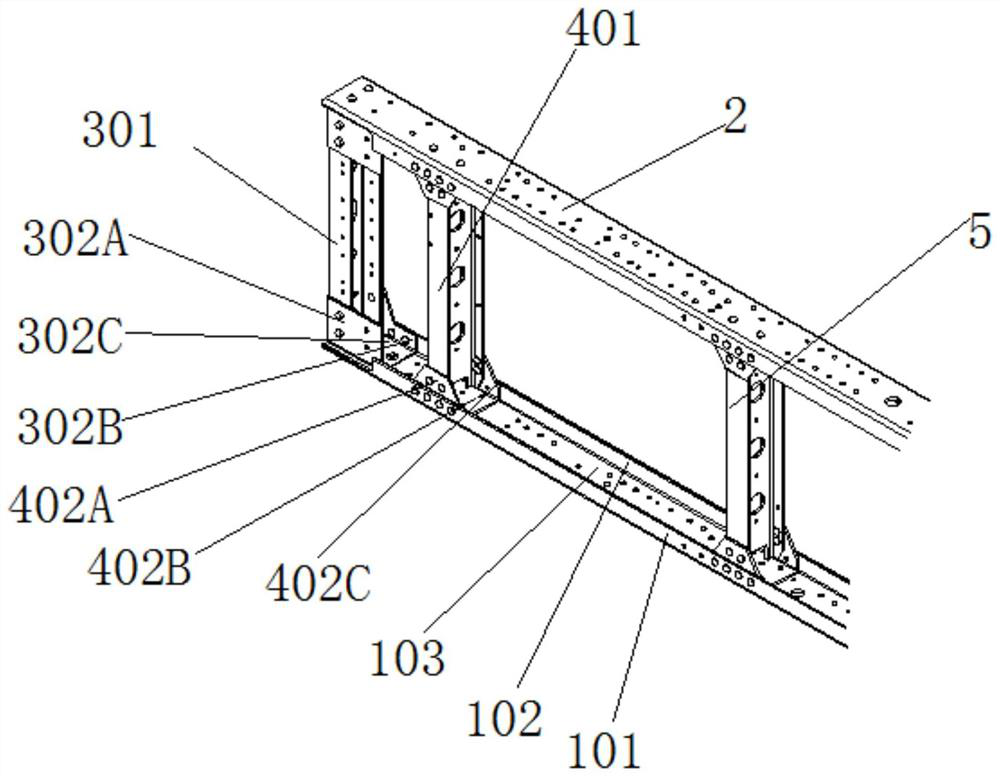

[0035] see figure 1, a high-strength aluminum alloy light truck frame and its raw material components and heat treatment process, the frame includes a left longitudinal beam 1, a right longitudinal beam 2, a first beam assembly 3, a second beam assembly 4, and a third beam assembly 5. The fourth crossbeam assembly 6, the fifth crossbeam assembly 7, the sixth crossbeam assembly 8 and the seventh crossbeam assembly 9; the left longitudinal beam 1 includes the upper wing surface 101, the lower wing surface 102 and the side wing surface 1 103. The structure of the left longitudinal beam 1 and the right longitudinal beam 2 is symmetrical; the difference between the dia...

Embodiment 2

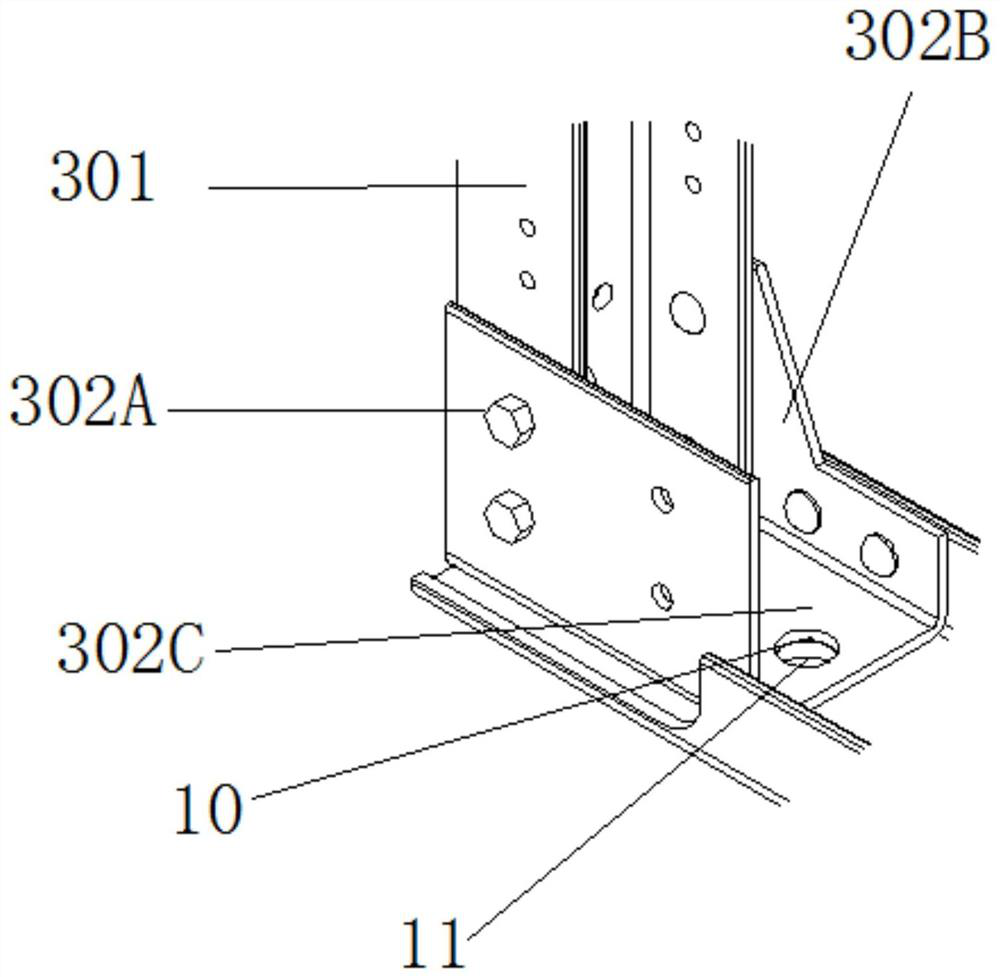

[0038] Embodiment 2 is an improvement on the basis of Embodiment 1. The main improvement is that a riveting hole 10 is provided on the flank surface 103, and a riveting hole 10 is provided on the flank surface 2 302C and the flank surface 3 402C. Matching riveting hole two 11, finally pass through riveting hole one 10 and riveting hole two 11 through the self-locking nut to realize the fixed connection of flank surface two 302C and flank surface three 402C with flank surface one 103 respectively, and improve the first beam assembly 3, The second crossbeam assembly 4, the third crossbeam assembly 5, the fourth crossbeam assembly 6, the fifth crossbeam assembly 7, the sixth crossbeam assembly 8 and the seventh crossbeam assembly 9 respectively left longitudinal beam 1 and right longitudinal beam 2 The firmness of the connection. The specific improvements are as follows:

[0039] see figure 1 , a high-strength aluminum alloy light truck frame and its raw material components and...

Embodiment 3

[0042] Embodiment 3 is to further illustrate the preparation material and heat treatment process of vehicle frame on the basis of embodiment 2, specifically as follows:

[0043] The preparation material of the frame is composed of the following mass percentage components: 0.001% silicon, 0.04% zirconium, 4.0% zinc, 0.001% iron, 0.001% manganese, 1.0% magnesium, 1.0% copper and 0.001% % of impurity elements, the rest is metallic aluminum;

[0044] In the heat treatment process, the slag and oxidation residues must be thoroughly cleaned before melting the crucible, and the auxiliary melting tools used must completely remove aluminum alloy residues, lagging paint and oxidation residues; the heat treatment process of aluminum alloy frame includes the following steps:

[0045] Step 1, the quenching temperature is 460°C, and water is used as the quenching agent;

[0046] Step 2, natural aging of the workpiece after quenching for 1.0h;

[0047] Step 3: Heat the workpiece after stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com