Superimposed board production line

A laminated board and production line technology, which is applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of large floor area, long maintenance and forming time, and reduced production efficiency of laminated boards, so as to reduce the occupied area The effect of reducing the area and shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

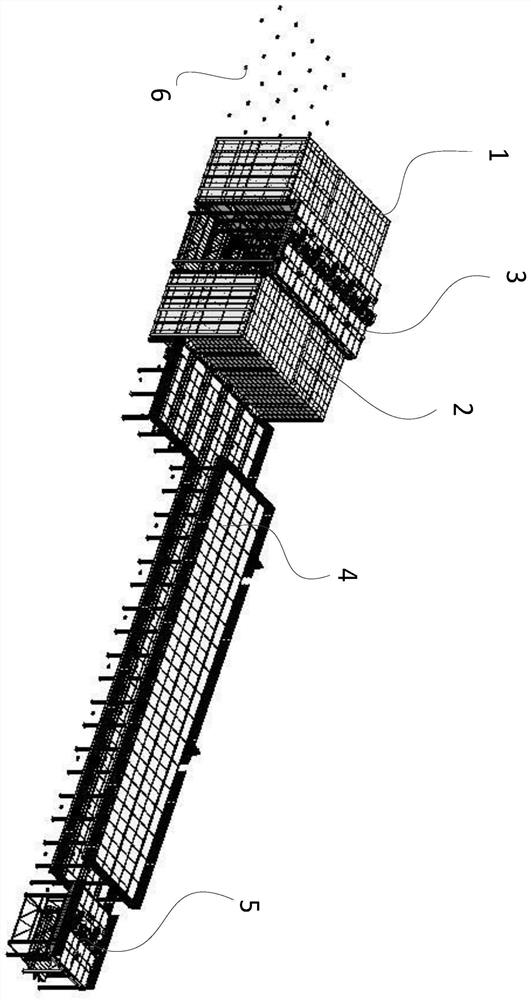

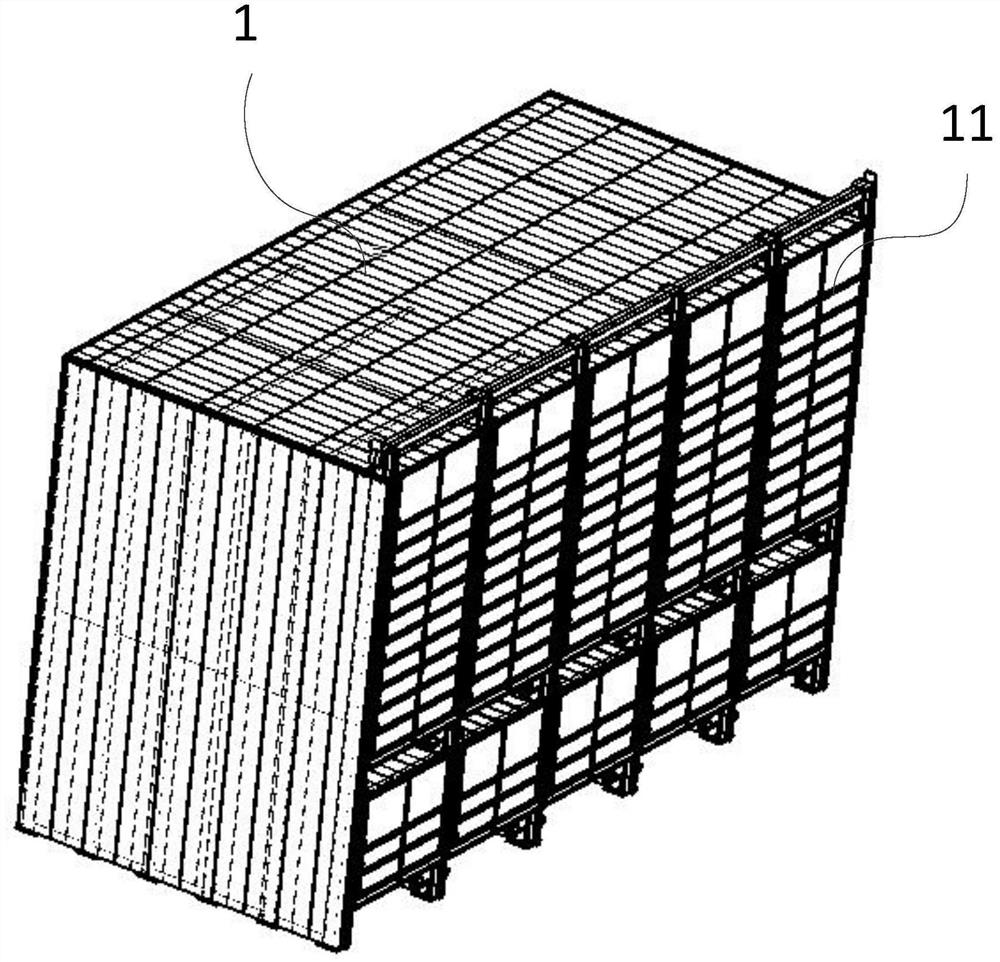

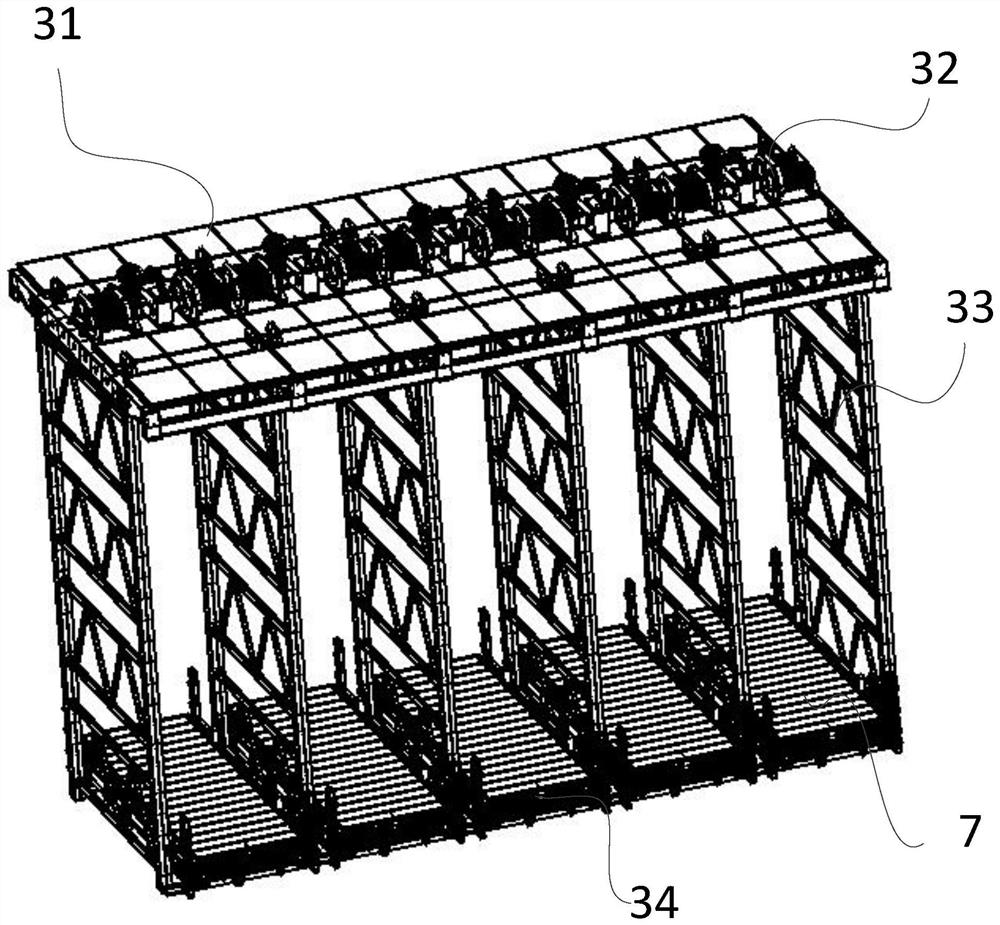

[0053] Such as Figure 1 to Figure 20 As shown, this embodiment provides a laminated slab production line, which is used to transfer the mold box 7 in the assembly line, and perform pouring, molding and maintenance of the laminated slabs in the mold box 7 . The laminated board production line includes a first steaming room 1 and a second steaming room 2 with opposite openings, which are sandwiched between the first steaming room 1 and the second steaming room 2 for hoisting the mold box 7 into the , hang out the first lifting mechanism 3 of the first steaming room 1 and the second steaming room 2, communicate with the second steaming room 2, and be used to transport the mold box for placing the steel frame mold tire and pouring concrete into a laminated plate The double-deck delivery platform 4 of 7 is connected with the double-deck delivery platform 4, is used for the second elevating mechanism 5 of the up-and-down transposition of the mold box 7 on the double-layer delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com