Three-degree-of-freedom bionic neck movement mechanism

A motion mechanism and degree-of-freedom technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low degree of bionics, insufficient flexibility and coordination of three degrees of freedom, inflexible operation and use, etc. Flexible, highly bionic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

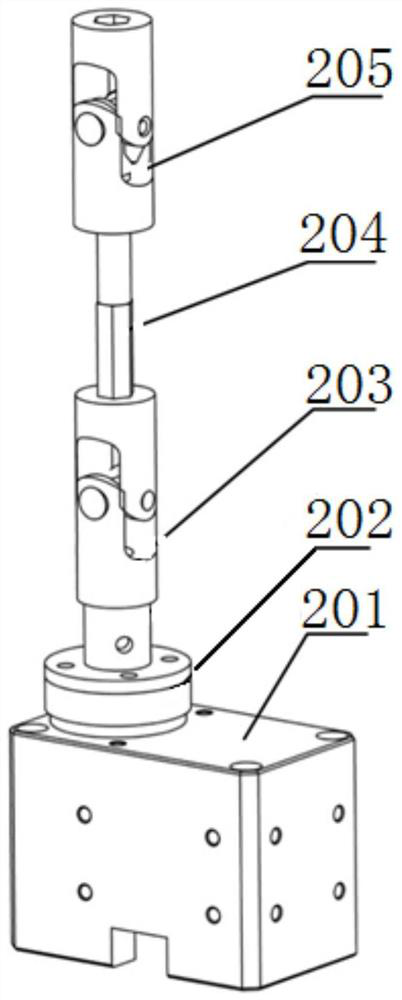

[0024] Such as figure 1 As shown, it is a three-degree-of-freedom bionic neck movement mechanism, which includes a base 1 and a twisting mechanism 2, a pitching mechanism 4, a side swing mechanism 3 and a connecting slider 7, which include a support 701, the roller 702 and the head and neck connector 703, the roller 702 is arranged at one end of the support 701, and one end of the head and neck connector 703 is movably installed on the other end of the support 701, and the side swing mechanism 3 includes a pitch track used in conjunction with the roller 702 301 and the side swing assembly that is located on the base 1 and can drive the swing track 301 to swing. The connecting slider 7 is rollingly connected to the pitch track 301 through the roller 702. The pitch mechanism 4 includes a side swing head 401 and a swing head that can drive the side swing head 401 The pitch assembly 6, the swing plane of the side swing head 401 is perpendicular to the swing plane of the pitch trac...

Embodiment 2

[0033] This embodiment is similar to embodiment 1, and its difference is:

[0034] The first driving device 201 , the second driving device 305 and the third driving device 406 are all geared motors; the geared motors can perform the most basic transmission function and are cost-effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com